Youngs Modulus Study Tutorial

This section will walk you through the steps of creating Youngs Modulus variation study setup.

View new features for Engineering Solutions 2021.

HyperWorks Engineering Solutions is a modeling and visualization environment for NVH, Crash, CFD, Drop Test and Aerospace using best-in-class solver technology.

Discover Engineering Solutions functionality with interactive tutorials.

Noise, Vibration and Harshness (NVH) is an important vehicle attribute that directly affects the customer experience.

Use Squeak and Rattle Director tool to create evaluation lines, evaluate them and optimize the interfaces to eliminate squeak and rattle issues.

Details about the strengths of SnRD as a tool.

Use of Altair Ziegler SnR Material Database.

The process involved in SnRD workflows.

Below is the list of files required to complete the tutorial activity for the various usecases:

The workflows risk and analysis of squeak and rattle issues.

You will evaluate model for SnR issues for dynamic/transient loading condition.

You will evaluate SnR issues for static/touch point locations.

to evaluate SnR issues when system is imposed with multiple loading conditions,. I.e vehicle is parked under direct sunlight and is driven off.

to forecast the SnR issues in the systems based on the manufacturing variations like, component thickness, attachment stiffness, modal damping and etc.

The Crash application offers a tailored environment in HyperWorks that efficiently steers the Crash CAE specialist in CAE model building, starting from CAD geometry and finishing with a runnable solver deck in Radioss, LS-DYNA and PAM-CRASH 2G.

HyperWorks offers high quality tools for CFD applications enabling the engineer to perform modeling, optimization and post-processing tasks efficiently.

The Drop Test Manager is an automated solution that allows you to either simulate a single drop test or a choice of multiple iterations with the aim of finding the sensitivity of process variables like initial orientation and drop height in a typical drop test by controlling the run parameters and conditions with ease.

Many essential utility tools using HyperWorks-Tcl have been developed over the years to support Aerospace customers. A few tools have been collected and upgraded to be compatible with this release.

Solver interfaces supported in Engineering Solutions.

A solver interface is made up of a template and a FE-input reader.

Support provided by the CAD readers and writers.

Browsers supply a great deal of view-related functionality in Engineering Solutions by listing the parts of a model in a tabular and/or tree-based format, and providing controls inside the table that allow you to alter the display of model parts.

Panels contains pre-processing and post-processing tools.

Create, edit, and cleanup geometry.

Learn about the different types of mesh you can create in HyperWorks.

Create connections between parts of your model.

Create, organize, and manage the CAE parts.

Perform automatic checks on CAD models, and identify potential issues with geometry that may slow down the meshing process using the Verification and Comparison tools.

Overview of how to build a finite element model.

Morph the shape of your finite element model.

Setup an Optimization in Engineering Solutions.

Convert finite element models to another solver format.

Study relationships between data vectors in results files.

Learn how to use post-processing functions.

Use Squeak and Rattle Director tool to create evaluation lines, evaluate them and optimize the interfaces to eliminate squeak and rattle issues.

The process involved in SnRD workflows.

The workflows risk and analysis of squeak and rattle issues.

to forecast the SnR issues in the systems based on the manufacturing variations like, component thickness, attachment stiffness, modal damping and etc.

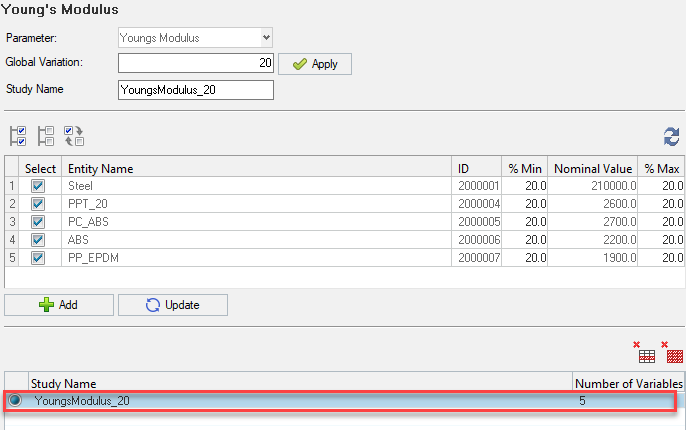

This section will walk you through the steps of creating Youngs Modulus variation study setup.

20 as the value for Global Variation

% and click Apply

20 as the default value for all the

materials listed in the table.Study Name and the Number of Variables

(c) 2021. Altair Engineering Inc. All Rights Reserved.