ACU-T: 3201 Solar Radiation and Thermal Shell Tutorial

This tutorial introduces you to setting up a CFD simulation involving solar radiation and thermal shells using AcuSolve and HyperWorks CFD. Prior to starting this tutorial, you should have already run through the introductory tutorial, ACU-T: 1000 Basic Flow Set Up, and have a basic understanding of HyperWorks CFD, AcuSolve, and HyperView. To run this simulation, you will need access to a licensed version of HyperWorks CFD and AcuSolve.

Prior to running through this tutorial, copy HyperWorksCFD_tutorial_inputs.zip from <Altair_installation_directory>\hwcfdsolvers\acusolve\win64\model_files\tutorials\AcuSolve to a local directory. Extract ACU-T3201_Atrium.x_t and SolarLoad.dat from HyperWorksCFD_tutorial_inputs.zip.

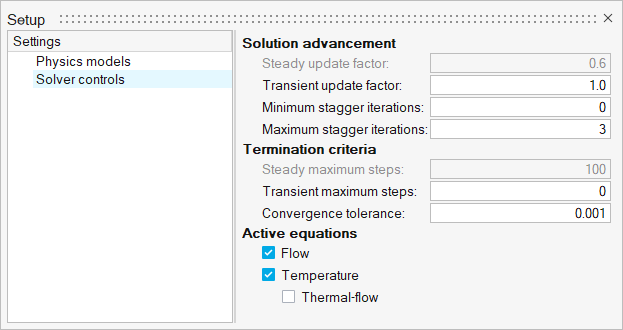

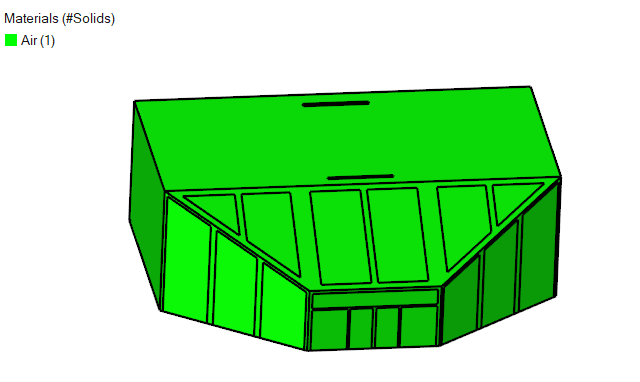

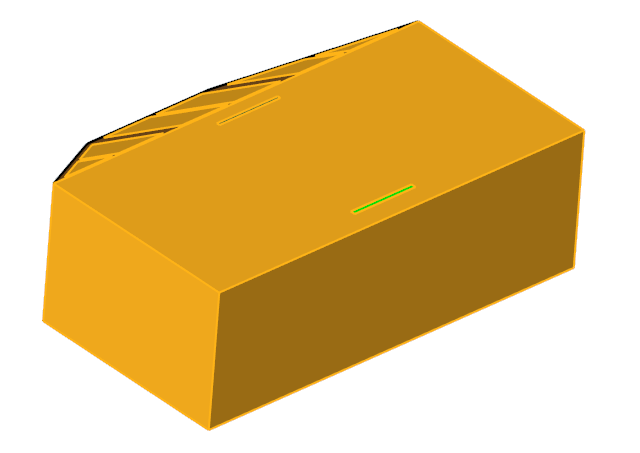

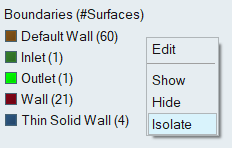

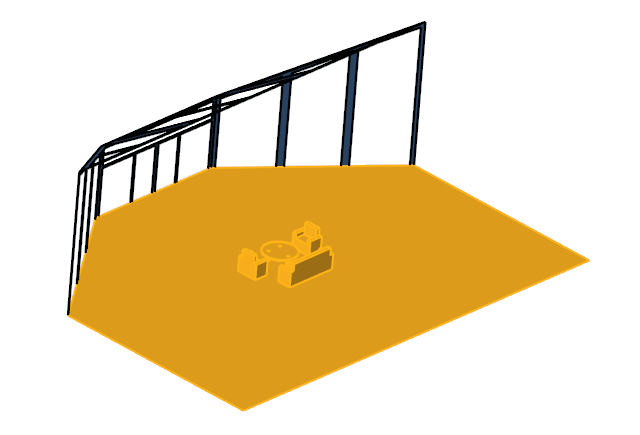

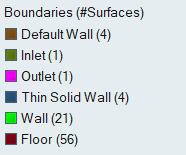

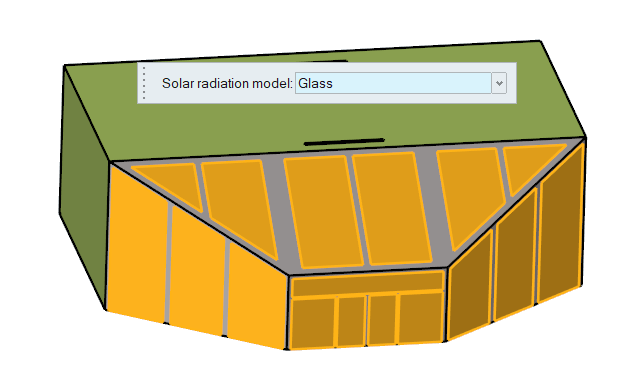

Problem Description

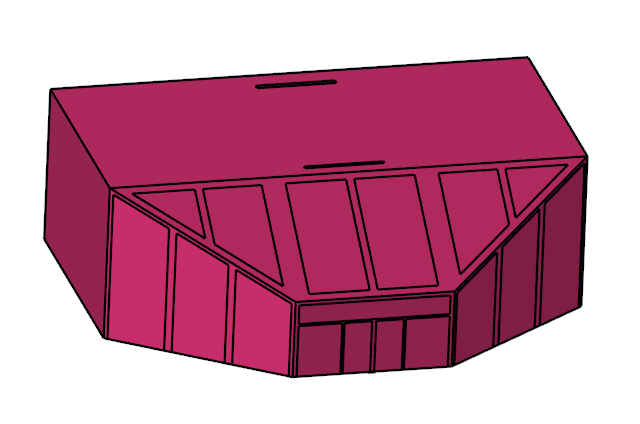

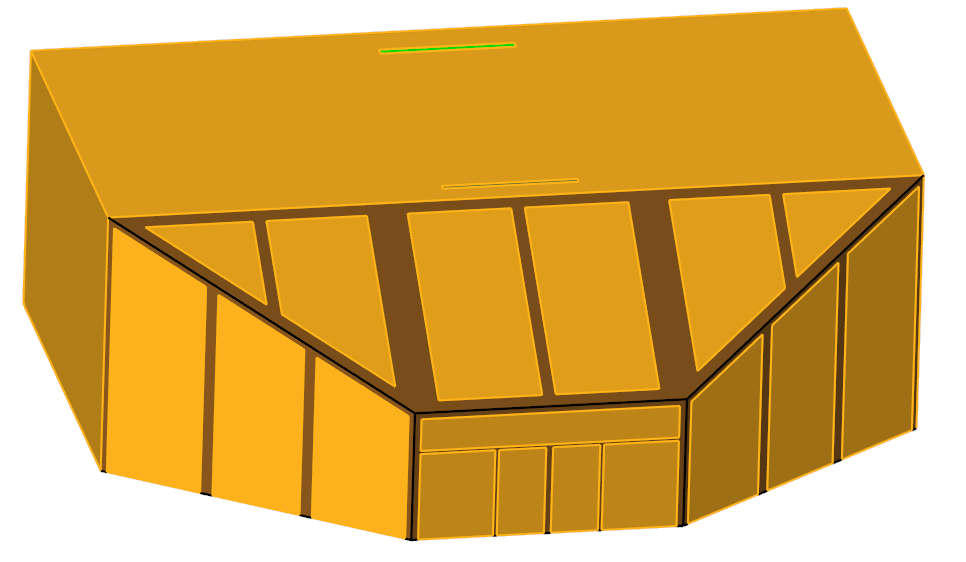

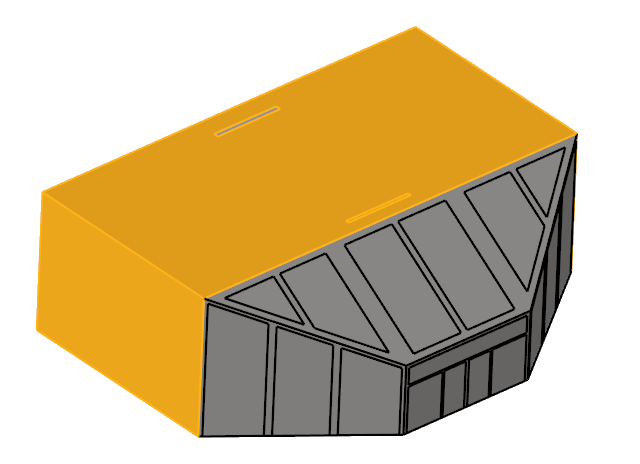

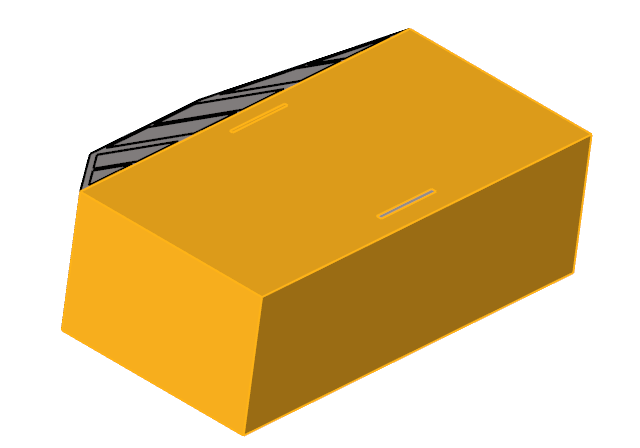

Figure 1.

