RD-E: 4602 Euler Formulation

The purpose of this example is to show how to simulate the cylinder expansion test and compare the simulation result to experimental data.

Detonation is initiated at the bottom of the explosive. Radial expansion of the cylinder is measured and compared to experimental data.

Options and Keywords Used

- Euler formulation

- Multi-Material Solid, Liquid, and Gas material law (/MAT/LAW51 (MULTIMAT))

- Brick elements

- Axisymmetrical analysis (/ANALY)

- Solid property (/PROP/TYPE14 (SOLID))

- Boundary condition (/BCS)

- Detonation plan (/DFS/DETPLAN)

Due to the symmetries of the model, a quarter of the cylinder is modeled. Boundary conditions are set on the yOz plan at x = 0 (Tx = 0) and on the xOz plan at y = 0 (Ty = 0) to simulate the symmetry.

A planar detonation wave is defined at the bottom of the cylinder. A scale factor of 0.5 (on time step for all elements) is used for this type of application.

- Isolid is set to 0 for TNT and copper solid properties.

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/PROP/SOLID/2

copper

# Isolid Ismstr Icpre Itetra10 Inpts Itetra4 Iframe dn

0 0 0 0 0 0 0 0

# q_a q_b h LAMBDA_V MU_V

1.1 .05 0 0 0

# dt_min istrain IHKT

0 0 0

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/PROP/SOLID/1

TNT

# Isolid Ismstr Icpre Itetra10 Inpts Itetra4 Iframe dn

0 0 0 0 0 0 0 0

# q_a q_b h LAMBDA_V MU_V

1.1 .05 0 0 0

# dt_min istrain IHKT

0 0 0

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|Input Files

- Cylinder Test

- <install_directory>/hwsolvers/demos/radioss/example/46_TNT_Cylinder_Expansion_Test/Euler/*

Model Description

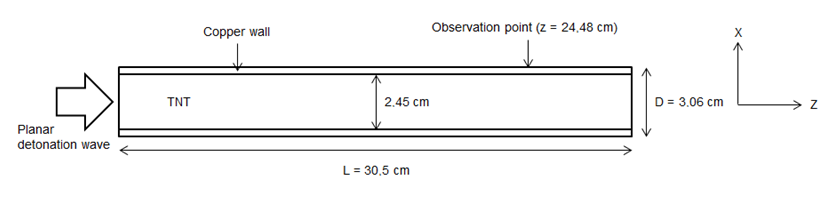

A OFHC copper cylinder (1.53cm diameter, 0.26cm thickness, 30.5cm height) is filled with an explosive (TNT). Detonation is initiated at the bottom of the explosive. Radial expansion is measured at a length of 8*D cm. With an Euler formulation, the air has to be modeled to measure radial expansion.

