Radioss ACM (Shell Gap Contact and Coating)

The Radioss acm (shell gap contact and coating) realization creates hexa clusters between shell components. Contacts get defined between the shell components and the appropriate hexa nodes. A heat affected zone for the shells from ultra high strength steel material is also created.

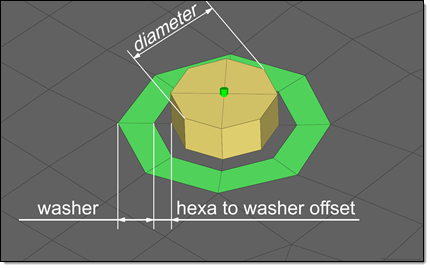

Figure 1. Heat Affected Zone Dimensions

Organization and Definition of ACM (Shell Gap Contact and Coating)

- For each connected link the contact /inter/TYPE2/ gets created and is named

TYPE2_CONTACT_PID_<link ID>. The following sets are created and referenced.

- MAINPART_SET_PID_<link ID>: In this set, which is referenced as the main by the above mentioned contact, the link entities like the component get organized.

- SLAVENODE_SET_PID_<link ID>: In this set, which is referenced as the secondary by the above mentioned contact, the hexa nodes projecting onto the main entities get organized.

- For each link combination the hexa clusters are organized into separate components and

named RAD_SOLID_SPOTWELD_PID_<link1 ID>_<link2 ID>. All components are assigned

the following material and property:

- RAD_SOLID_SPOTWELD_DEFAULT_MAT. This material is defined as /MAT/LAW59/.

- RAD_SOLID_SPOTWELD_DEFAULT_PROP. This property is defined as /PROP/CONNECT/.

The default values are read from uhss_washersolid_matprop.rad in the installation.

- The heat affected zone elements (washer) are organized into one separate component for

each link from the ultra high strength steel material and named RAD_WASHER_PID_<link

ID>. All components are assigned the following material and property:

- RAD_WASHER_MAT. This material is defined as /MAT/PLAS_JOHNS/.

- RAD_WASHER_PROP. This property is defined as

/PROP/SHELL/.

The material and property values are read from uhss_washersolid_matprop.rad in the installation.

Defining Materials for Heat Affected Zone Treatment

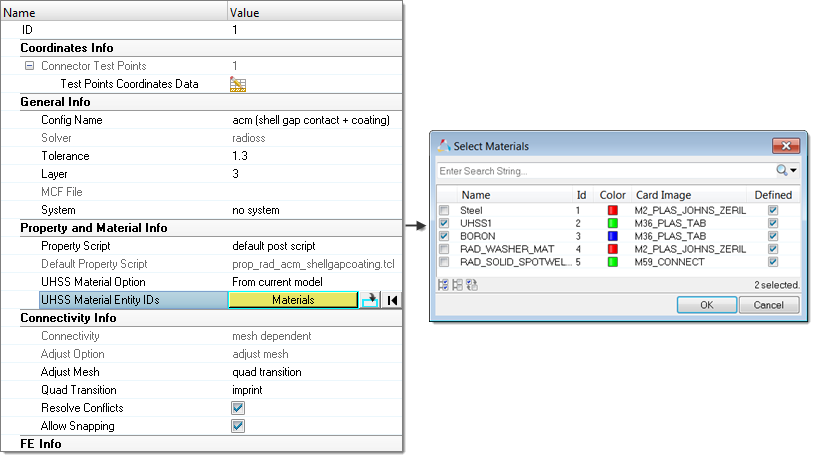

You must specify which materials are considered as ultra high strength materials. When defining an acm (shell gap contact and coating) connector, the UHSS Material Option can be selected for individual connectors using the Connector Entity Editor.

- From current model

- Select an existing material from the current model.

Figure 2. From Current Model - From search file (default)

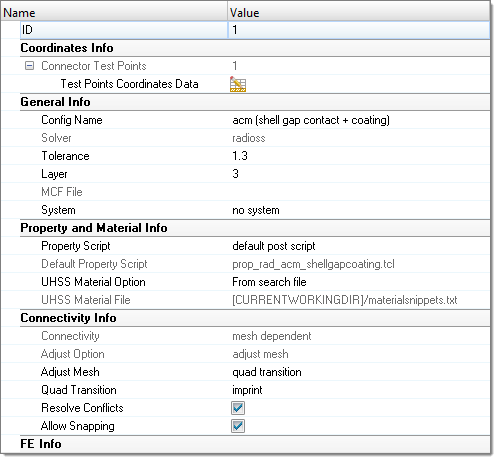

- For acm (shell gap contact and coating) realizations, the material search file name

is materialsnippets.txt. HyperMesh

searches for this file in the following locations and in the following order:

- Installation: [hm_scripts_dir]/connectors/materialsnippets.txt

- User directory: [USER_HOME]/materialsnippets.txt

- HyperWorks Configuration Path folder: [HW_CONFIG_PATH]/materialsnippets.txt

- Current working folder:

[CURRENTWORKINGDIR]/materialsnippets.txtv

Figure 3. From Search File

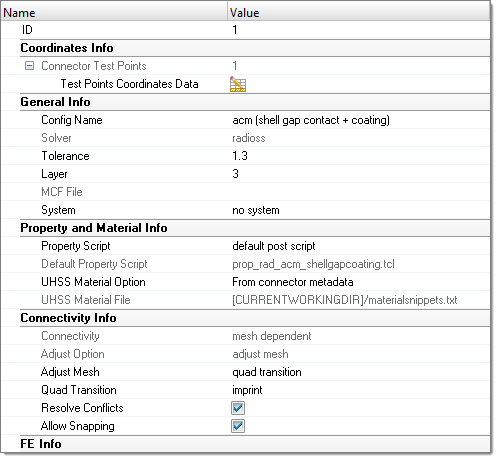

- From connector metadata

- Once a connector is realized with the UHSS Material Option “From search file”, the

folder name is written as metadata to the connector in a relative manner to allow the

exact same rerealization in a different work environment as long as the same

materialsnippets.txt files are saved in according folders.

Figure 4. From Connector Metadata