In some cases, you may want to change the natural frequency of an object, so as to

avoid resonance with other parts in your design. Use frequency constraints to control the

frequency at which an optimized part vibrates.

-

On the Structures ribbon, click Run Optimization

on the

Optimize icon.

on the

Optimize icon.

-

Select the optimization Type.

-

Select Maximize Stiffness or Maximize

Frequency as the optimization objective.

-

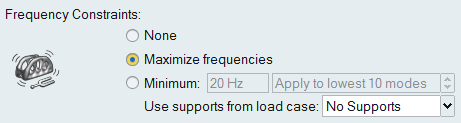

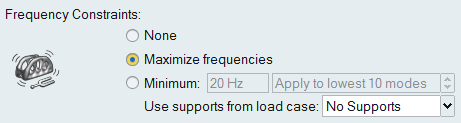

Select an option for Frequency Constraints.

| Option |

Description |

|---|

| Maximize Frequencies |

Select Maximize frequencies. (If you selected

Maximize Frequency as the optimization objective, this step is not

necessary.) |

| Minimum |

Select Minimum and enter the lowest frequency

you want to allow in the text field. Use the arrows in the scroll menu

to select the number of modes that you must exceed the minimum

frequency.

|

-

If you want to include supports in the calculation, select the load case that

includes the supports you want to use from the Use Supports from Load

Case pull-down menu. You can also select No

Supports.

-

Define additional optimization constraints and options as desired.

-

Click Run to start the optimization.

-

When complete, double-click the name of the run to view the results.

| Option |

Description |

|---|

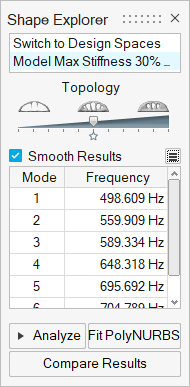

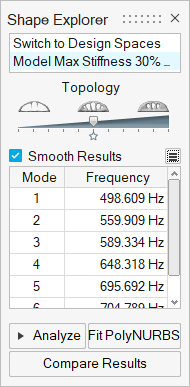

| Maximize Frequencies |

The Shape Explorer displays the frequencies

for the first six modes.

|

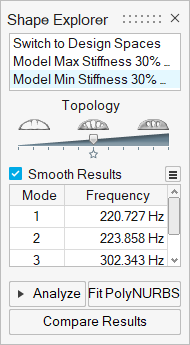

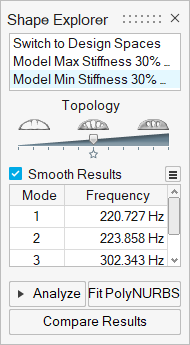

| Minimum Frequency Constraint |

The Shape Explorer displays the frequencies

for the modes that you selected.

|

Tip:

- When maximizing stiffness, you may choose to either maximize

frequencies or set a specific minimum frequency. If you choose to

maximize frequencies, Inspire will

automatically maximize both the stiffness and frequency of the

model, and the lowest natural frequency will be displayed in the

Shape Explorer window. If the resulting frequency is not high enough

to meet your constraint, you may need to assign a stiffer material

or modify your mass target for the optimized shape (if running

topology optimization).

- When minimizing mass, you may enter a specific minimum frequency and

specify how many of the lowest modes must exceed that frequency. If

Inspire is unable to achieve the

specified frequency for the lowest modes, this will be flagged in

the Shape Explorer.

- When maximizing frequency as the optimization objective, you cannot

set a minimum frequency, but you can choose whether to include

supports from a specific load case.

What If I'm Not Achieving My Frequency Constraint?

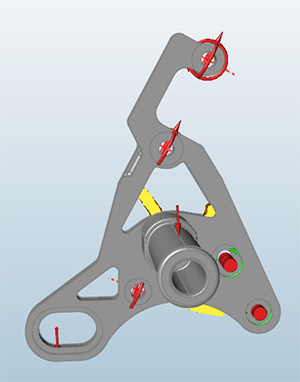

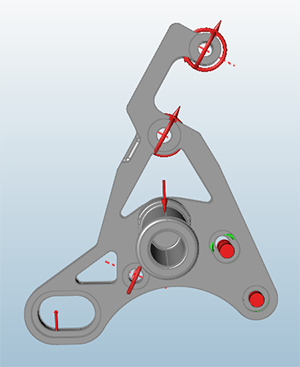

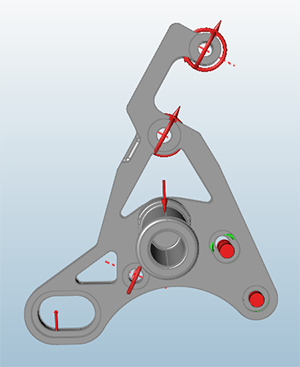

If your optimized shape is not achieving your desired frequency constraint, you may

need to add material to your part if running a topology optimization. In the example

below, the final part as designed was not achieving the required minimum frequency

of 500 Hz.

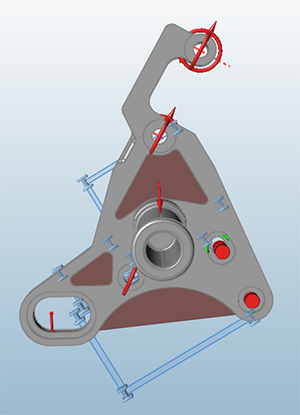

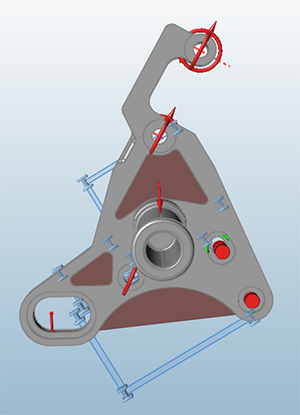

As a result, it was necessary to add three design spaces and apply an extrusion shape

control so that additional material could be added to meet the frequency

constraint.

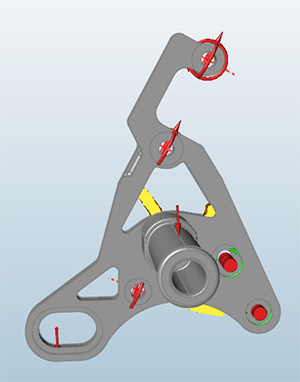

Then an optimization was run, with the objective to minimize mass. Only a frequency

constraint (no stress or displacement constraints) were applied. The image below

shows the resulting shape, with the additional material needed to meet the frequency

constraint displayed in yellow.