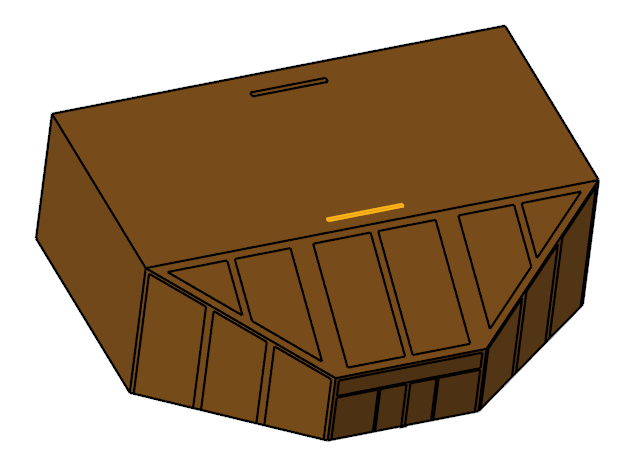

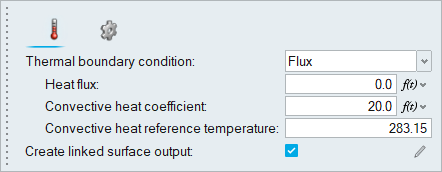

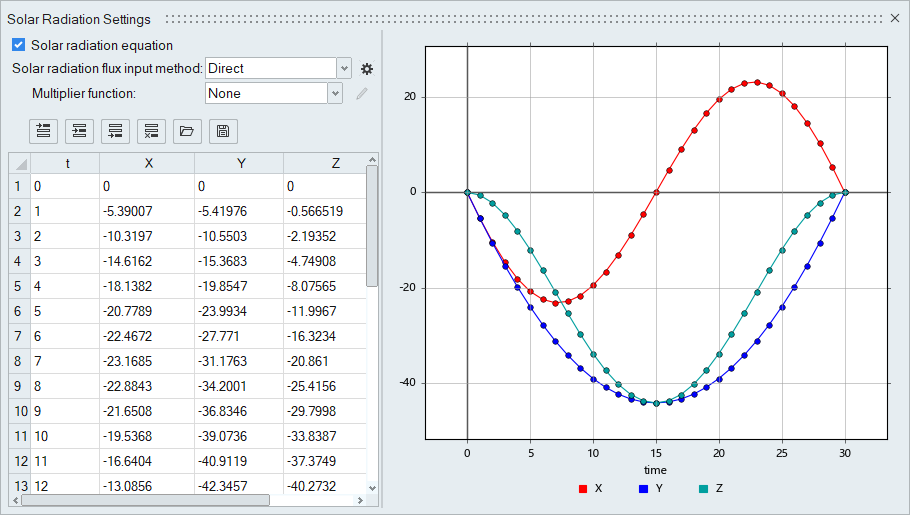

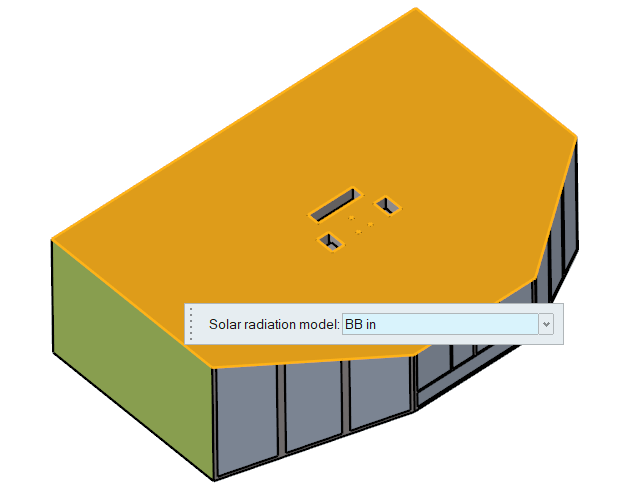

Solar Radiation Parameters

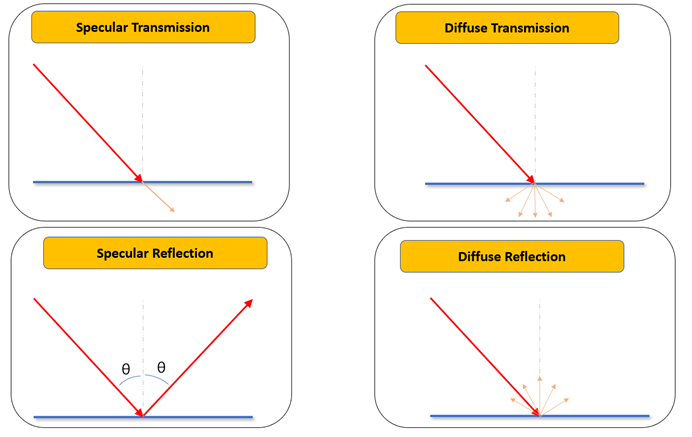

Figure 2.

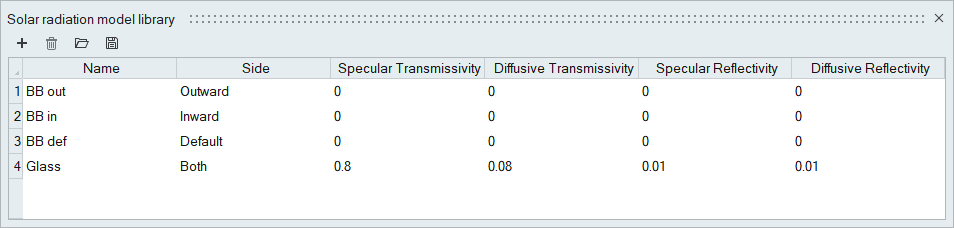

- Specular transmissivity

- Diffuse transmissivity

- Specular reflectivity

- Diffuse reflectivity

- Absorptivity

- Angle of incidence

For the solar radiative heat fluxes to be computed, a solar radiation surface needs to be defined on that given surface.

In this tutorial, the solar flux loading is given in the form of a data file which was generated using the acuSflux script available in AcuSolve. The script can be used to generate a data file with a four-column array of solar flux vector data values. The piecewise linear type is used in this tutorial to emulate the pattern of sunrise to sunset over the atrium.

For example, to generate the solar load data file for a location with known geological coordinates, enter the following command in the AcuSolve Command Prompt: acuSflux -time "dec-3-2019 11:00:00" -tinc 1800 -nts 25 -lat 42.6064 -lon -83.1498 -ndir "1,0,0" -udir "0,0,1"

- time

- The start time in GMT (ex: “dec-3-2019 21:00:00”)

- tinc

- The time increment in seconds

- nts

- Number of discrete time steps

- lat

- Latitude coordinates of the location in degrees North (ex: 45.112 or -37.56 (equal to 37.56 S))

- lon

- Longitude coordinates of the location in degrees East (ex: 86.26 or -54.84 (equal to 54.84 W))

- ndir

- The north direction unit vector in model coordinates (should be enclosed in double quotes) (ex: “0,1,0”)

- udir

- The upward direction unit vector in model coordinates (should be enclosed in double quotes) (ex: “0,1,0”)

