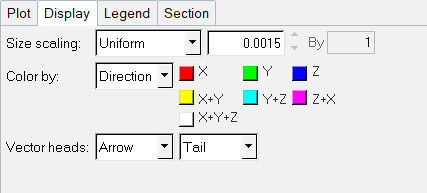

ACU-T: 3200 Radiation Heat Transfer in a Simple Headlamp using the Enclosure Radiation Model

Prerequisites

This tutorial introduces you to setting up a radiation heat transfer problem using the Enclosure radiation model in HyperMesh and solving using AcuSolve. Prior to starting this tutorial, you should have already run through the introductory HyperWorks tutorial, ACU-T: 1000 HyperWorks UI Introduction, and have a basic understanding of HyperMesh, AcuSolve, and HyperView. To run this simulation, you will need access to a licensed version of HyperMesh and AcuSolve.

Prior to running through this tutorial, copy HyperMesh_tutorial_inputs.zip from <Altair_installation_directory>\hwcfdsolvers\acusolve\win64\model_files\tutorials\AcuSolve to a local directory. Extract ACU-T3200_HeadlampEnclosure.hm from HyperMesh_tutorial_inputs.zip.

Since the HyperMesh database (.hm file) contains meshed geometry, this tutorial does not include steps related to geometry import and mesh generation.

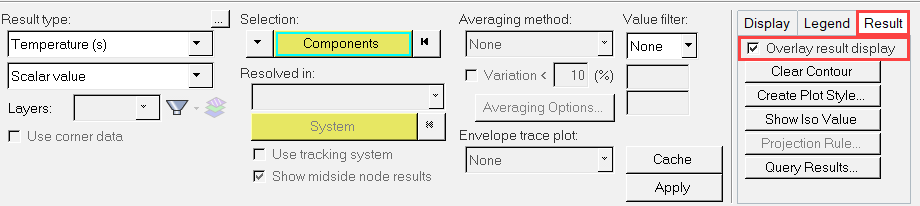

Problem Description

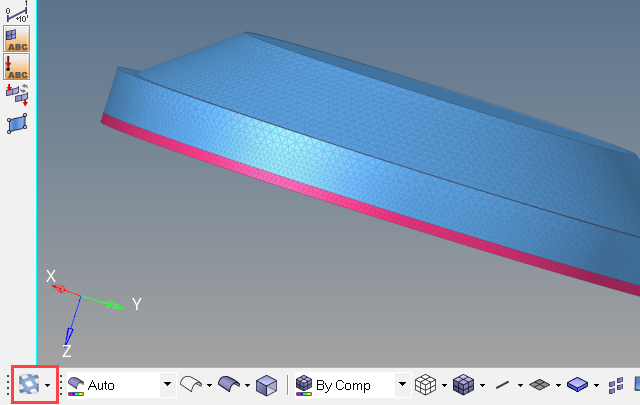

Figure 1.

Figure 2.

