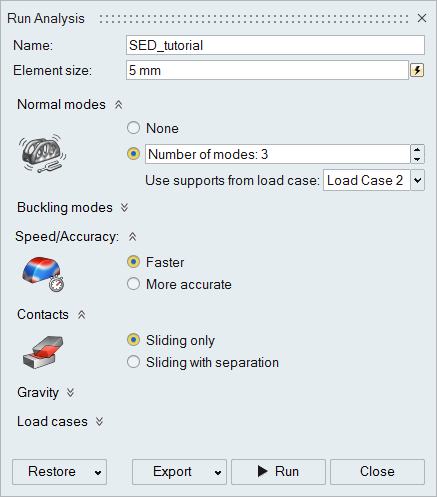

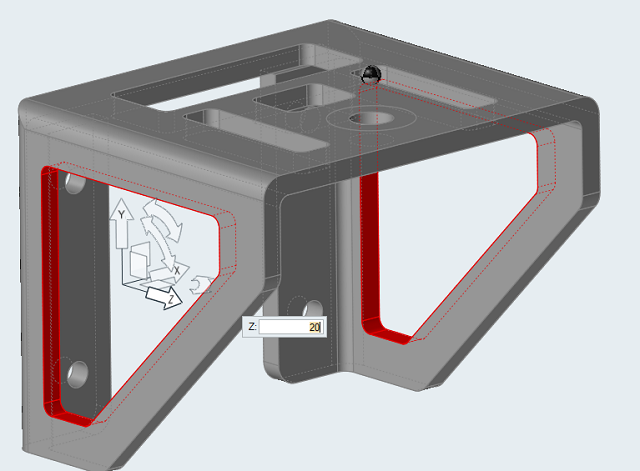

Tutorial: Strain Energy Density Analysis

Run a normal modes analysis and examine the strain energy density results.

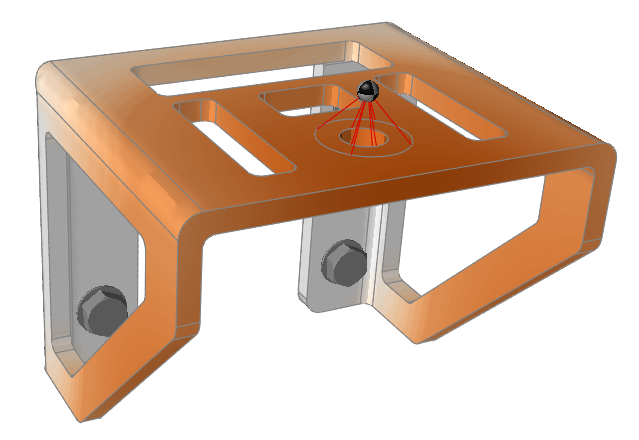

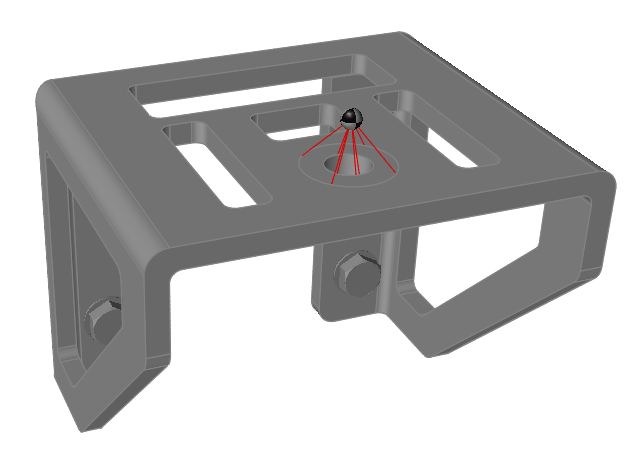

Run a modal analysis and use the strain energy density results to improve the design of a simple bracket that supports a mass.

