Support

Create and partition supports required for 3D printing.

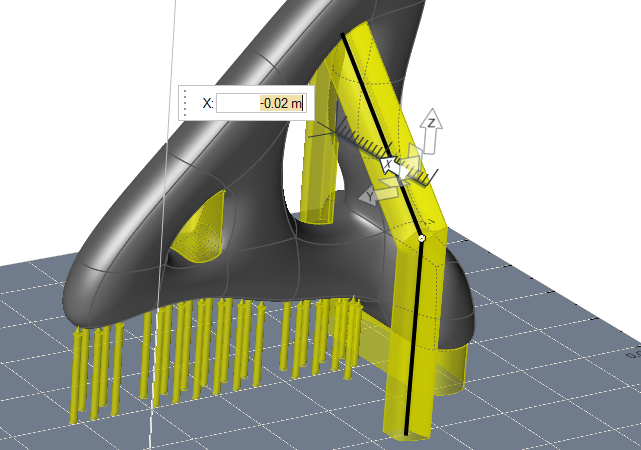

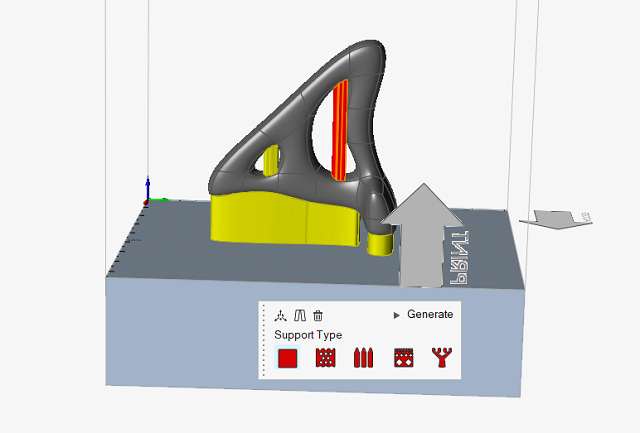

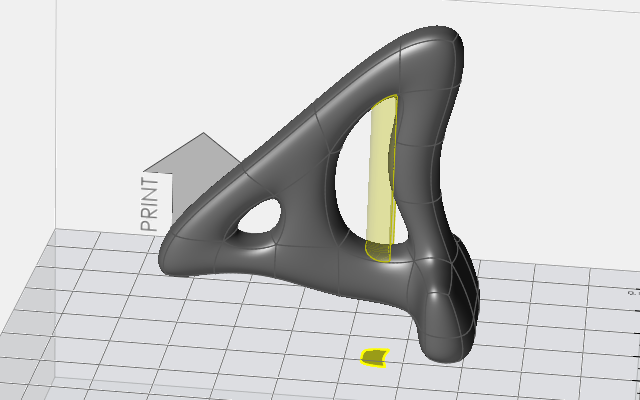

When 3D printing a part, surfaces on the part with angles of less than 45 degrees require support material to be added during the printing process. These areas are highlighted in yellow when the Orientation or Support tools are selected.

Use the Supports

![]() tool to:

tool to:

- Automatically generate and edit supports

- Manually create a support in a specific region

- Move and partition supports so they are placed optimally for 3D printing

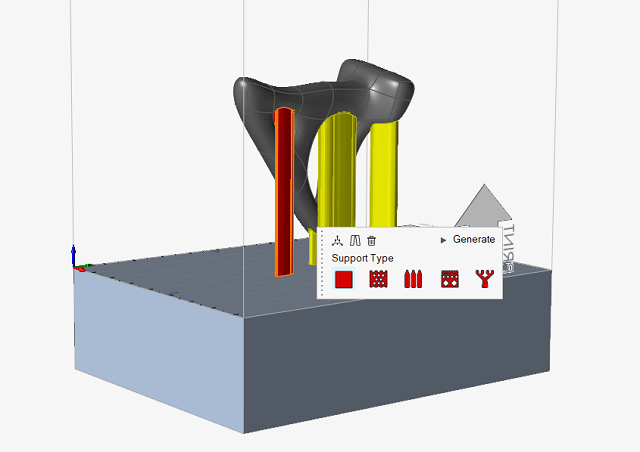

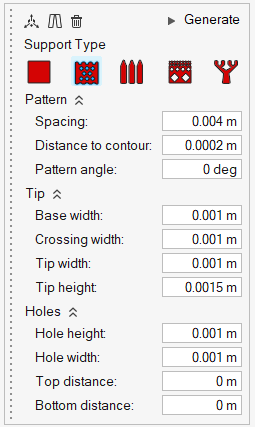

Automatically Generate Supports

Auto-generate support for the part with material that will be removed during post-processing.

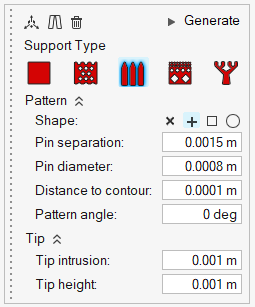

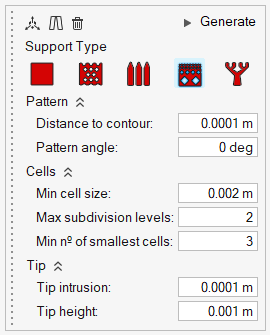

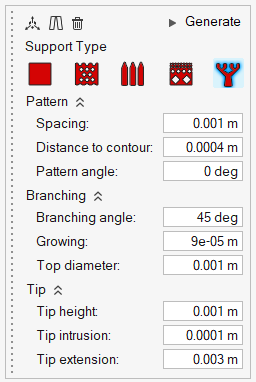

- Hover over a parameter in the supports microdialog to view a tooltip that explains what the parameter does.

- Use the Minimum support area option in the Preferences to define the smallest area for which supports should be generated. Areas smaller than this will be assumed to be self-supporting due to their small size and will not display a support preview, even if one would generally be required due to the undercut angle.

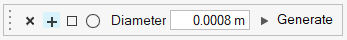

Manually Create a Support

Create supports manually in any region of the part based on your specific requirements.

-

Select the Manual Supports

tool on the Support icon.

tool on the Support icon.

- Select a surface to generate a preview of a pin support.

- Select the support to edit it.

-

Use the icons in the microdialog to define the shape of the support. Options

are: cross-shaped, plus-shaped, square, and circle.

- Enter a Diameter.

- Click Generate.

Partition Supports

Split a support and move the partitions so they are in contact with the printing bed.

tool on the microdialog to drag the partitioned

sections away from the part so they are in contact with the printing bed.

tool on the microdialog to drag the partitioned

sections away from the part so they are in contact with the printing bed.