Open the HyperMesh Model Database

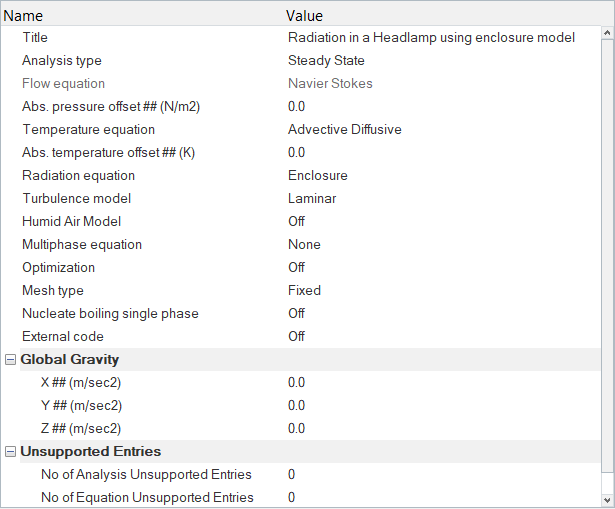

Set the General Simulation Parameters

Set the Analysis Parameters

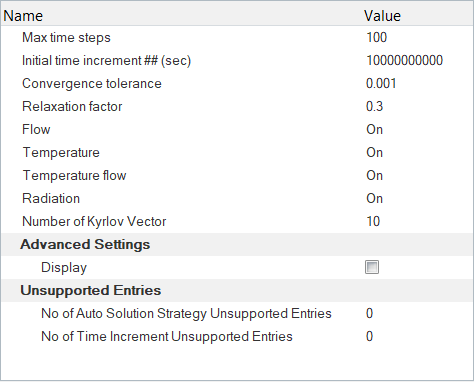

Specify the Solver Settings

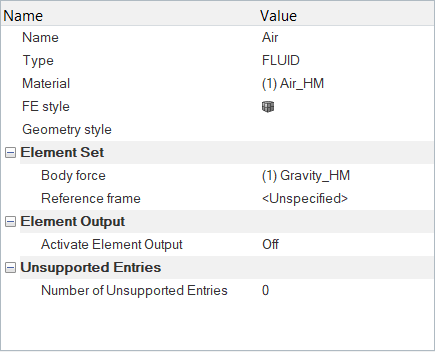

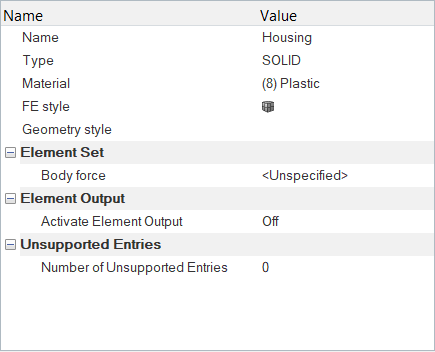

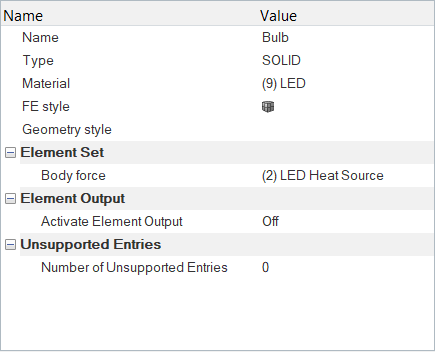

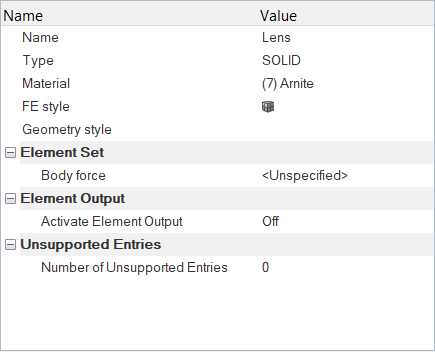

Define the Material Models and the Body Force

Define the Material Models

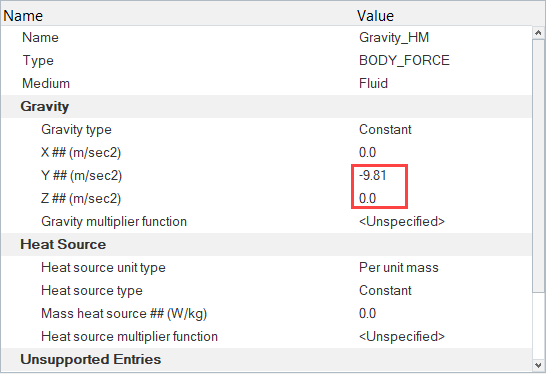

