Manage Subsystem Configurations

Group unique subsystems together into subsystem sets and organize both subsystems and subsystem sets into configurations.

The typical model assembly workflow is to set each subsystem up as an include file. Each configuration of subsystems is then managed through a separate header deck referencing the appropriate include files. This is an efficient way of building a model since updates can be performed per subsystem rather than per system model. However, this requires multiple header decks to be updated, strict management of ID ranges for each include, as well as control over the connectivity between includes.

Subsystems support and enhance this workflow since each subsystem can be written out as an include file. Additionally, all subsystems and subsystem configurations are stored in a single .hm file. When a particular subsystem is updated, multiple header decks can be written out from a single file using configurations rather than editing multiple header decks.

ID management is covered through ID Manager. Connectivity between subsystems is managed through Subsystem Attachments and Connectors. This ensures that connectivity is maintained to the other subsystems even if one subsystem is worked on independently.

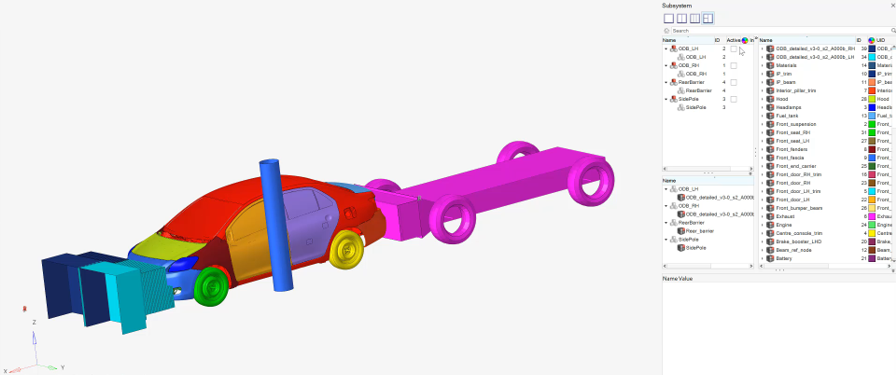

Figure 1.