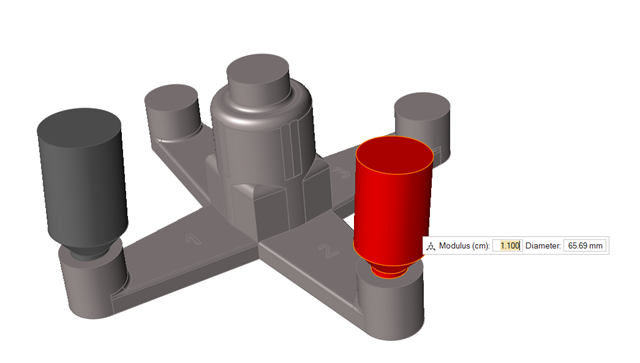

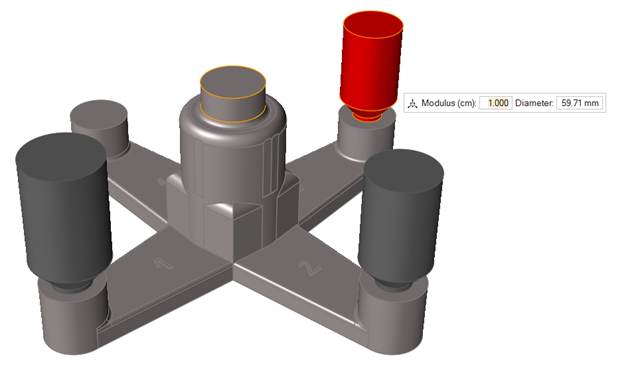

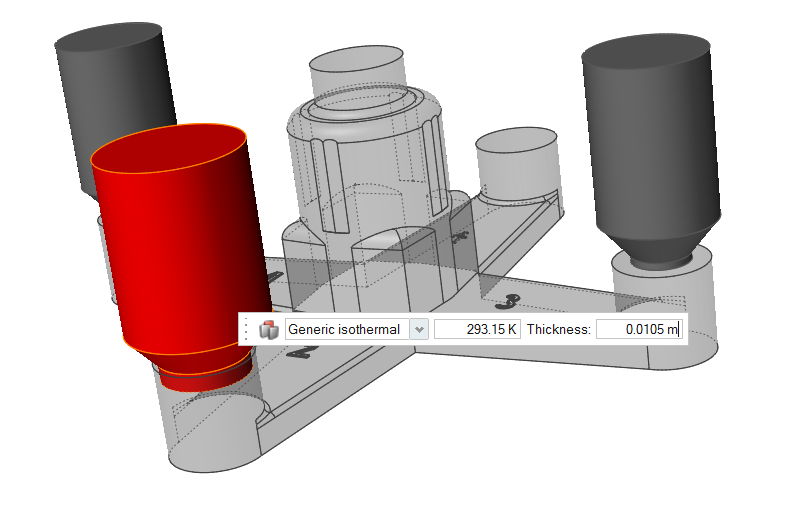

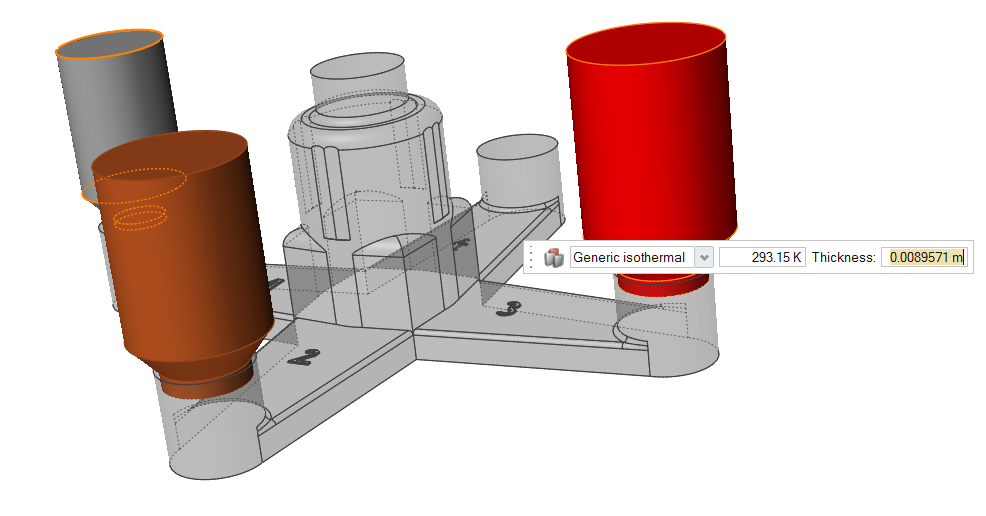

Tutorial: Sleeve Component

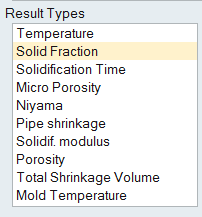

