Example: DOE Using OptiStruct

In this example, you will learn how to perform a design of experiments (DOE) using the Design Explorer workflow.

Before you begin, copy the model used in this example from <HyperWorks

Installation Directory>/tutorials/hwdesktop/hwx/ to your working directory.

- bikeFrame.hm

Open the Model

- Start HyperWorks.

- From the menu bar, click File > Open > HyperMesh Model.

-

Browse to your working directory, select bikeFrame.hm, and

click Open.

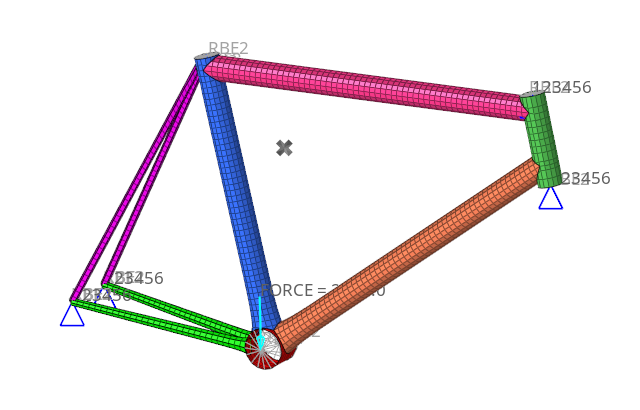

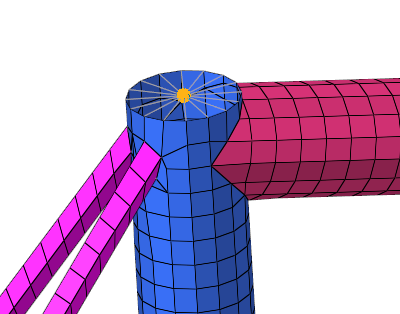

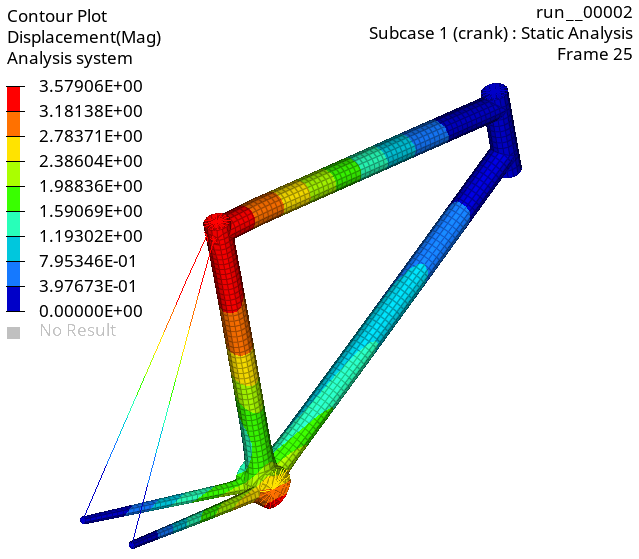

If prompted, click Change to change the solver interface to OptiStruct while opening the model.A finite element model appears in the modeling window.

Figure 1.

Create an Exploration

-

From the Design Explorer ribbon, Exploration tool group, click the

Create Explorations tool.

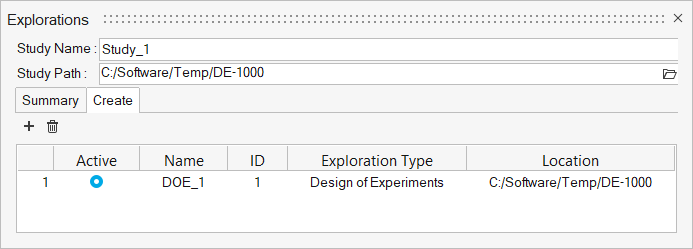

Figure 2.The Explorations dialog opens. -

Click

then select DOE.

then select DOE.

-

In the Study Path field, browse to and select the folder to store your

DOE.

Figure 3. -

From the Exploration tool group, click the Design

Explorer tool.

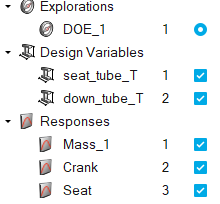

Figure 4.The Design Explorer browser opens. You can see the newly created optimization exploration. Additional exploration entities will appear here as well.