Figure 1. Problem Description for Cylinder Test

Units: cm, s, g, Mbar

- Material Properties

- Initial density

- 8.96

- Initial pressure C0mat1

- 1e-6

- Hydrodynamic coefficients

- C1mat1= 1.38

- Elastic shear modulus G1mat1

- 0.519

- Yield stress amat1

- 0.9e-3

- Plastic yield factor bmat1

- 0.292e-2

- Plastic yield exponent nmat1

- 0.31

- Plastic strain rate factor cmat1

- 0.025

- Plastic reference strain rate

- 1e-6

- Thermal exponent mmat1

- 1.09

- Specific heat Rhocvmat1

- 3.461e-5

- Tmelt

- 1656

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/MAT/LAW51/1

Copper

# Iform

10

# P_ext NU Nu_Vol

0 0 0

# ALPHA0_mat1 RHO0_mat1 E0_mat1 Pmin_mat1 C0_mat1

1 8.96 0 0 1E-6

# C1_mat1 C2_mat1 C3_mat1 C4_mat1 C5_mat1

1.38 1.372 0 .87 .87

# G1_mat1 a_mat1 b_mat1 n_mat1

.519 9E-4 .00292 .31

# c_mat1 EPSILON_DOT0_mat1

.025 1E-6

# m_mat1 T0_mat1 Tmelt_mat1 Tlim_mat1 Rhocv_mat1

1.09 0 1656 0 3.461E-5

# Epspmax_mat1 sigma_max_mat1 KA_mat1 KB_mat1

0 0 0 0

# ALPHA0_mat2 RHO0_mat2 E0_mat2 Pmin_mat2 C0_mat2

0 .0012 2.5E-6 -1E-20 0

# C1_mat2 C2_mat2 C3_mat2 C4_mat2 C5_mat2

0 0 0 .4 .4

# G1_mat2 a_mat2 b_mat2 n_mat2

0 0 0 0

# c_mat2 EPSILON_DOT0_mat2

0 0

# m_mat2 T0_mat2 Tmelt_mat2 Tlim_mat2 Rhocv_mat2

0 0 0 0 0

# Epspmax_mat2 sigma_max_mat2 KA_mat2 KB_mat2

0 0 0 0

# ALPHA0_mat3 RHO0_mat3 E0_mat3 Pmin_mat3 C0_mat3

0 0 0 0 0

# C1_mat3 C2_mat3 C3_mat3 C4_mat3 C5_mat3

0 0 0 0 0

# G1_mat3 a_mat3 b_mat3 n_mat3

0 0 0 0

# c_mat3 EPSILON_DOT0_mat3

0 0

# m_mat3 T0_mat3 Tmelt_mat3 Tlim_mat3 Rhocv_mat3

0 0 0 0 0

# Epspmax_mat3 sigma_max_mat3 KA_mat3 KB_mat3

0 0 0 0

# ALPHA0_mat4 RHO0_mat4 E0_mat4 Pmin_mat4 C0_mat4

0 1.63 .07 -1E-20 1E-6

# A B R1 R2 W

3.712 .0323 4.15 .95 .3

# D PCJ C1_mat4

.693 .21 .036

/EULER/MAT/1

# Modif. factor.

0

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|- Material Properties

- Initial density

- 1.63

- Explosive cavitation pressure Pminmat4

- -1e-20

- Initial explosive pressure C0mat4

- 1e-6

- Explosive coefficient B1

- 3.712

- Explosive coefficient B2

- 0.0323

- Explosive coefficient R1

- 4.15

- Explosive coefficient R2

- 0.95

- Explosive coefficient

- 0.3

- Explosive coefficient C1mat4

- 0.036

- Detonation velocity D

- 0.693

- Chapman Jouguet pressure PCJ

- 0.21

- Initial explosive energy per unit initial volume E0mat4

- 0.07

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/MAT/LAW51/2

TNT

# Iform

10

# P_ext NU Nu_Vol

0 0 0

# ALPHA0_mat1 RHO0_mat1 E0_mat1 Pmin_mat1 C0_mat1

0 8.96 0 0 1E-6

# C1_mat1 C2_mat1 C3_mat1 C4_mat1 C5_mat1

1.38 1.372 0 .87 .87

# G1_mat1 a_mat1 b_mat1 n_mat1

.519 9E-4 .00292 .31

# c_mat1 EPSILON_DOT0_mat1

.025 1E-6

# m_mat1 T0_mat1 Tmelt_mat1 Tlim_mat1 Rhocv_mat1

1.09 0 1656 0 3.461E-5

# Epspmax_mat1 sigma_max_mat1 KA_mat1 KB_mat1

0 0 0 0

# ALPHA0_mat2 RHO0_mat2 E0_mat2 Pmin_mat2 C0_mat2

0 .0012 2.5E-6 -1E-20 0

# C1_mat2 C2_mat2 C3_mat2 C4_mat2 C5_mat2

0 0 0 .4 .4

# G1_mat2 a_mat2 b_mat2 n_mat2

0 0 0 0

# c_mat2 EPSILON_DOT0_mat2

0 0

# m_mat2 T0_mat2 Tmelt_mat2 Tlim_mat2 Rhocv_mat2

0 0 0 0 0

# Epspmax_mat2 sigma_max_mat2 KA_mat2 KB_mat2

0 0 0 0

# ALPHA0_mat3 RHO0_mat3 E0_mat3 Pmin_mat3 C0_mat3

0 0 0 0 0

# C1_mat3 C2_mat3 C3_mat3 C4_mat3 C5_mat3

0 0 0 0 0

