What's New

View new features for MotionSolve 2021.2.

Altair MotionSolve 2021.2 Release Notes

General

New Features

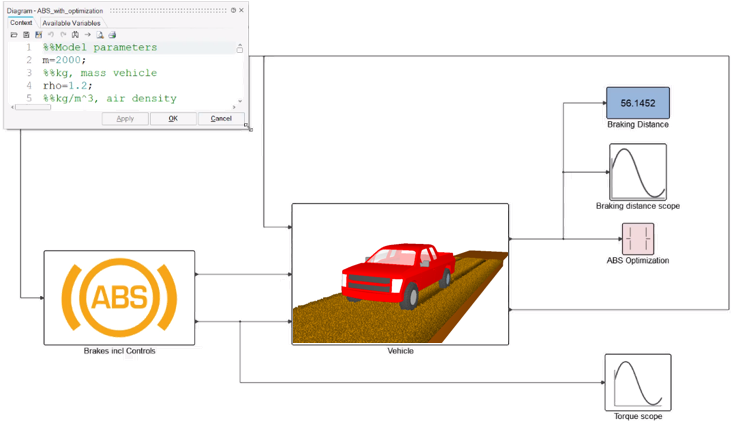

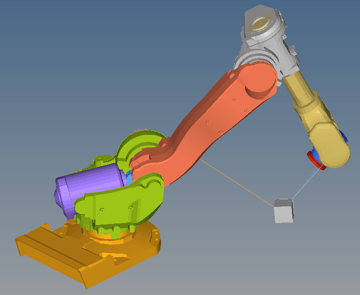

- Activate, MotionSolve, and EDEM Co-Simulation

- MotionSolve can interface with Altair EDEM, a state-of-the-art bulk material simulation tool. EDEM is based on the Discrete Element Method (DEM) that simulates and analyzes the behavior of bulk materials, such as sand, granules, capsules, grass, rock masses, and so on. In this co-simulation, the mechanical part is modeled in MotionSolve and the bulk material is defined in EDEM. MotionSolve is the leading solver.

Enhancements

- Tutorial Model Files Removed from Installation Package

- To reduce the footprint size, the following tutorial model and demo

model files are no longer included in the local installation. You can

now find zipped tutorial model files and demo model files on Altair One

via the Altair Community, Altair Marketplace, and Altair Connect sites.

Altair recommends that you create an Altair One account and use it as

your primary portal to access product documentation, a Knowledge Base,

and customer support.

- Tutorial Model Files

-

- MotionSolve

Beta Features

A beta feature is one with early access due to high interest, but still can contain bugs, unfinished work, or rough edges. Please be mindful of the risk if using a beta feature.

- Active Contact Iteration (Beta)

- MotionSolve allows you to define a 2D or 3D contact force between two rigid bodies. Each body is characterized by a set of one or more geometries, which can be a 3D mesh, an analytically defined solid, or a 2D curve. Whenever any geometry on the first body penetrates any geometry on the second body, contact normal and frictional forces are generated. In this release, the rigid-to-rigid contact algorithm has been expanded with an “Active Contact Iteration” option that allows penetration to be updated during the iteration using the analytical Jacobian. This feature reduces noise in the contact forces.

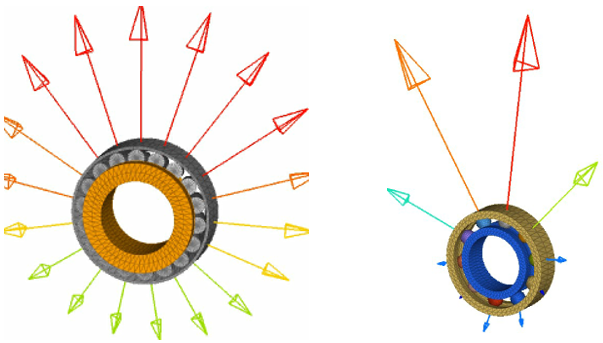

- Bearing Elements (Beta)

