Show Analysis Results

Analyze the results to minimize defects and prevent problems.

Results must be available in the Run History before viewing.

Result Types

Results are available for filling, packing, cooling, and warpage analysis stages.

Filling Results

| Option | Description |

|---|---|

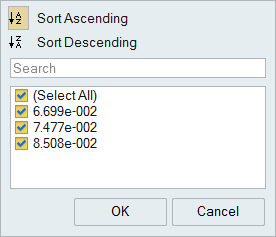

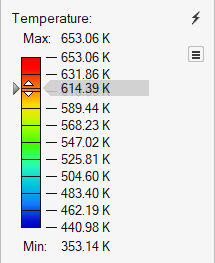

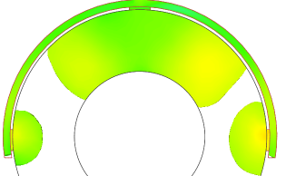

| Temperature | Review the temperature evolution of the fluid entering the

mold cavity. Check regions for excessive heating or cooling.

Determine the appropriate fill speed for uniform temperature

distribution. |

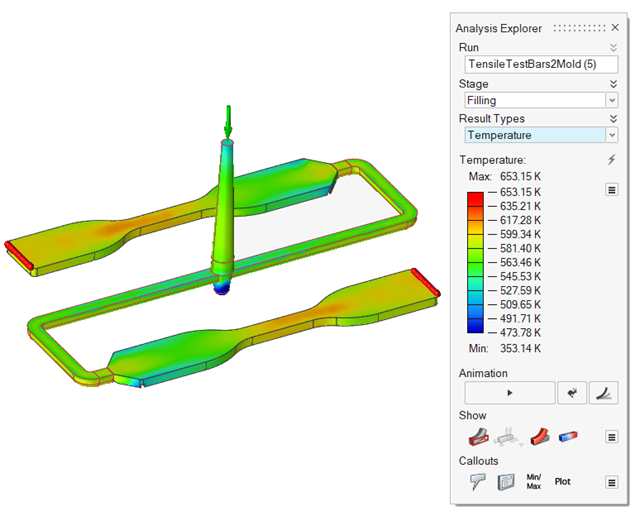

| Flow Front Temperature | Review the temperature at the time of filling. |

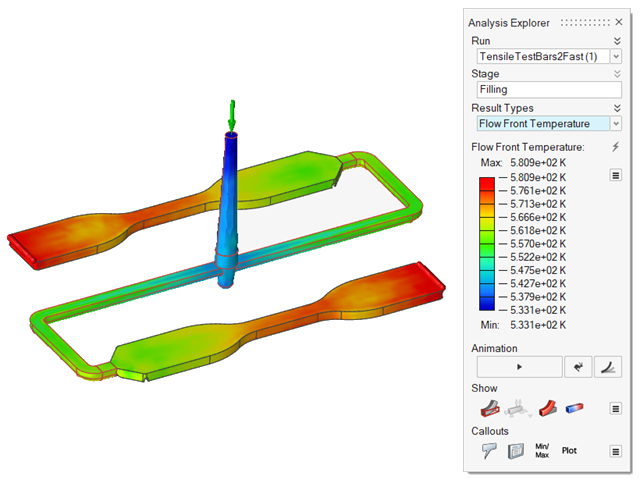

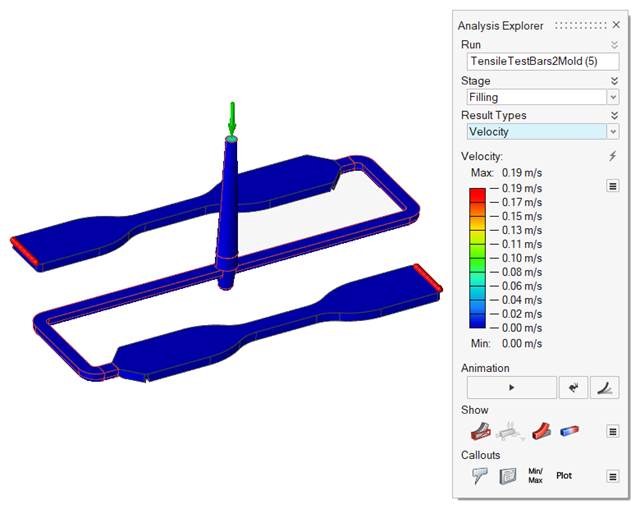

| Velocity | Examine the velocity vectors evolution during the filling of