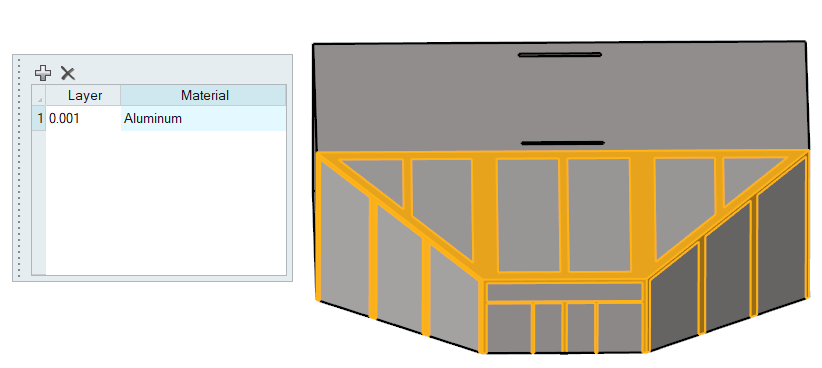

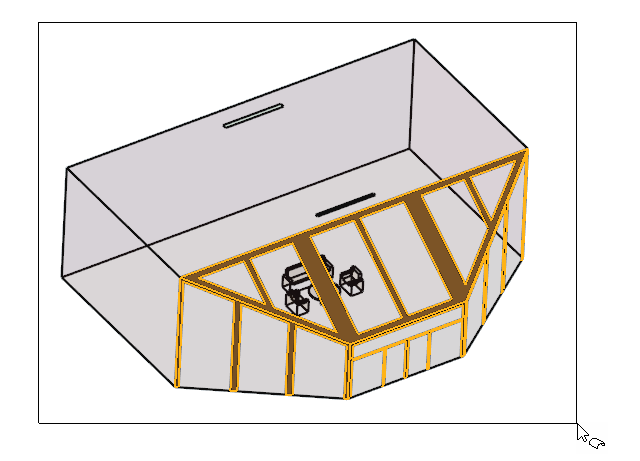

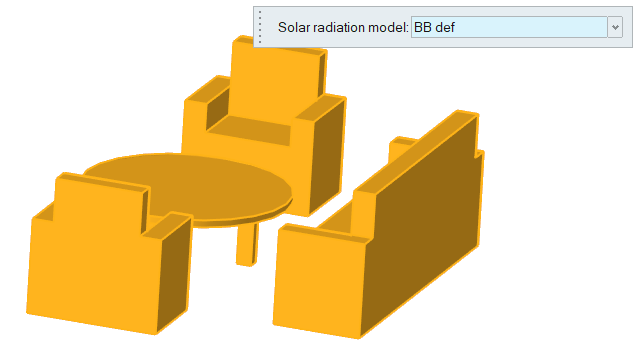

Thermal Shell Modeling

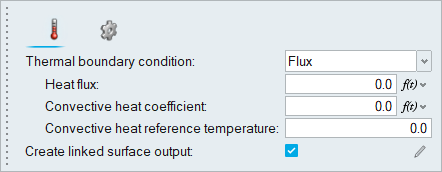

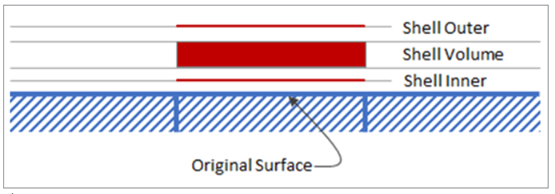

Figure 3.

When defining a thermal shell on a surface, two sets of boundary conditions are needed. One for the Primary Wall surface i.e. Shell Inner and one for the Shell Outer Wall surface. In this tutorial, a solar radiation surface will be defined on the outer shell surface so that it receives solar heat flux, whereas the inner shell surface will be modeled as a default wall.

