Use the Dummy Positioning Process Manager

The Dummy Positioning Process Manager tool guides you through the workflow of positioning a dummy in a seat.

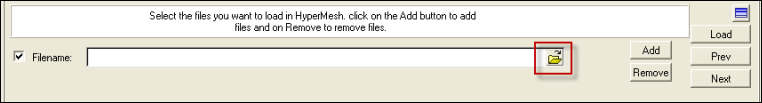

The recommended steps include an interactive positioning process, during which you specify the H-point position of the dummy, as well as the rotation angles of each joint, such as arm and leg. When finished with this phase, you will be able to store a transformation file which can later be applied on the dummy only in the next phase, the automatic positioning process. In this phase, you can choose to export only the nodes, which creates a copy of the original dummy file with the updated nodes. The rest of the dummy input file remains unchanged with this option.

In the Process Manager tab, you will see the workflow process. As you complete the positioning process, the boxes will become filled with green check marks to indicate the completion of each step.

Use the H-Point subpanel to position the dummy to the H-Point, or rotate the entire dummy about the H-Point. For positioning, you can specify either the coordinates or a node for the new H-Point. For rotating, specify the axis of rotation and the angle. In either case, picking any component in the dummy is sufficient.