- Bearings are involved in almost all mechanisms, such as gearboxes, engines, robotic arms, and so on. In traditional Multibody Dynamics, bearings are often simplified by kinematic constraints, such as revolute of cylindrical joints, or by bushings. To overcome this impediment, MotionSolve was expanded with bearing components designed particularly for system analysis. In other words, they were designed to accurately replicate the non-linear compliance of bearings but are simplified enough to accommodate the need for high computational performance. The bearing components require only simple user input that can be found in many bearing catalogues. Their results can be used to study bearing loads and their life expectancy. The bearing components are developed on top of the MSolve API. They do not exist in MotionView yet. Their support in MotionView will be released in the future.

Resolved Issues

- Updated B123 that resolves some issues at singularities (~90 degree).

- Improved memory management for models, including NLFE components.

- If a body had a large initial rotation, then the system was not assembling to the correct configuration.

- Kinetic energy is reported in model units to be consistent with other results.

- OML support not available on Linux with Compose 2021.1. Use Compose 2021 instead.

- Graphics entities have an additional optional attribute called hidden for most graphics that prevents graphics from being written to the H3D.

Altair MotionSolve 2021.1 Release Notes

General

New Features

- Upgraded Intel® MKL

- MotionSolve relies on the industry-wide accepted Intel® Math Kernel Library (MKL) for its math routines. These routines are highly optimized and threaded for maximum performance. With this release, MotionSolve upgraded the version of the MKL from 2017 to 2019.5. In rare instances, this upgrade can affect MotionSolve simulation results for highly sensitive models. In other words, models that entail sources of indeterminism.

Enhancements

- MotionSolve and EDEM Co-simulation - General

- MotionSolve can interface with Altair EDEM, a state-of-the-art bulk material simulation tool. In previous versions, the integration step size in EDEM had to be an exact multiple of the communication step size between MotionSolve and EDEM. This restriction has been removed in this release. You can now select any integration step size in EDEM, providing a better user experience and potentially faster co-simulation.

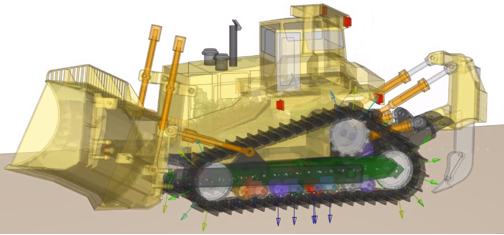

- Track Model

- In release 2021, Altair’s Multibody Dynamics products (MotionView and MotionSolve) introduced a new continuous track plug-in for tracked vehicles, such as bulldozers, excavators, robots, snowmobiles, and military vehicles. The track plug-in automatically assembles a continuous band of treads or track plates driven and suspended by two or more wheels that can interact with a soft-soil surface. In this release, the soft-soil of the track plug-in has been enhanced two-fold. First, the soft-soil can now be visualized in MotionView and HyperView for a better user experience. Second, you can choose to rigidify the soft-soil just by selecting a flag. Many track designs are being investigated on rigid grounds, such as a paved road, before they are tested on soft-soil, which made this enhancement necessary.

- Support OML-based User Subroutines

- Since release 2020.1, MotionSolve supports subroutines that are scripted in the OpenMatrix Language (OML). Initially, only an embedded OML interpreter that supports the basic OML syntax was available but did not include/support any of the additional toolboxes and libraries. In release 2021, MotionSolve was enhanced to connect with the installation of Altair Compose to interpret OML-based subroutines. This enhancement provided access to hundreds of powerful math operations and built-in functions in Altair Compose. Both features, the embedded interpreter and connection to Compose, were available only on the Windows operating system. With this release, support of OML-based user subroutines has been extended to the Linux operating system as well.

Resolved Issues

- Some multi-threaded simulations fail due to issues in the 2017 Intel Math Kernel Library (MKL). MKL has been upgraded to 2019.5.

- Solver used to ignore issues with Parasolid graphics if the graphics are used only in the post-processing. The solver can now alert you before the simulation starts if there are any issues detected with the Parasolid graphics.