Start HyperWorks CFD and Create the HyperMesh Model Database

Import and Validate the Geometry

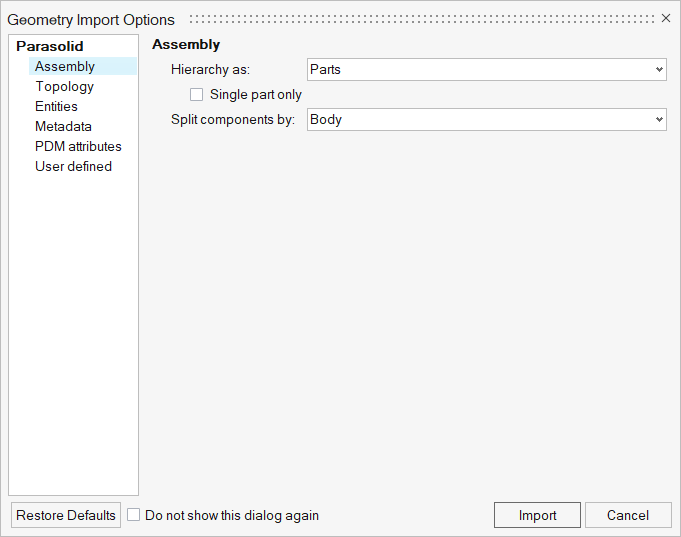

Import the Geometry

Validate the Geometry

Set Up Flow

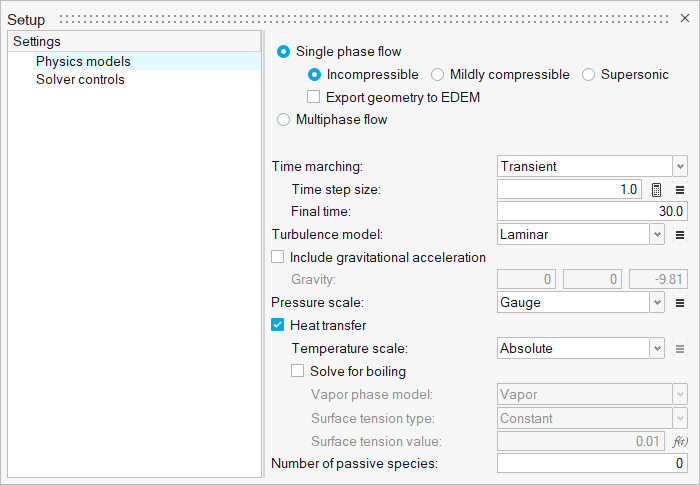

Set Up the Simulation Parameters and Solver Settings

Assign Material Properties

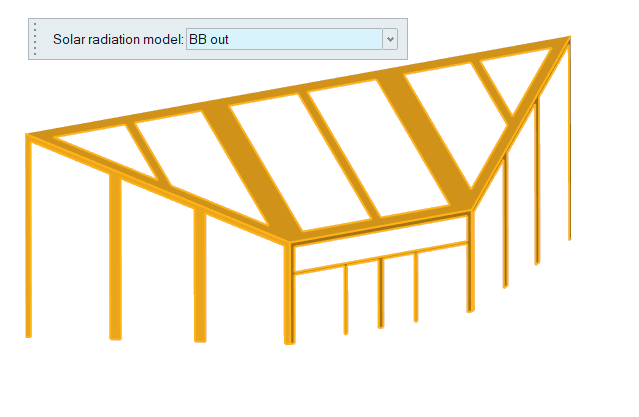

Define Thin Solids

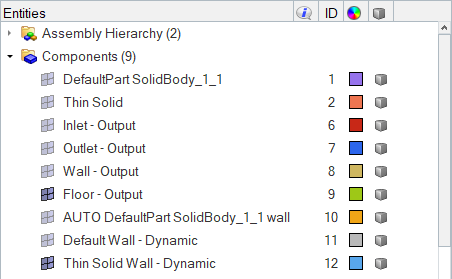

In this simulation, you will model the aluminum frames as a thin solid.