the mold. Click the Show and

Options buttons to change to velocity

contour fill animation. |

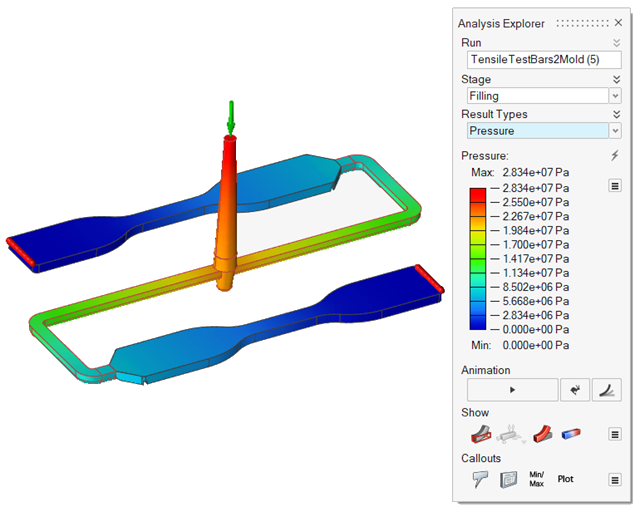

| Pressure | Review pressures inside the mold cavity produced during the

filling stage. |

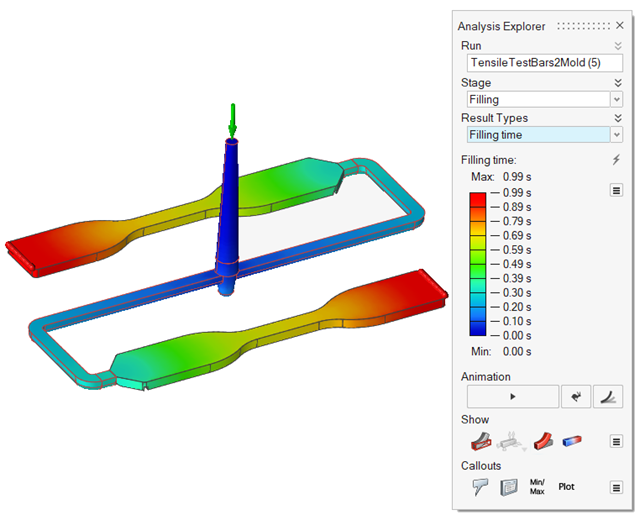

| Filling Time | Review the time it takes the material to reach different

areas within the part. The filling results can help you

determine the best way to fill the part and detect patterns that

indicate the potential for incomplete filling, unbalanced flow,

weld lines and air pockets. |

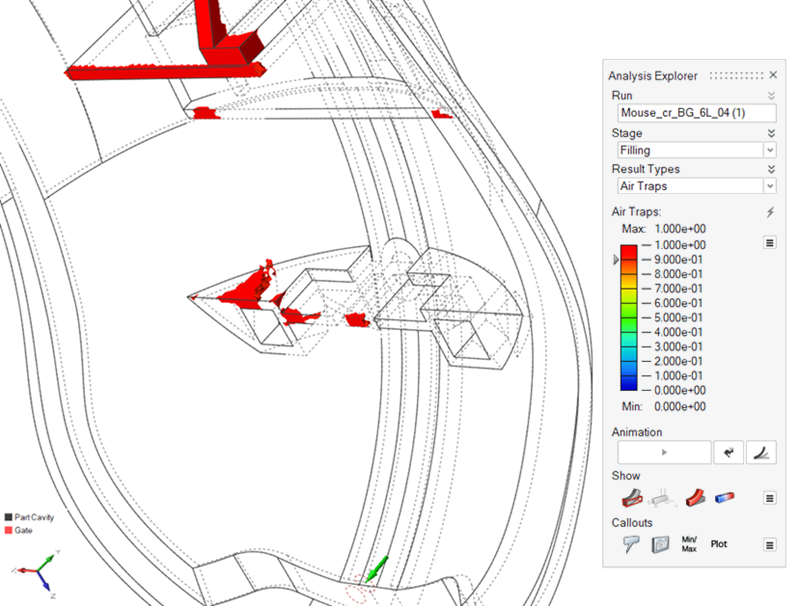

| Air Traps | Locate air trapped in the mold during filling due to

different flow patterns. Consider adjusting the venting in the

simulation. |

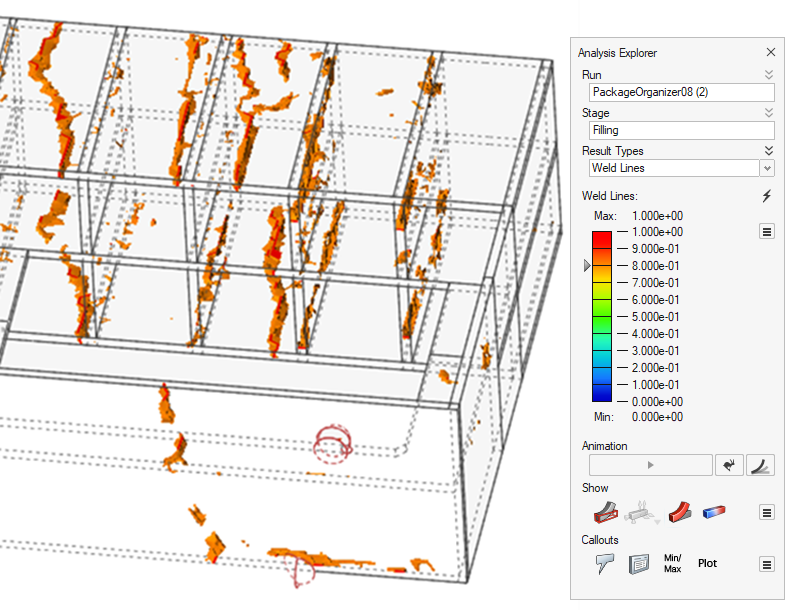

| Weld Lines | Locate regions during filling where two flow fronts meet.