Define the Body Force

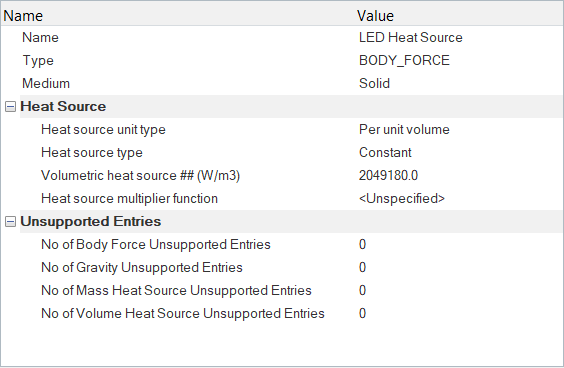

Define the Heat Source

Set the Boundary Conditions

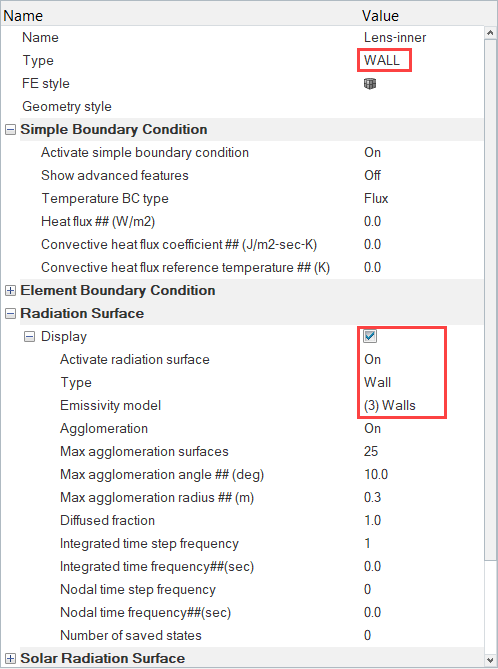

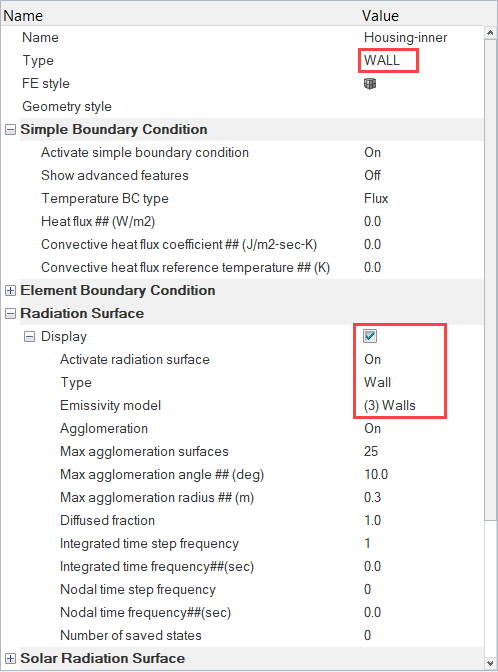

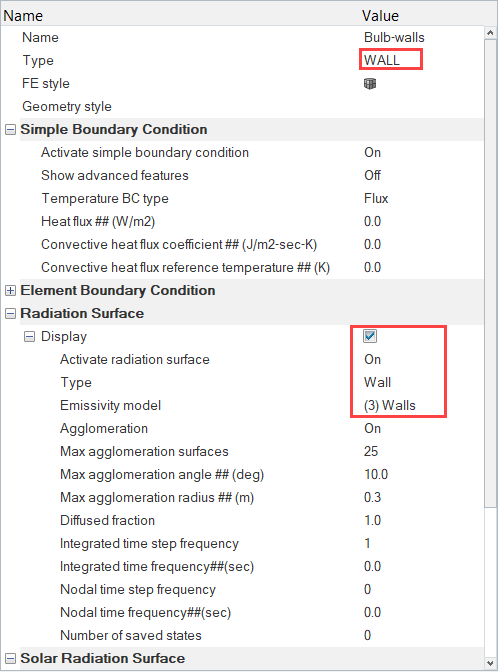

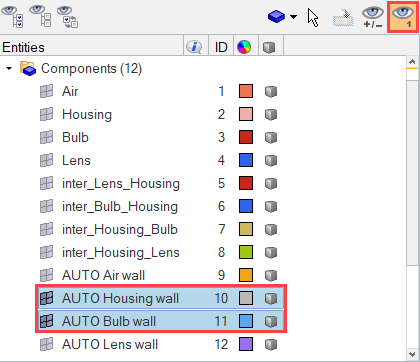

Create the Emissivity Model

- In the Solver Browser, right-click on 07.Emissivity_Model and select Create.

- In the Entity Editor, name it Walls.

- Set the Emissivity to 0.7.

