Pre-Simulation (Seat Deformer) Setup

Export an input deck, for the appropriate solver, in order to simulate the deformation of the seat under the dummy. The simulation result files can be imported to update the initial FE model and remove the intersections and penetrations between the dummy and the seat.

When a dummy is positioned to its H-Point location on a seat, intersections between the dummy and seat foam parts generally occurs.

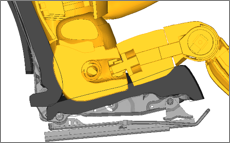

Figure 2. . Shows the initial model with the dummy positioned at its correct H-Point location, and shows intersections with the seat.

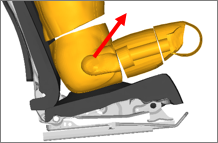

Figure 3.

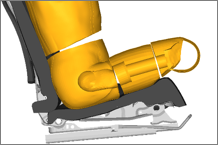

Figure 4.

PreSimulation Tool

Overview of the PreSimulation Tool user interface.

LS-DYNA

| Option | Description |

|---|---|

| Unit System | Selecting a unit system will automatically set up the default simulation parameters to the correct unit. In any case, you can still modify these values manually. |

| Dummy | Dummy components that are selected in contact with the seat will be exported

for the pre-simulation. The selection can be done via:

|

| Seat | Select the seat components that will be exported for the pre-simulation. The

selection can be done via:

|

| Fixed Nodes of Seat | Select the nodes that will be fixed during the simulation. The selection can

be done via:

|

| Dummy Displacement Direction | Defines the vector in which the dummy components will be moved to the starting simulation position when penetrations with the seat are no longer detected. |

| Export Files | Defines the pre-simulation deck name and location. |

| Dummy Velocity | Defines the imposed velocity value applied on the dummy parts during the simulation. Default value = 0.1mm/ms. |

| Time Step | Defines the control time step value. Default value = 0.001ms. |

| Scale Materials Density | Scale factor to scale the material density values in order to increase the critical time step of the model. Default value = 10. |

| Dummy Displacement Step | Displacement increment used to move the selected dummy components along the prescribed vector. After each increment, the penetration check between the dummy and seat will be performed and the dummy motion will be stopped when penetrations are no longer detected. Default value = 10. |

| Soft | Defines the Soft parameter value in the generated contact between the dummy and seat. Default value = 2. |

| Friction | Defines the FS parameter value in the generated contact between the dummy and seat. Default value = 0.0. |

| Imposed Contact Thickness | Defines the value of parameters SST, MST and SLDTHK in the generated contact between the dummy and seat. Default value = 0.0. |

| Contact Stiffness Scale Factor | Defines the value of parameter SFS in the generated contact between the dummy and seat. Default value = 0.0. |

| Import *INITIAL_STRESS_SOLID | If this checkbox is activated, initial stresses for solid elements will be imported from the dynain file. This option is activated by default. |

| Import *INITIAL_STRESS_SHELL | If this checkbox is activated, initial stresses for shell elements will be imported from the dynain file. This option is deactivated by default. |

| Import *INITIAL_STRESS_BEAM | If this checkbox is activated, initial stresses for beam elements will be imported from the dynain file. This option is deactivated by default. |

| Export | Starts the export process of the pre-simulation deck at the specified location. |

| Import dynain File | Allows the LS-DYNA simulation to update the initial model. |

| Close | Closes the dialog. |

Radioss

| Option | Description |

|---|---|

| Unit System | Selecting a unit system will automatically set up the default simulation parameters to the correct unit. In any case, you can still modify these values manually. |

| Dummy | Dummy components that are selected in contact with the seat will be exported

for the pre-simulation. The selection can be done via:

|

| Seat | Select the seat components that will be exported for the pre-simulation. The

selection can be done via:

|

| Fixed Nodes of Seat | Select the nodes that will be fixed during the simulation. The selection can

be done via:

|

| Dummy Displacement Direction | Defines the vector in which the dummy components will be moved to the starting simulation position when penetrations with the seat are no longer detected. |

| Export File | Defines the pre-simulation deck name and location. |

| Generate XREF for initial stresses | Enables the creation of /XREF cards for the seat components that are compatible with this Radioss feature in terms of material type and element formulation. This checkbox is activated by default. |

| Dummy Velocity | Defines the imposed velocity value applied on the dummy parts during the simulation. Default value = 0.1mm/ms. |

| Time Step | Defines the control time step value. Default value = 0.001ms. |

| Scale Materials Density | Scale factor to scale the material density values in order to increase the critical time step of the model. Default value = 10. |

| Dummy Displacement Step | Displacement increment used to move the selected dummy components along the prescribed vector. After each increment, the penetration check between the dummy and seat will be performed and the dummy motion will be stopped when penetrations are no longer detected. Default value = 10. |

| Friction | Defines the friction value in the generated contact between dummy and seat. Default value = 0.0. |

| Stmin | Defines the minimum contact stiffness in the generated contact between dummy and seat. Default value = 1.0kN/mm. |

| Gap_Min | Defines the minimum gap in the generated contact between dummy and seat. Default value = 0.5. |

| IGAP | Defines the IGAP value for the generated contact between dummy and seat. Default value = 2. |

| Export | Starts the export process of the pre-simulation deck at the specified location. |

| Import h3d File | Allows the Radioss simulation to update the initial model. |

| Close | Closes the dialog. |