Such regions may cause structural and cosmetic issues. |

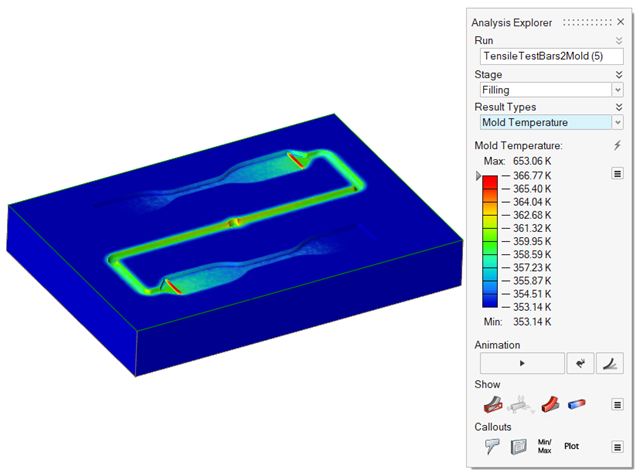

| Mold Temperature | Review temperature variances in the mold. |

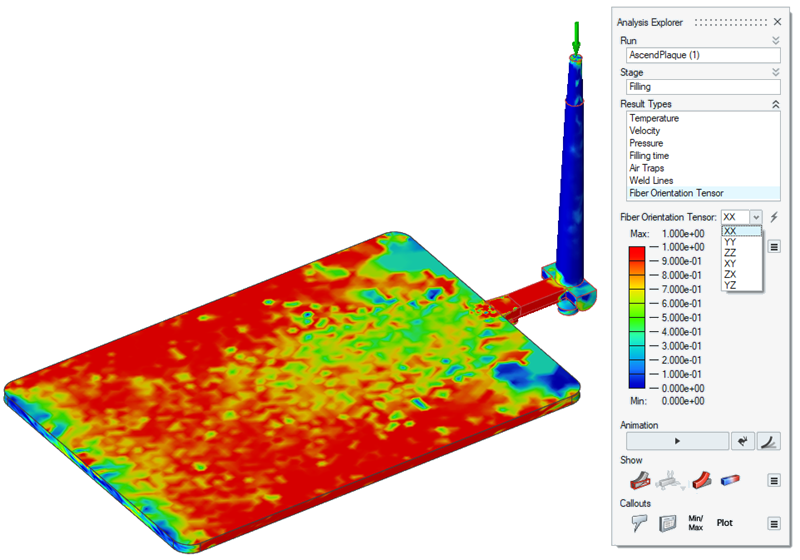

| Fiber Orientation Tensor | Review diagonal and cross products results for the tensors.

The result predicts the fiber orientation tensor for short fiber

reinforced polymers.

