- Heat Input (Qin)

- Hot Fluid Delta.T

- Cold Fluid Delta.T

- Effectiveness

- Effectiveness vs Flow_Rate_Cold vs

Flow_Rate_Hot

Effectiveness is obtained from User Defined

Input for Effectiveness as function Flow_Rate_Cold and

Flow_Rate_Hot.

- Effectiveness vs NTU vs Heat Capacity Ratio

Effectiveness is

obtained from User Defined Input for Effectiveness as function NTU and

Heat Capacity Ratio.

UA is calculated from Constant user input or from

curve specified for Nusselt Number as function of Reynolds Number Cold

and Reynolds Number Hot

- Nusselt Number vs RE_Cold vs RE_Hot

Nusselt Number is

obtained from User Defined Input for Nusselt Number as function of

Reynolds Number Cold and Reynolds Number Hot

- Constant hA Coefficient value

NTU Effectiveness Methods:

- Cross Flow Unmixed

- Counter Flow

- Parallel Flow

- Cross Flow Both Side Mixed

- Cross Flow One Side Mixed

Cmin is mixed:

Cmax is mixed:

- Hs Parameter Methods (Constant and vs Hot and Cold

Flowrates)

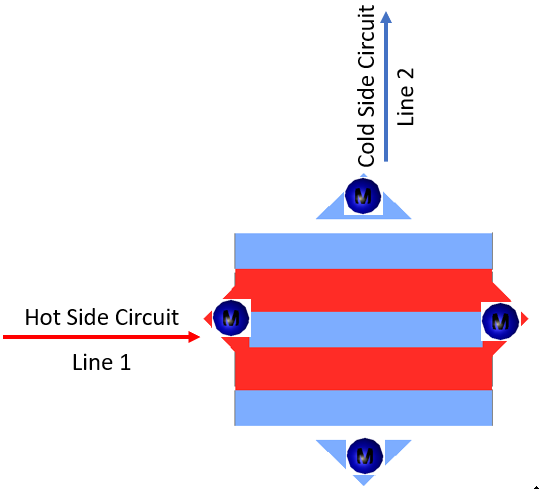

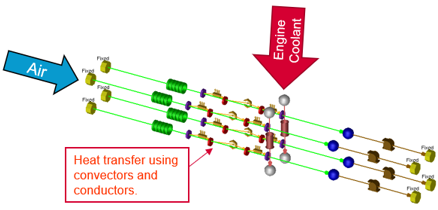

The Hs parameter is typically used to describe

radiators where the hot side is a liquid coolant, and the cold side is

air.

A heat exchanger effectiveness can be calculated using

the Hs parameter.

Q is found using the effectiveness Qmax. The Q is

applied to the fluid streams to get the exit temperatures.