Example: High Velocity Impacts

A typical application of the ALE method is using high velocity impacts.

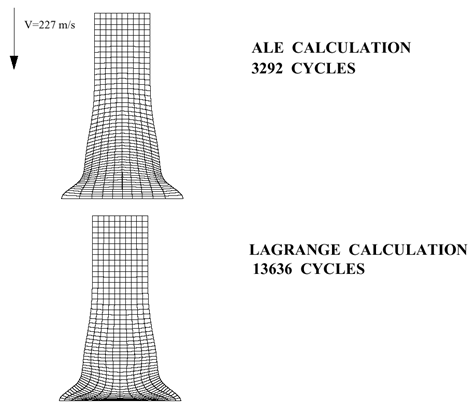

Figure 1. Cylinder Impact Deformation

It can be seen that the cylinder mesh using ALE remains regular, unlike the Lagrange method, where large element deformation creates very small and skewed elements. This reduces the time step, leading to more time step cycles. However, each ALE cycle takes longer than a Lagrangian.