- Some rotational machinery models display noisy torque values. This has been addressed by improving the Jacobian re-evaluations for torque dominating problems.

Altair MotionSolve 2021 Release Notes

General

New Features

- Track Model

- Altair’s multibody dynamic products (MotionView and MotionSolve) include a continuous track plug-in for tracked vehicles, such as bulldozers, excavators, robots, snowmobiles, and military vehicles. The track plug-in automatically assembles a continuous band of treads or track plates driven and suspended by two or more wheels, which can interact with a soft-soil surface. The user interface of the track plug-in is implemented in MotionView. MotionSolve includes all necessary elements, such as the soft-soil model and the interaction with the track links, to simulate a tracked vehicle. The track plug-in is meant to be run through MotionView only and, hence, a solver-only version is not documented.

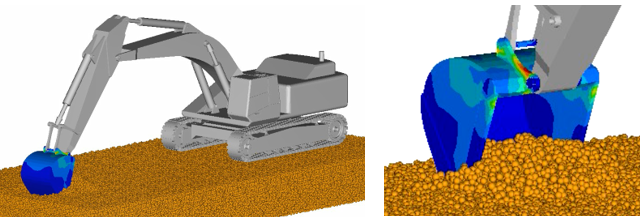

- MotionSolve and EDEM cosimulation - Flex Body Contact

- MotionSolve can interface with Altair EDEM, a state-of-the-art bulk material simulation tool. EDEM is based on the Discrete Element Method (DEM) that simulates and analyzes the behavior of bulk materials, such as sand, granules, capsules, grass, rock masses, and so on. New to this cosimulation is the capability for component model synthesis (CMS)-based flexible bodies to interact with DEM particles. CMS flexible bodies can represent body deformation in the linear range. Reaction forces due to contact between DEM particles and the flexible body are simulated, which lead to strain and stresses within the flexible body. Absolute nodal coordinate formulation (ANCF)-based non-linear finite elements (NLFEs) are not supported to interact with DEM particles at this point. This feature will be part of a future release.

- Virtualizing Joints

- In multibody dynamics, a regular, or ideal joint, can be defined as a set of algebraic constraint equations that are incorporated into the overall equations of motion. MotionSolve allows most of the regular joints to be virtualized, where the algebraic constraints are converted into a “soft”-coupling between constrained bodies. From a user’s perspective, a regular and a virtual joint provide the same kinematics and dynamics, with the exception that a virtual joint does not introduce constraint redundancy. Furthermore, virtual joints work with joint friction just as regular joints, which makes them a good replacement for bushings, where friction has to be modeled.

- Altair Compute Console

- The Altair Compute Console (ACC) utility replaces individual Start menu entries for Altair solvers (including OptiStruct, Radioss, Motion Solve, Acusolve, HyperXtrude, and several more). Use ACC to launch a solver on a local host or submit a simple job to a remote Linux server/cluster or PBS system. It includes an interactive GUI to select input files, define run options, submit multiple solver runs using a queue, schedule a delay, monitor solution progress, kill/pause a job, and execute a Fluid-Structure Interaction (FSI) solution sequence for AcuSolve with OptiStruct and Motion Solve.

Enhancements

- Support OML-based User Subroutines

- Since release 2020.1, MotionSolve supports subroutines that are scripted in the OpenMatrix Language (OML) using an embedded OML interpreter. The basic OML interpreter supports the basic OML syntax, but does not include/support any of the additional toolboxes and libraries. With this release, MotionSolve connects with the installation of Altair Compose to interpret OML-based subroutines. This provides access to hundreds of powerful math operations and built-in functions that are in Altair Compose, ranging from linear algebra, statistics, differential equations, signal processing, control systems, polynomial fitting, to optimization. If no Compose installation exist, then MotionSolve falls back to its original embedded OML interpreter. OML-based subroutines are supported on Windows only. A Linux support for OML subroutines will be provided in future releases. Due to the similarity of the OML and MATLAB scripting language, the embedded OML interpreted can be used to interpret MATLAB scripts as well, as long as the scripts do not reference any additional toolboxes and libraries. In this case, MotionSolve looks for a MathWorks’s MATLAB installation to interpret *.m files first, but if the respective interpreter is not installed, MotionSolve uses its own basic OML interpreter to run *.m scripts instead.