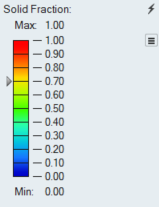

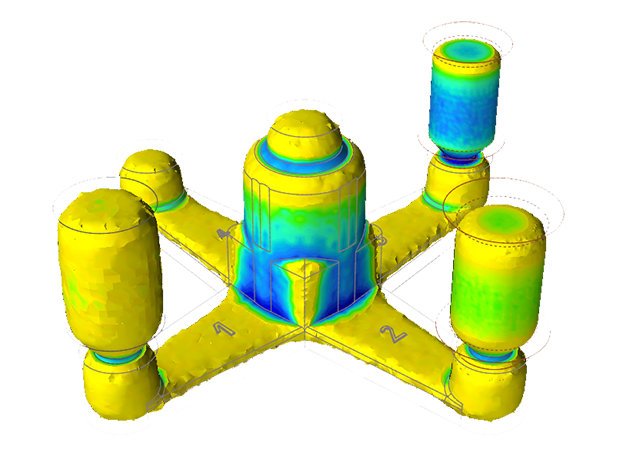

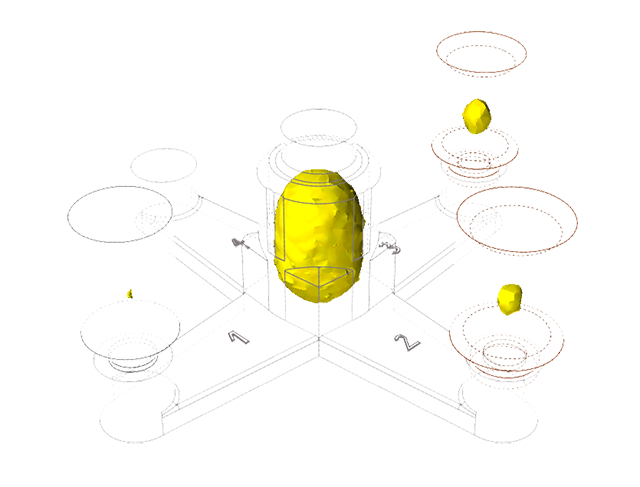

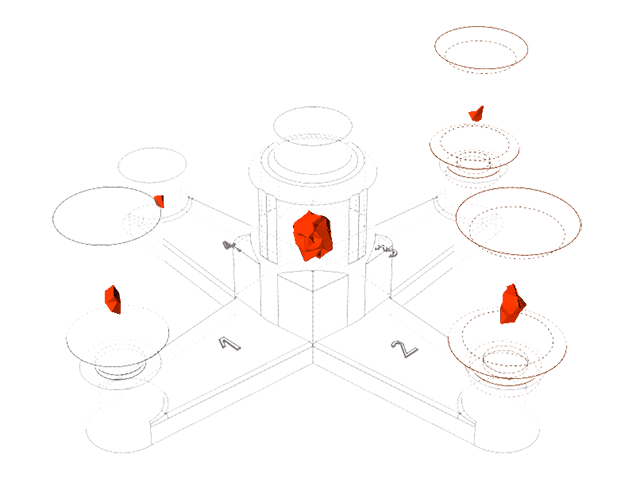

Compare the solidification in a riser with that of risers with isothermal and exothermal sleeves.