# G1_mat3 a_mat3 b_mat3 n_mat3

0 0 0 0

# c_mat3 EPSILON_DOT0_mat3

0 0

# m_mat3 T0_mat3 Tmelt_mat3 Tlim_mat3 Rhocv_mat3

0 0 0 0 0

# Epspmax_mat3 sigma_max_mat3 KA_mat3 KB_mat3

0 0 0 0

# ALPHA0_mat4 RHO0_mat4 E0_mat4 Pmin_mat4 C0_mat4

1 1.63 .07 -1E-20 1E-6

# A B R1 R2 W

3.712 .0323 4.15 .95 .3

# D PCJ C1_mat4

.693 .21 .036

/EULER/MAT/2

# Modif. factor.

0

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|- Material Properties

- Initial density

- 0.0012

- Initial energy per unit initial volume E0mat2

- 2.5e-6

- Hydrodynamic cavitation pressure Pminmat2

- -1e-20

- Hydrodynamic coefficient C4mat2

- 0.4

- Hydrodynamic coefficient C5mat2

- 0.4

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/MAT/LAW51/3

Air

# Iform

10

# P_ext NU Nu_Vol

0 0 0

# ALPHA0_mat1 RHO0_mat1 E0_mat1 Pmin_mat1 C0_mat1

0 8.96 0 0 1E-6

# C1_mat1 C2_mat1 C3_mat1 C4_mat1 C5_mat1

1.38 1.372 0 .87 .87

# G1_mat1 a_mat1 b_mat1 n_mat1

.519 9E-4 .00292 .31

# c_mat1 EPSILON_DOT0_mat1

.025 1E-6

# m_mat1 T0_mat1 Tmelt_mat1 Tlim_mat1 Rhocv_mat1

1.09 0 1656 0 3.461E-5

# Epspmax_mat1 sigma_max_mat1 KA_mat1 KB_mat1

0 0 0 0

# ALPHA0_mat2 RHO0_mat2 E0_mat2 Pmin_mat2 C0_mat2

1 .0012 2.5E-6 -1E-20 0

# C1_mat2 C2_mat2 C3_mat2 C4_mat2 C5_mat2

0 0 0 .4 .4

# G1_mat2 a_mat2 b_mat2 n_mat2

0 0 0 0

# c_mat2 EPSILON_DOT0_mat2

0 0

# m_mat2 T0_mat2 Tmelt_mat2 Tlim_mat2 Rhocv_mat2

0 0 0 0 0

# Epspmax_mat2 sigma_max_mat2 KA_mat2 KB_mat2

0 0 0 0

# ALPHA0_mat3 RHO0_mat3 E0_mat3 Pmin_mat3 C0_mat3

0 0 0 0 0

# C1_mat3 C2_mat3 C3_mat3 C4_mat3 C5_mat3

0 0 0 0 0

# G1_mat3 a_mat3 b_mat3 n_mat3

0 0 0 0

# c_mat3 EPSILON_DOT0_mat3

0 0

# m_mat3 T0_mat3 Tmelt_mat3 Tlim_mat3 Rhocv_mat3

0 0 0 0 0

# Epspmax_mat3 sigma_max_mat3 KA_mat3 KB_mat3

0 0 0 0

# ALPHA0_mat4 RHO0_mat4 E0_mat4 Pmin_mat4 C0_mat4

0 1.63 .07 -1E-20 1E-6

# A B R1 R2 W

3.712 .0323 4.15 .95 .3

# D PCJ C1_mat4

.693 .21 .036

/EULER/MAT/3

# Modif. factor.

0

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|Using the Multi-Material Solid, Liquid, and Gas material law (/MAT/LAW51), the Boundary material has the following characteristics.

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/MAT/LAW51/4

Boundary

# Iform

3

# ALPHA_1 RHO_01 E_01 P_min1 C_01

0 8.96 0 0 1E-6

# ALPHA_2 RHO_02 E_02 P_min2 C_02

1 .0012 2.5E-6 -1E-20 1E-6

# ALPHA_3 RHO_03 E_03 P_min3 C_03

0 0 0 0 0

/EULER/MAT/4

# Modif. factor.

0

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|Model Method

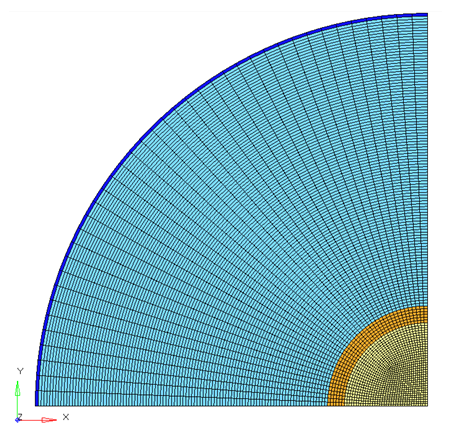

A 3D mesh is made of brick elements. The element size for the copper cylinder is approximately of 0.035 cm x 0.035 cm x 0.035 cm.

The mesh is dragged along the z direction (z = 30.5 cm). It is important to have no discontinuity in element volume in order to ensure a good propagation of detonation wave and shock wave.

Figure 2. Model Mesh

Results

Curves and Animations

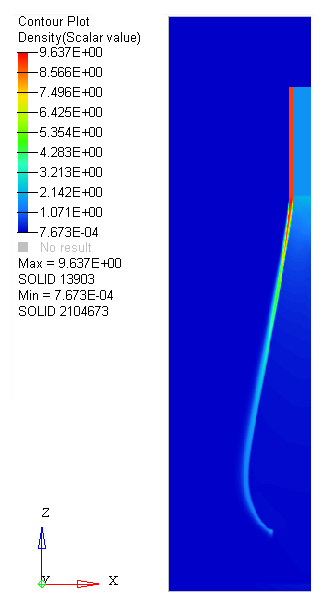

Figure 3. Density Distributed in Copper and TNT at time = 33s

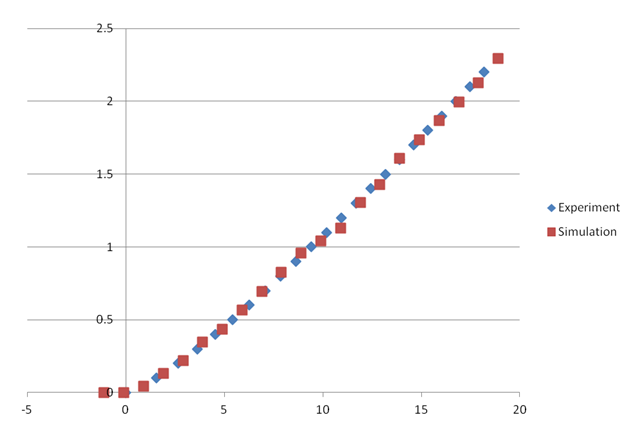

Figure 4. Comparison Between Experimental Results and Simulation Results

Conclusion

Good correlation between experimental and simulation results. A thinner meshing could improve the correlation between simulation and experimental curves.