|

Packing Results

| Option | Description |

|---|---|

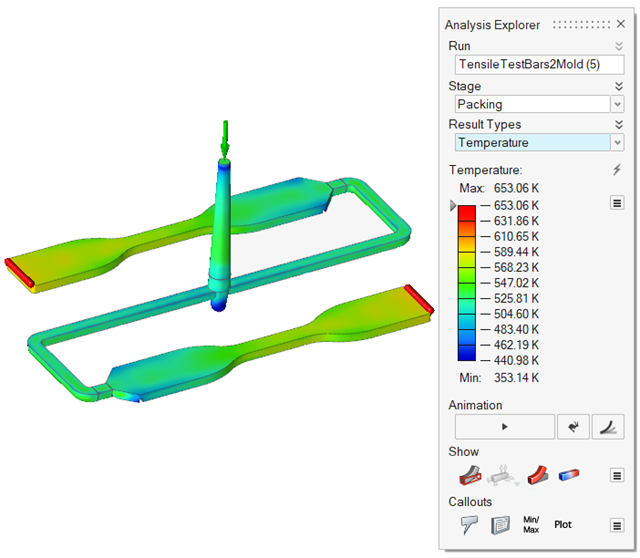

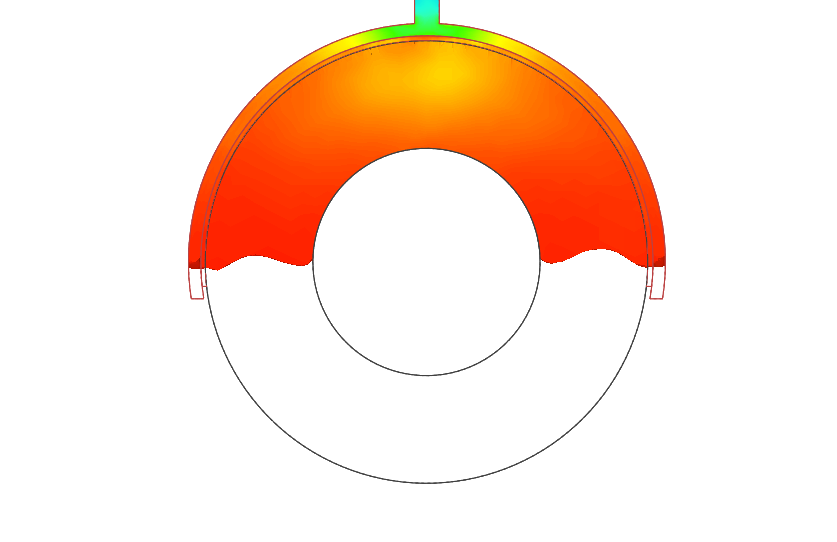

| Temperature | Review temperatures during the packing phase. The temperature

will decrease due to the temperature loss across the mold

walls. |

| Velocity | Examine velocity during the packing phase. Velocities will

decrease until the fluid stops flowing. |

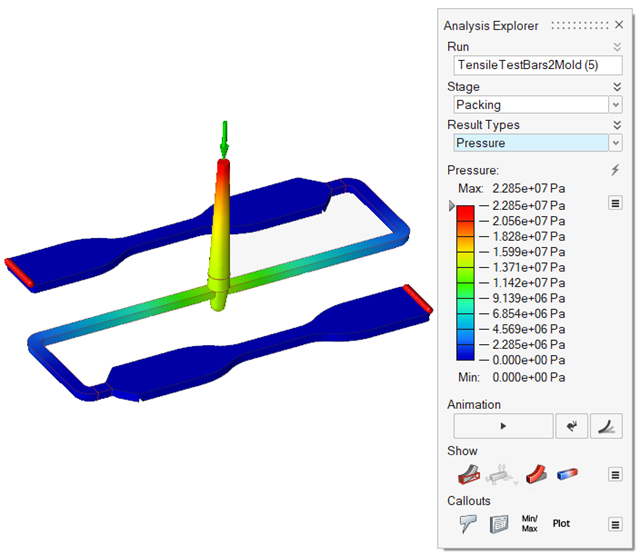

| Pressure | Consider pressures during the packing phase. These results

are useful to know points where the pressure is less than 0 to

detect areas prone to suffer a sink mark defect. |

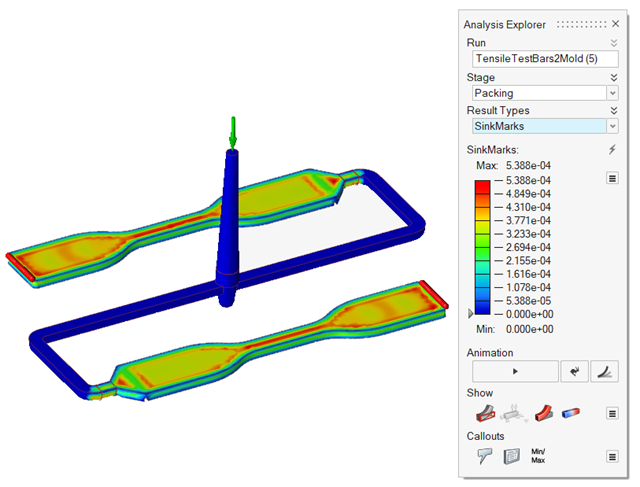