Create the Exploration Inputs

-

From the Design Explorer ribbon, click the Gauge

tool.

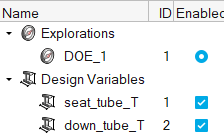

Figure 5. - In the modeling window, select the blue seat_tube property and the orange down_tube property.

-

In the microdialog, click

Create.

Two gauge design variables are created.

Figure 6.

Create the Exploration Responses

-

From the Design Explorer ribbon, click the Mass/Volume

tool.

Figure 7. -

On the guide bar, click

.

A mass response is created.

.

A mass response is created. -

Click the Disps. tool.

Figure 8. -

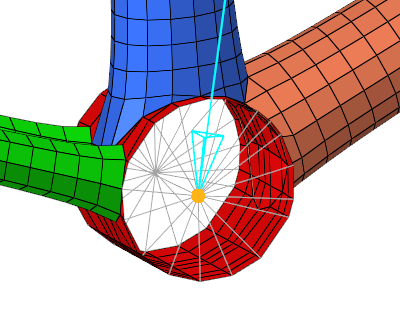

In the modeling window, select the node where the crank

load is applied.

Figure 9. -

In the microdialog, click

.

An Entity Editor window appears.

.

An Entity Editor window appears.- Change the response name to Crank.

- From the Response Component drop-down menu, select Z.

- Click Close.

The displacement response is updated. -

On the guide bar, click

.

.

-

Select the node where the seat sits.

Figure 10.A second displacement response is created. -

In the microdialog, click

.

An Entity Editor window appears.

.

An Entity Editor window appears.- Change the response name to Seat.

- From the drop-down menu, select MAG.

- Click Close.

The displacement response is updated. -

On the guide bar, click

.

.

Figure 11.

Evaluate the Exploration

-

From the Design Exploration ribbon, Evaluate tool group, click the

Evaluate tool.

Figure 12.The Evaluate dialog opens. -

Click Export then click

Run.

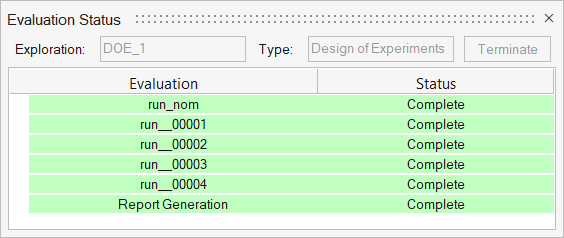

The DOE is evaluated. In this case, there will be a nominal run plus four DOE runs.

This may take a few minutes depending on your computer.

When the evaluation is complete, the Evaluation Status dialog should look like Figure 13.

Figure 13.

Review the Evaluation

-

From the Design Explorer ribbon, Evaluate tool group, click the

Results Explorer tool.

Figure 14.The Results Explorer browser opens. -

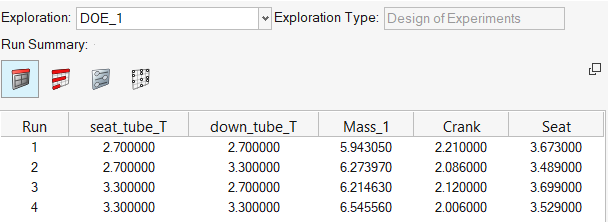

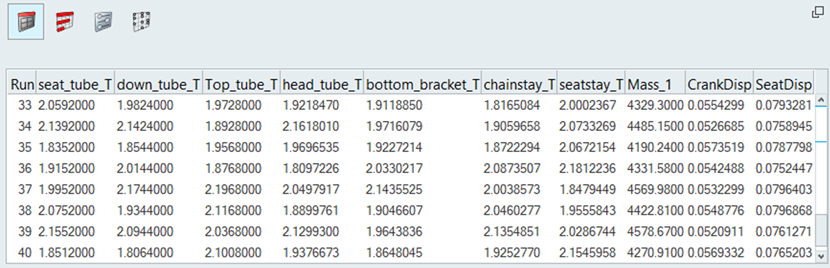

Review the Summary table, which shows the input and response values for each

run of the DOE.