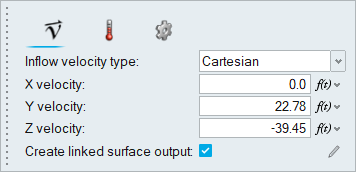

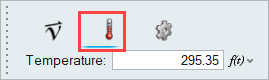

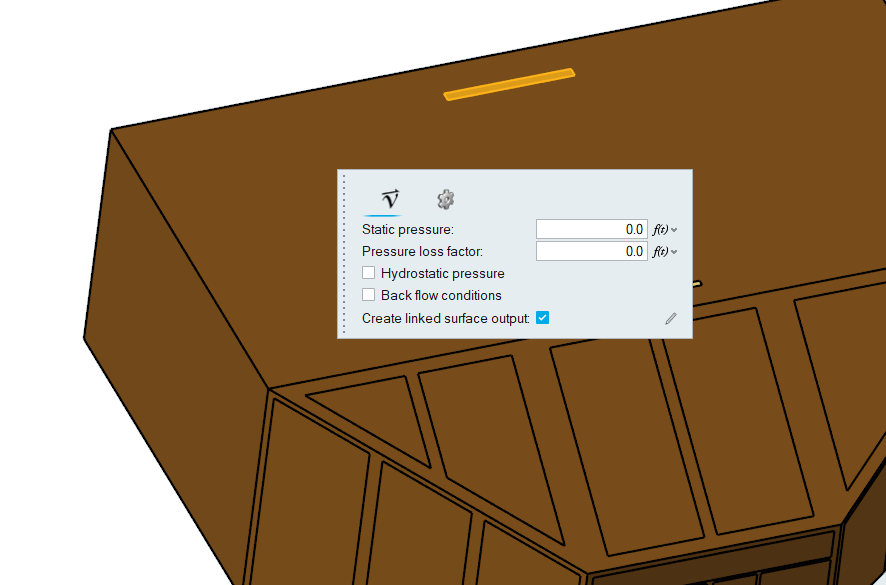

Define Flow Boundary Conditions

Set Up Solar Radiation

Set Up the Solar Radiation Parameters

Define the Solar Radiation Models

Assign the Solar Radiation Models

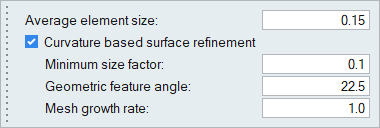

Generate the Mesh

In this step, you will define the mesh controls and then generate the mesh.