| Sink Marks | Detect surface depressions, usually in the thicker sections

of the model, caused by shrinkage during the packing

stage. |

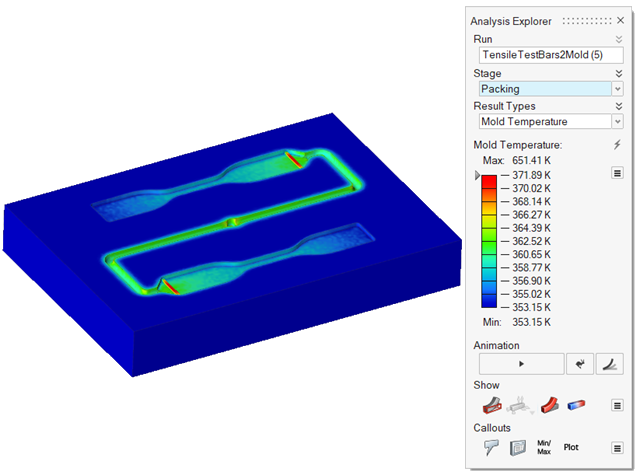

| Mold Temperature | Review temperature variances in the mold. |

Cooling Results

| Option | Description |

|---|---|

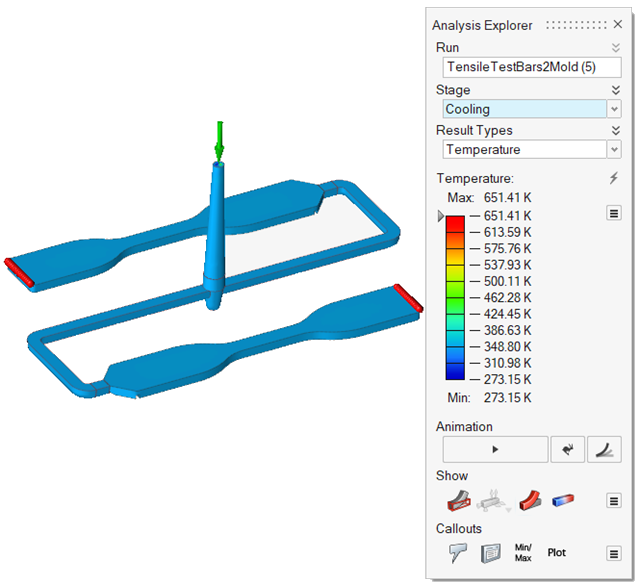

| Temperature | Examine the temperature evolution once the mold is totally

filled. You can determine the final temperature at which to stop

the cooling phase. |

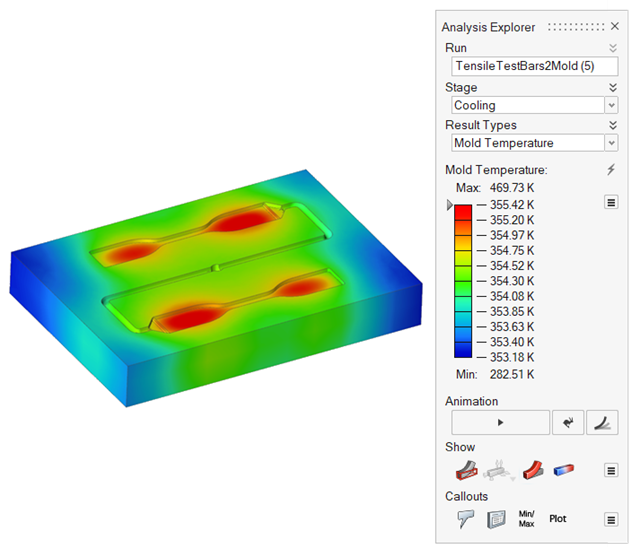

| Mold Temperature | Review temperature variances in the mold. |

Warpage Results

| Option | Description |

|---|---|

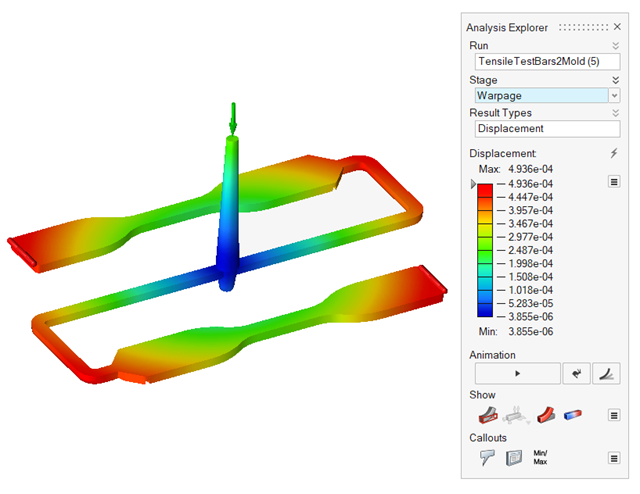

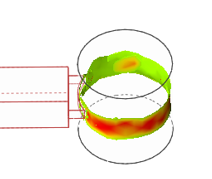

| Displacement | Due to non-uniform cooling, the molded part can warp, which

can cause the part to fold, bend, twist or bow. The displacement

contour displays how the part is warping so that you can make

the appropriate corrective measures to the cooling rate, cooling

channel design, or process data. |

View Molding Defects

Fix issues with air traps, weld surfaces, and sink marks.

Add Callouts to the Results

Call out and review values for a selected result type at points of interest on your model using the callout icons in the Analysis Explorer.

After running an analysis, click the Show Analysis Results icon. The Analysis Explorer appears to the right of the model.

or

or  to select

to select