Figure 15. -

Right-click on any row in the Summary table and select Load

Results.

A HyperView window opens, and the results contour from the selected run is displayed.

Figure 16. -

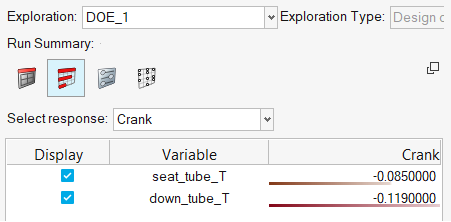

In the Results Explorer, click the Linear Effects button

(

).

).

-

From the Select response drop-down menu, select

Crank.

The Linear Effects plot shows the relative contribution of each design variable on the crank displacement response.

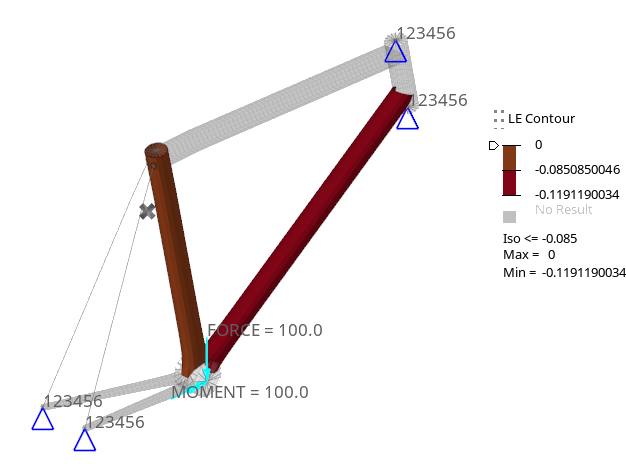

Figure 17.Note: Notice the negative correlation between the gauge design variables and the displacement response. This indicates that an increase in the gauge of the component will result in a corresponding decrease to the displacement response. In addition, the relative effect of a change to the down tube thickness will be greater than a similar change to the seat tube thickness.In addition, the effects contour is mapped onto the model itself in the graphics area for visualization.

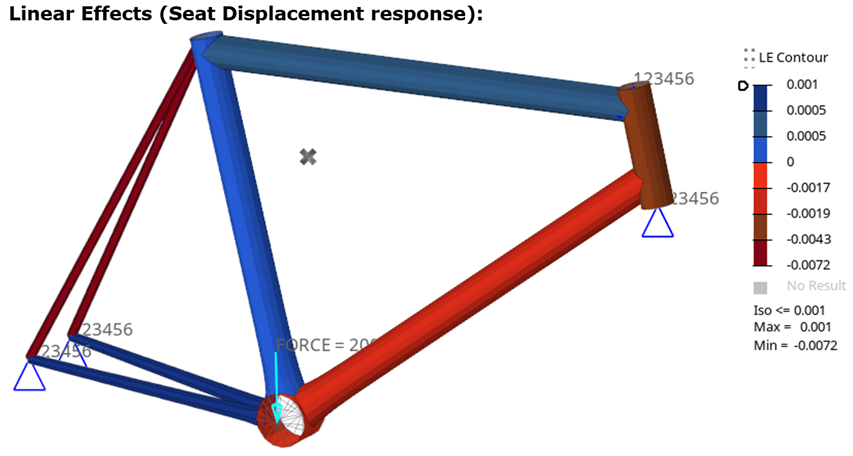

Figure 18.Note: This can be quite useful when dealing with a larger number of design variables.In the table as well as on the model, positive effects – indicating a positive relationship between the design variable and response – are shown in shades of blue, whereas negative effects – indicating an inverse relationship between the design variable and response – are shown in shades of brown.

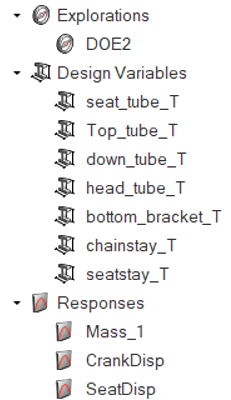

-

As an exercise, try creating a similar DOE where the gauge of every component

is a design variable. Your DOE and reports should look something like the

following (your actual values will vary, based on your specific design variable

bounds choices).

Figure 19.

Figure 20.

Figure 21.