In this lesson, you will:

- Run a normal modes analysis on a simple bracket supporting a mass

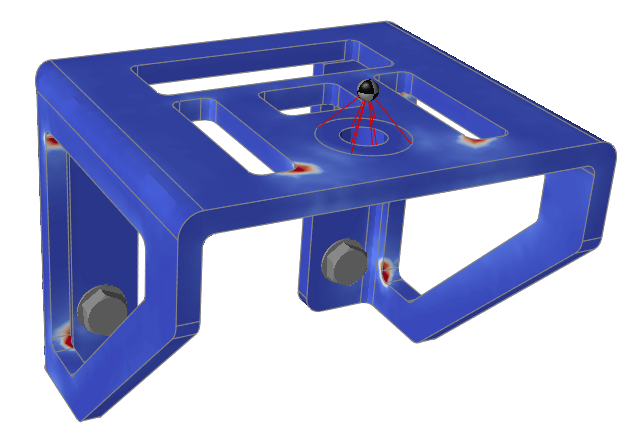

- Examine the strain energy density results

- Change the design of the bracket (without adding any mass) based on these results

- Compare the designs

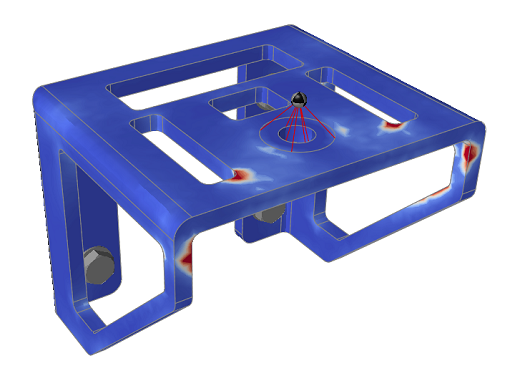

Figure 1. Strain Energy Density Analysis Results

Figure 1. Strain Energy Density Analysis ResultsThe purpose of the tutorial is to demonstrate the following principles:

- When a structure deforms, different regions strain by different amounts. The sum of the energy in the structure due to the deformation is called the strain energy.

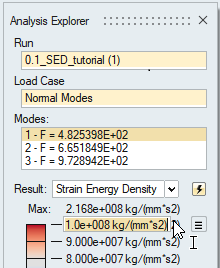

- Eigenvalues are normalized when a modal analysis is performed. The strain energy density results are used to determine which areas of the structure are under the greatest strain and contribute most to the stiffness.

- Targeting areas of high strain energy density for design changes is a common method to increase the natural frequencies in a modal analysis.

Examine the Model and Run a Modal Analysis

Review the Strain Energy Density Results

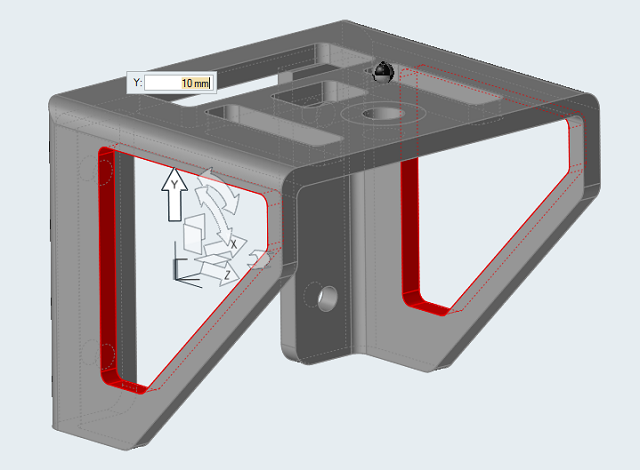

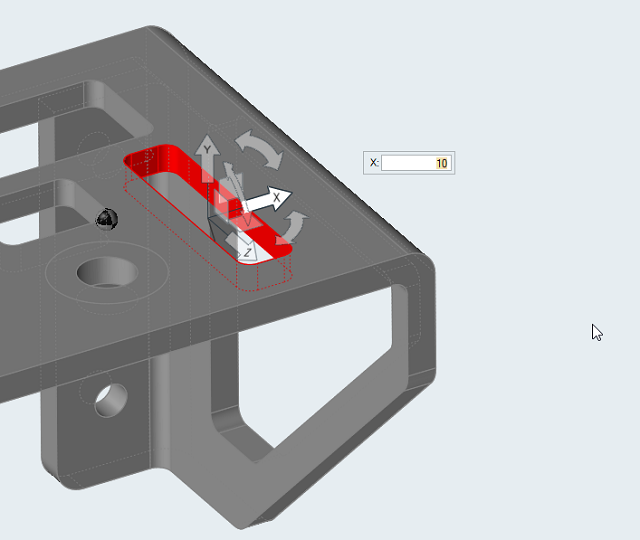

Add Material to the High Strain Regions

In summary, targeting areas of high strain energy density is a powerful approach for increasing the stiffness of structures. In this tutorial the first mode was increased significantly with no material added.

on

the

on

the