- Proximity Sensor

- A proximity sensor monitors the minimum separation between two bodies. The sensor tracks the state of interference of the two bodies, the minimum distance between them, and the coordinates of a pair of closest points. For this release, the computationally performance of this sensor has been improved. Furthermore, the refinement level for the graphics has been dropped from the input. Previously, only point to point distances have been calculated for meshed geometries. The new version also calculates the minimal distance between triangle/line/point combinations and thus a refinement is not needed anymore. Also, the sensor tries to use an analytical approach for primitive geometries where applicable.

- Python File Input to MotionSolve Plant in Activate

- A MotionSolve plant in Activate can accept a MotionSolve Python file as an input file. This Python file defines the model and command statements using the Python-based MSolve-API. The MDL and XML files remain as valid input files, too. Since the motion engine in InspireMotion is driven by MotionSolve, you can export a model from InspireMotion as a Python file and import it into Activate as a MotionSolve plant to run a co-simulation. Plant inputs and outputs of certain Inspire components, such as a motor, are then available within Activate to be connected to other Activate components, for example, a controller.

- MotionSolve and EDEM Co-simulation - General

- Although MotionSolve and Altair EDEM support cross-platform/multi-machine simulation, MotionSolve requires an additional EDEM installation on the same machine where MotionSolve is installed. MotionSolve uses certain binaries from EDEM for the co-simulation. For this release, the required binaries have been packaged into MotionSolve such that an EDEM installation on the same machine alongside MotionSolve is no longer required for cross-platform/multi-machine co-simulation.

- MotionSolve and OptiStruct Co-simulation - General

- MotionSolve has the ability to interface with OptiStruct. You can define flexible bodies that undergo plastic deformation or contact with other flexible bodies in OptiStruct, and connect these bodies with larger mechanical systems in MotionSolve via interface nodes (spherical joints). In this release, a new stabilization algorithm has been introduced at the interface nodes between MotionSolve and OptiStruct that allows for larger timesteps and a more robust cosimulation experience. The co-simulation is currently available in MotionView as an experimental feature only. To activate this feature, set the environment variable HW_MV_EXPERIMENTAL=OSFLEX.

- Descriptor State Space

- MotionSolve is able to generate matrices for state-space representation during a linear analysis step. The respective matrices (A, B, C, D) describe a mathematical model of a physical system as a set of input, output, and state variables related by first-order differential equations. Until now, MotionSolve only supported forces as inputs for state-space generation. Since release 2020.1, you can define motion as inputs as well, which will result in a linear implicit model. The motions are added as algebraic constraints, which leads to a descriptor state-space representation on the form of Eẋ = Ax + Bu and y = Cx + Du, where x is the state vector, u is the input vector, and y is the output vector. Descriptor State Space is currently supported in MotionSolve through .xml input files or the Msolve API; it is not available through MotionView. With this release, smaller enhancements to the descriptor state-space has been provided for a more robust analysis.

- PSTATE for Linear Analysis

- Reference_PlantState contains a list of VARIABLES that have been defined in the model. These VARIABLES define the states to use in the linearization. MotionSolve uses these states for generating the linear problem. Reference_PlantState is currently supported in MotionSolve through .xml input files or the MSolve API only. MotionView will support this feature in a future release. With this release, smaller enhancements to PSTATE have been accomplished that make the attribute numerical_Jacobian obsolete in the Parameters: Linear Solver statement.

Resolved Issues

- Linear analysis neglected higher order dynamic effect in certain instances. The exact linearization of the Equation’s of Motion are now used instead of an approximation.

- Linear analysis provided the wrong results if field forces were directly attached to CMS-based flexible bodies.