Fast Cool Analysis |

|

|

|

|

|

Fast Cool Analysis |

|

|

|

|

Moldex3D solver supports fast cool analysis and standard cool analysis for a solid mesh model. In standard cool analysis, all the meshes are solid meshes. In fast cool analysis, meshes for moldbase and mold insert are surface meshes instead of the solid meshes. Meshes for coolant channel and heating rod are 1D beam meshes instead of the regular solid meshes. Under this category, you can assign properties to surface meshes of moldbase and mold insert, and also to beam meshes of coolant channel and heating rod.

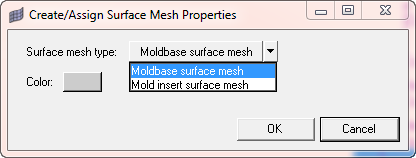

Moldbase and mold insert surface mesh properties can be assigned. Click Surface Mesh to display a selector for selecting surface elements. After surface selection, the following dialog appears.

Neither of the surface mesh types have any attributes to be specified. The Color button can be used to assign color to the component where the selected elements will be moved to. Moldbase surface mesh elements are moved to a component collector named MoldBase and are assigned a property named MoldBase. Mold insert surface mesh elements are moved to component collector named MoldInsert and are assigned a property named MoldInsert.

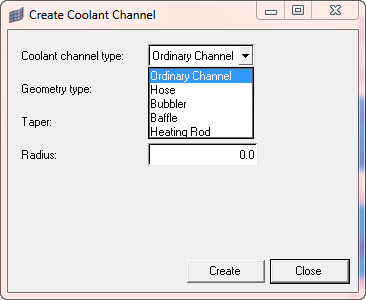

Using this macro button, you can assign/edit properties to coolant channel and heating rod. In the current Moldex3D solver, only circular cross-section for coolant channel and heating rod is supported. The same is supported in this interface as well. After clicking this button, a selector for selecting the elements will appear. Beam elements with the tag of coolant channel are the valid elements.

As shown in the figure above, only these 5 types of coolant channels are supported.

| • | For Ordinary Channel, Hose and Heating Rod the geometry types supported are Circular and Friction. |

| • | For circular cross-section, radius needs to be specified. |

| • | For Friction, friction factor and heat transfer coefficient needs to be specified. Taper is allowed only for Heating Rod type of coolant channel with circular cross-section. |

| • | For Bubbler and Baffle, drawing of surfaces for visualization is not supported. Elements selected are moved to a component collector named CoolantChannel. Properties assigned to coolant channel and heating rod will have names such as CoolantChannel.1, CoolantChannel.2 and so on. |