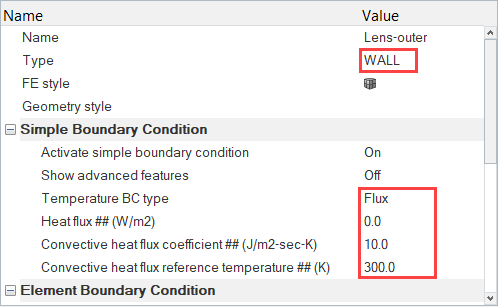

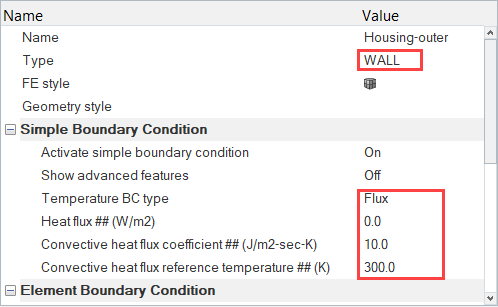

Set the Boundary Conditions

Compute the Solution

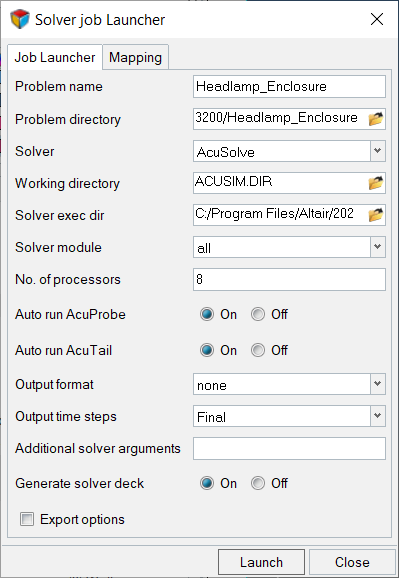

Run AcuSolve

In this step, you will launch AcuSolve to compute a solution for this case.

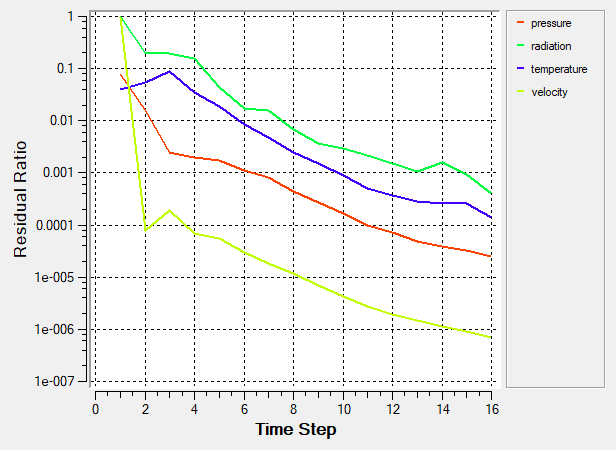

Monitor the Solution with AcuProbe

While AcuSolve is running, you can monitor the progress of the solution using AcuProbe and plot the values of residual ratios, solution ratios, and variables like temperature, heat flux, etc. Once the solver run has started, the AcuTail and AcuProbe windows should be launched automatically.