Define the Surface Mesh Controls

Generate the Mesh

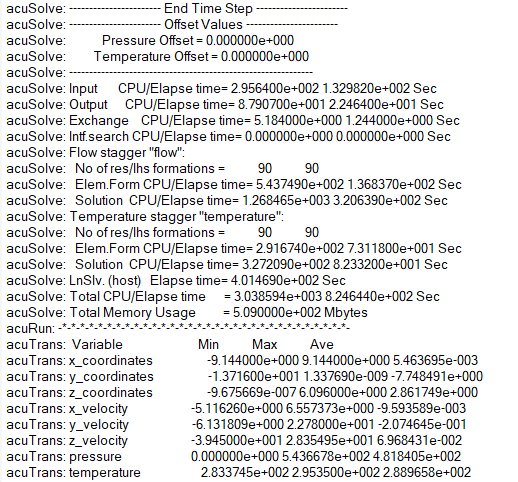

Compute the Solution

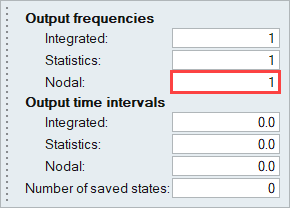

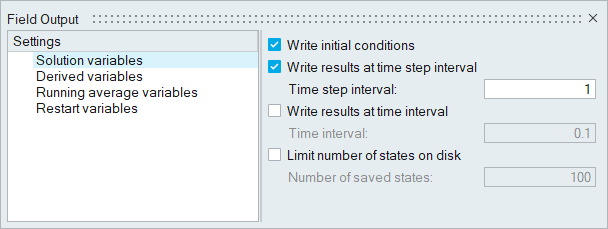

Define the Nodal Output Frequency

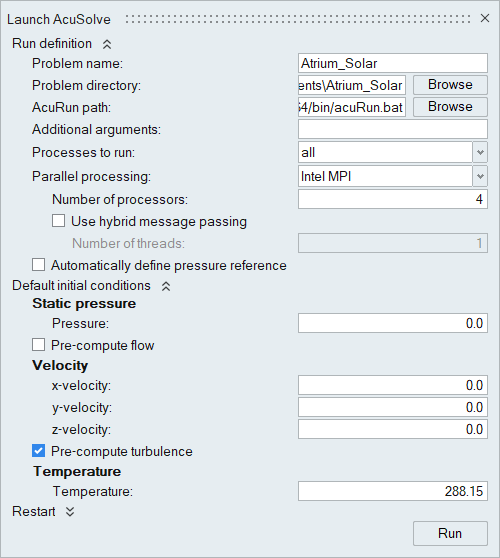

Define the Nodal Initial Conditions and Compute the Solution

Post-Process the Results with HyperView

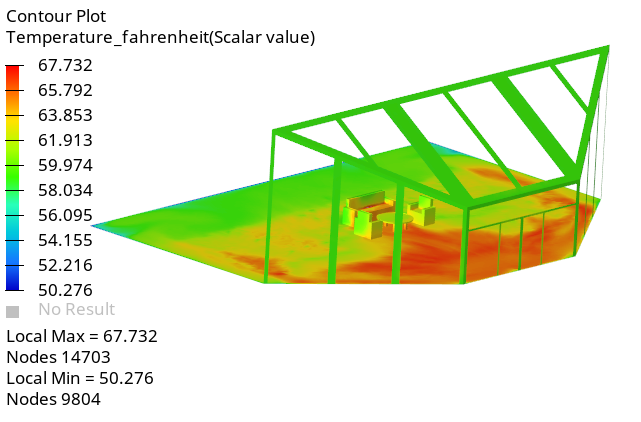

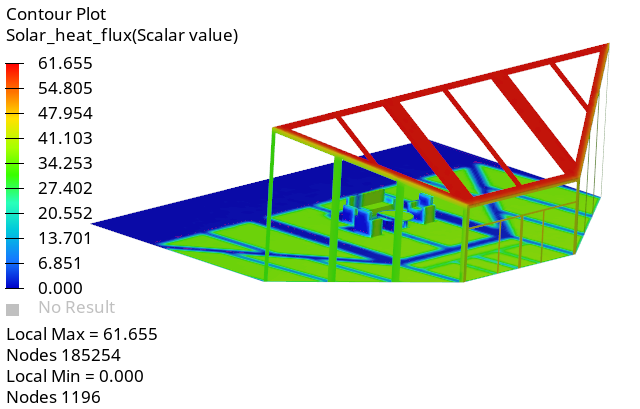

In this step, you will create an animation of solar heat flux and temperature over run time.

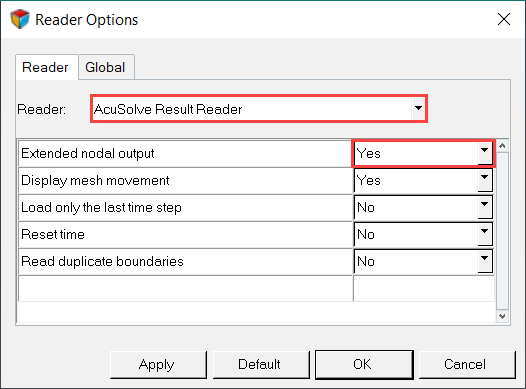

Open HyperView and Load the Model and Results

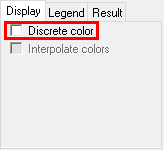

Create an Animation of Temperature Contour

