Add/Edit Nozzles

Add or edit a nozzle system that includes travel paths or stationary points for releasing the foaming chemicals into the mold, nozzle size, foam injection direction, mass flow rate, and material-flow start and end times.

-

Click the Nozzle icon.

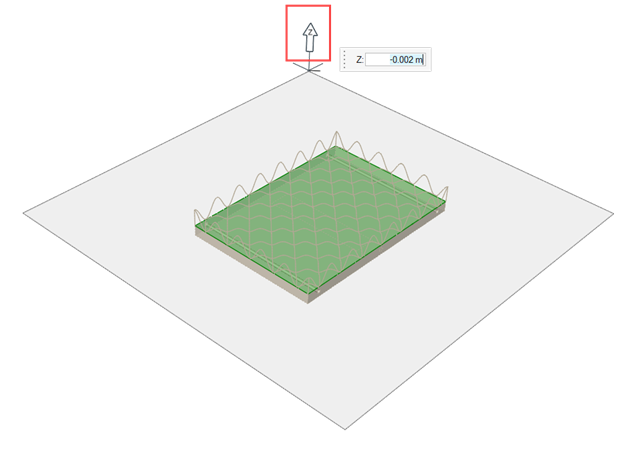

A plane appears for you to define the location of the nozzle relative to the part. -

Adjust the plane with the Move tool or enter the value in the

microdialog.

Tip: Zoom out on your model if the Move tool is hidden from view. Alternatively, click once outside of the part on the plane.

-

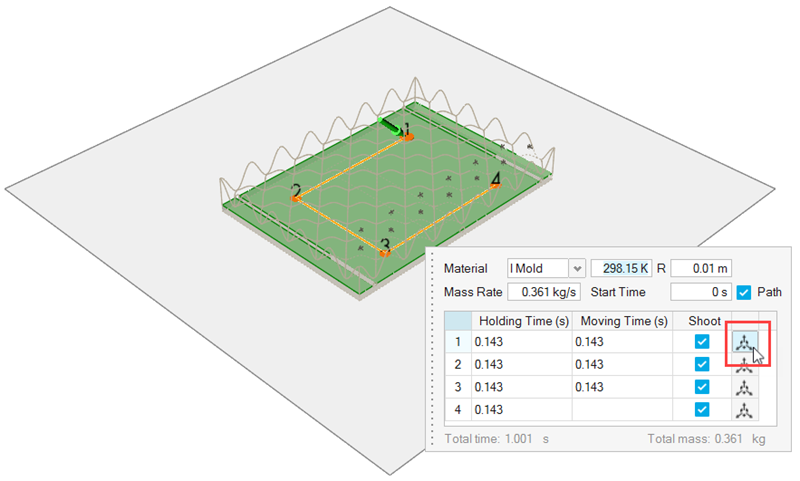

Click on the plane to place the first injection point for the nozzle.

Tip: Place the points within the width and length of the part cavity.

-

Create a path or a stationary entry point for the nozzle.

- To create a path, select the Path check box in the dialog. On the plane, move your mouse to sketch, then click to place the points of the path.

- To create fixed injection points, click on the plane at the desired locations just as you placed the first point.

-

After placing your last point, right-click.

The points are listed on the table in the dialog in the order that you placed them.

-

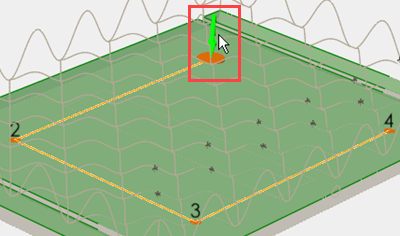

To modify the location of a point, click the Move button

for the point in the table.

for the point in the table.

-

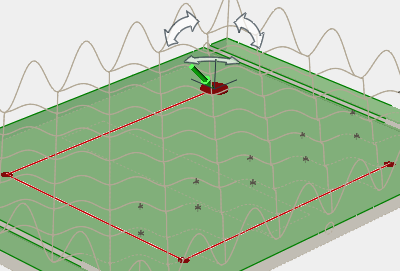

To modify the foam injection direction for a path or point, double-click the

green arrow.

-

Click and drag the arrows of the Move tool to change the injection direction or

enter new coordinates for the X, Y and Z directions in the microdialog.

-

After defining the nozzle path, points, and injection direction, define the

remaining parameters in the dialog for the foaming material and injection

process.

Parameter Description Material Select a foaming material from the menu. Temperature Enter the temperature of the selected foaming material. R Enter the radius of the nozzle. Mass Rate Enter the mass rate (Flow rate * density) for the material. Start Time Enter the start time for the material to flow. Path Select the check box to create a nozzle path, rather than a stationary point. Shoot Select to open the shoot and enable material to flow from the nozzle into the mold. Clear to close the shoot and stop the flow. Holding Time Enter the time that the nozzle should remain on the path point. Moving Time Enter the time for the nozzle to move from one point to the next on the path. Do this for each point in the table. Move Point

Use the Move tool to change the location of a point. - Double right-click to confirm your nozzle system.