Application Area 7: Minimize Energy Consumption

Often, machines are required to perform repetitive tasks. An example is a robot in a manufacturing line. It is required to pick up a component at one location and deposit it at another location. The delta robot shown below is one such robot.

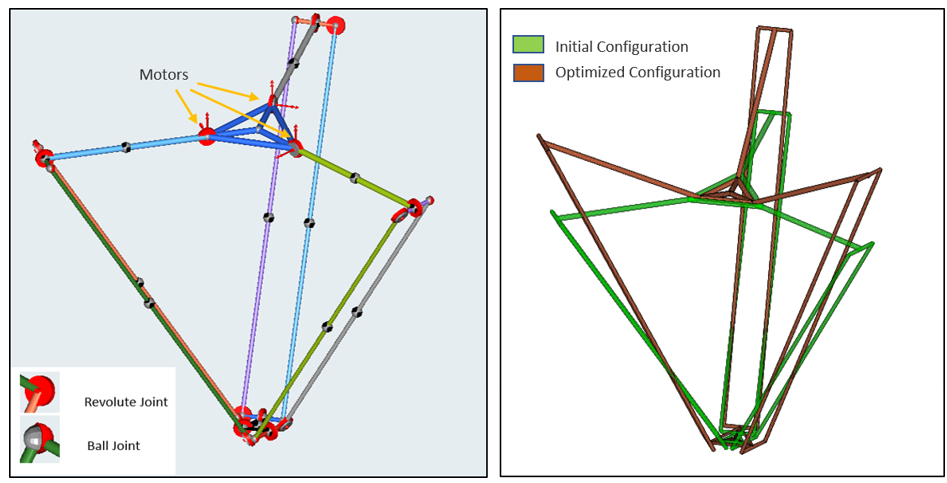

Delta robots are parallel robots that allow motion of an end-effector platform parallel to a base. They are extensively used for pick-and-place applications in packaging industry, high precision assembly operations in electronics and in 3D printers as they are capable of high speed operations. The model shown below has 3 degrees of freedom – three translations of the end-effector.

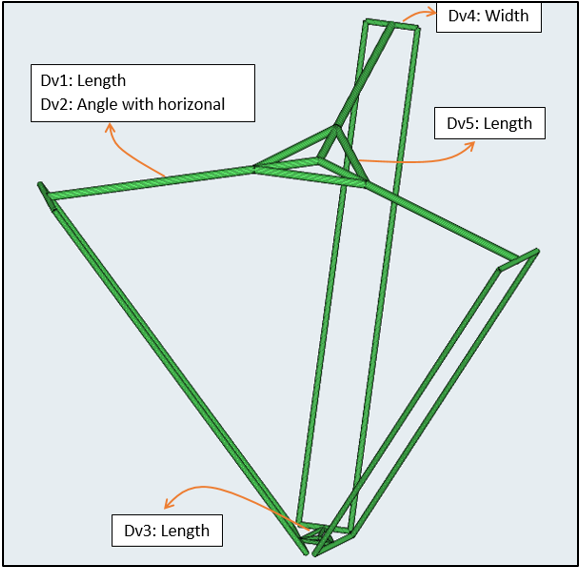

Figure 1.

- Objective

- Synthesize a robot configuration that consumes the least energy while the end effector traverses a given path

- Design Variables

- This delta robot has five design variables. These are shown in the image below.

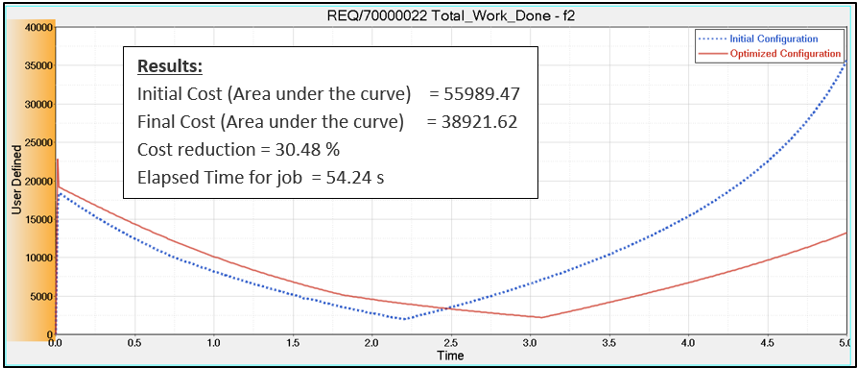

- Results

- The total energy consumed by the three motors was reduced by 30%; the peak torque for one of the motor also reduced by more than 57% in the optimal design configuration.