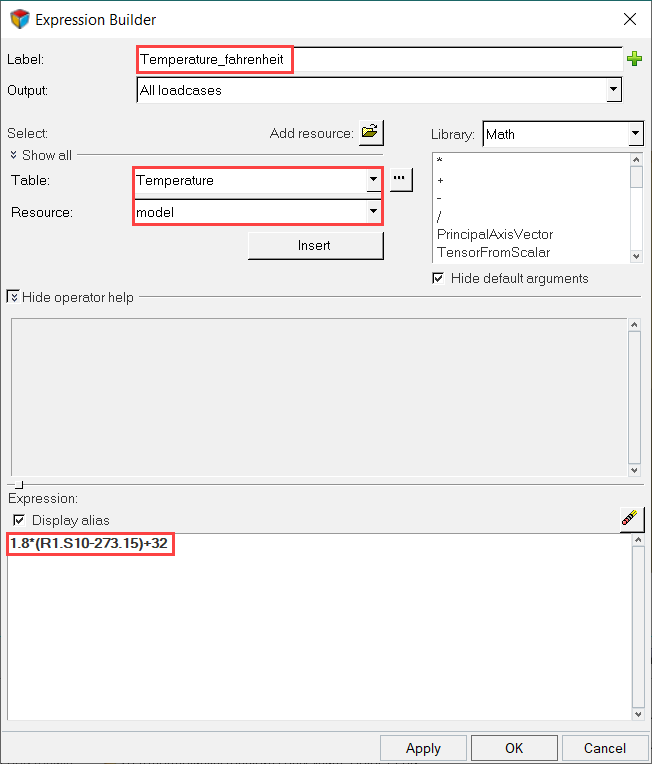

In this step, you will start by creating an expression for plotting the temperature values in Fahrenheit units. Then, you will create an animation of the magnitude of temperature on the floor and the thin solid wall surfaces.

Create an Animation of Solar Heat Flux

Summary

In this tutorial, you learned how to set up and solve a CFD analysis involving solar radiation. You started by importing a geometry model into HyperWorks CFD and setting up the simulation parameters and boundary conditions. Once you computed the solution, you post-processed the results using HyperView. Also, you learned how to create expressions in HyperView so that you can build plots of derived results.