In this exercise, you will learn how to analyze the effect a sleeve has on casting.

Model file is available in the tutorial_models folder in the installation directory in Program Files\Altair\2021\InspireCast2021\tutorial_models\sleeve.x_b.

Import Geometry

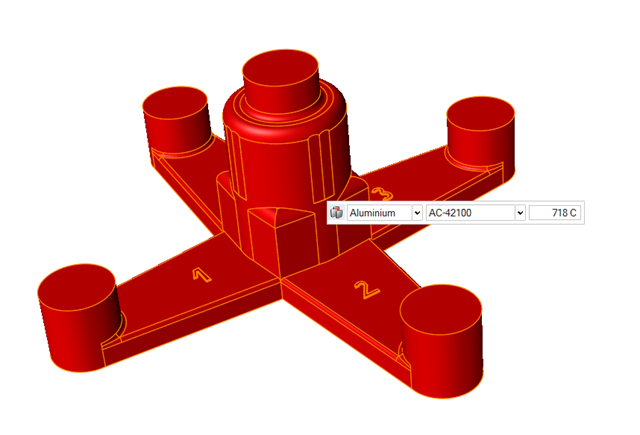

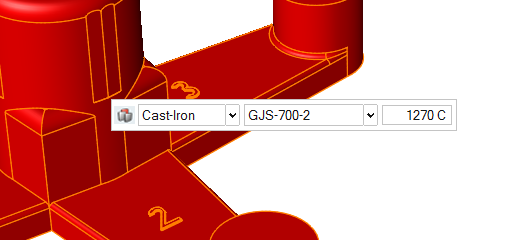

Designate a Casting Part

on the

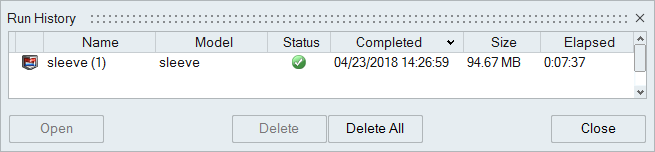

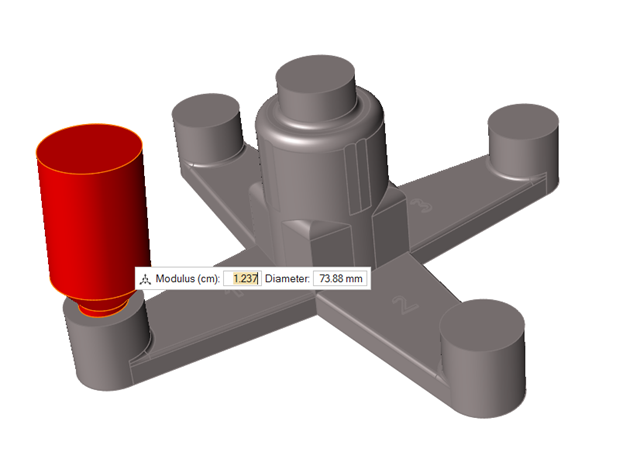

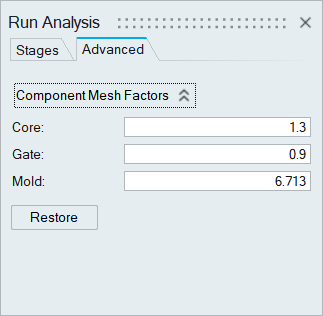

Analyze

on the

Analyze  tool.

tool.