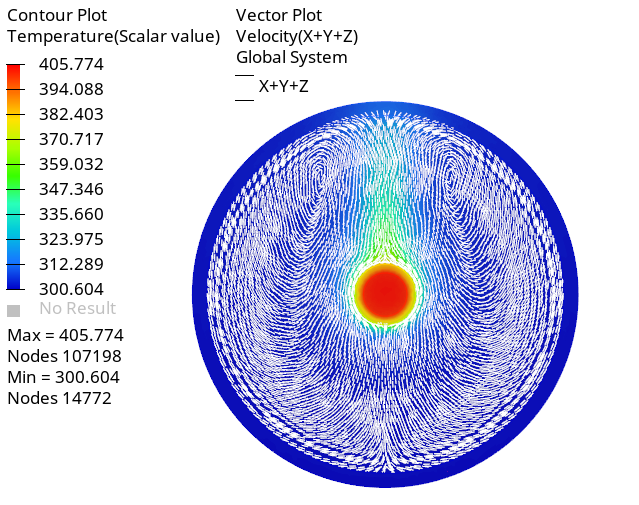

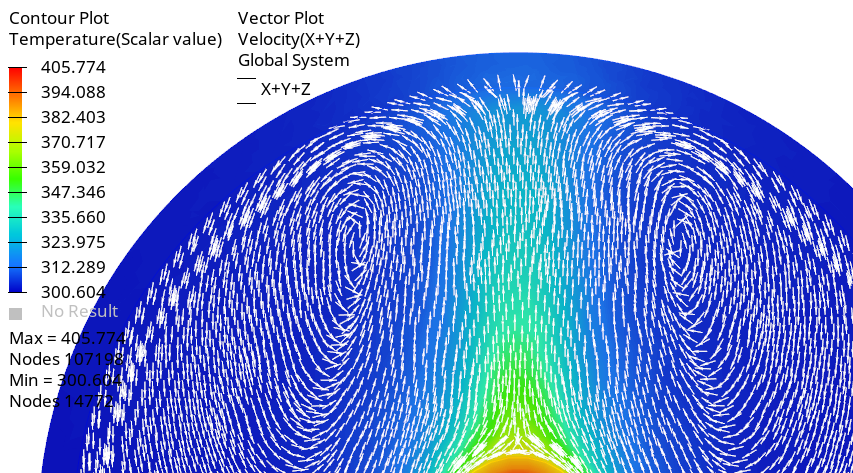

Post-Process the Results with HyperView

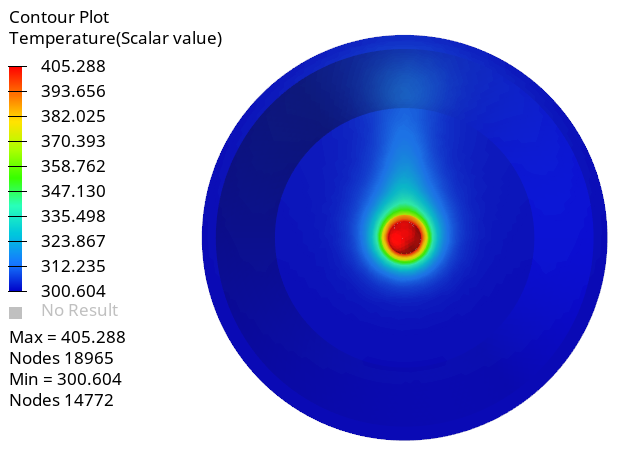

In this step, you will visualize the results using HyperView. While doing so, you will create contour plots of temperature and velocity magnitude on a section cut and also create a plot of velocity vectors. Once the solver run is complete, close the AcuProbe and AcuTail windows. In the HyperMesh Desktop window, close the AcuSolve Control tab and save the model.

Switch to the HyperView Interface and Load the AcuSolve Model and Results

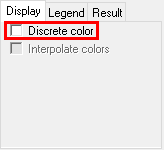

Create a Contour Plot of Temperature

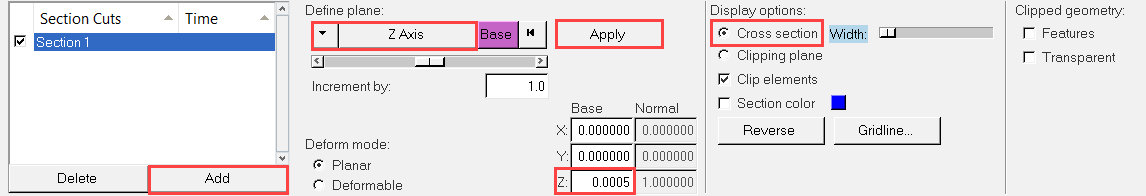

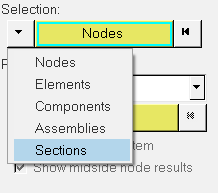

Display Temperature Contours and Velocity Vectors on a Section Cut

In this step, you will create a section cut on the mid-z plane and then display the temperature and velocity vectors on that cross section.

Summary

In this tutorial, you learned how to set up and solve a radiation heat transfer problem in a headlamp using the enclosure radiation model in AcuSolve. You started by importing the HyperMesh database with the mesh and basic model organization and then set up the simulation parameters and boundary conditions. Once the solution was computed, you processed the results using HyperView, where you created contour plots of temperature and velocity vectors in the fluid domain.

on the Standard Views toolbar.

on the Standard Views toolbar.