Tutorial 18: Variable Definition Tutorial

Purpose/Objective

This exercise will walk the user through building a simple tube & orifice model with the use of variable definition. The user will learn how to:

- Create Chamber & Element

- Create Variable & Set Expression

- Define Element Properties via Variable

- Check the model

- Run the model & Post-Process

- Creation of Multi-Case

- Creation of Derived Result Variable

- Post-process of Multi-Case run

- Chamber Types: Plenum, Momentum

- Element Types: Conventional Orifice, Tube

- Fluid: Air

Step 1: Create Chamber & Element

- The user will be creating a flow model consists of simple tube and orifice element where tube radius is known.

- Plan model setup based on what is known about the geometry

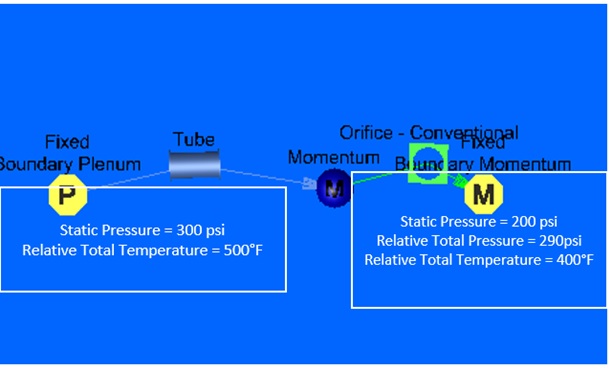

Figure 1.01: Sketch/Outline of model

- Drag and drop Boundary Plenum & Boundary Momentum chambers at the inlet and

outlet locations as shown Figure 1.01

- Translate (right click chamber/element → translate) option and manually editing the coordinates (Property Editor → Location), can be used to assist in placing chambers and elements in the right location

- Use

to adjust symbol and text size

to adjust symbol and text size - Place non-boundary momentum chambers at the center location.

- Connect stationary tube element between boundary plenum (left) and the center momentum chamber, and conventional orifice element between center momentum chamber and boundary momentum (right) chamber.

- For the inlet boundary plenum

- Set pressure to 300 psi

- Set temperature to 500 F

- For the sink boundary momentum

- Set static pressure to 200 psi

- Set total pressure to 290 psi

- Set temperature to 400 F

- For the outlet conventional orifice

- Set area to 0.25 in^2

- Set Cd to 0.8

Step 2: Create Variable and Expressions

- Creation of Variable

- Click

to open Variable

Edit Tree or the steps described in quick guide

to open Variable

Edit Tree or the steps described in quick guide - Create Variable named “Radius” and set a constant value of 0.25

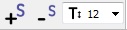

- Create another variable named “Area” and set expression as

“Math.pow([Radius],2) *Math.PI” in secondary pop-up window as shown in

the following figure. Make sure to click “Execute” button after

defining.

Figure

1.02

Figure

1.02

- Click

Step 3: Define Element properties via Variable

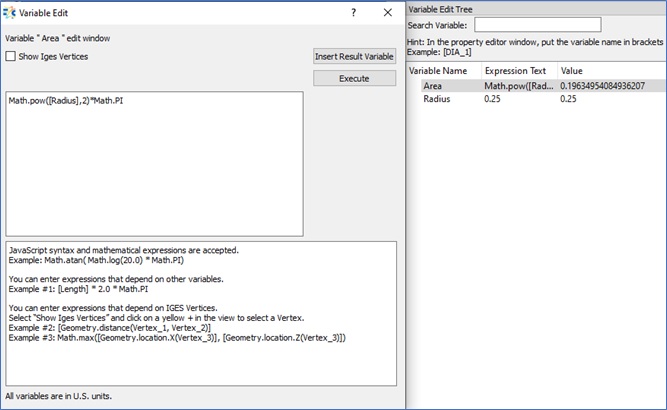

- For the Tube Element

- Set Geometric Input Type as “Area” only

- Set Geometric Input size as “Constant” only

- Set Area as “[Area]”, which is a defined variable, as shown Figure 1.03

- Set Length as 5 in.

Figure 1.03

Step 4: Check Model and Run

- Select checkmark icon from the top toolbar

to check the model for warnings/errors.

to check the model for warnings/errors.- An error should populate stating that the internal chamber has not been initialized

- Select the initialization icon from the toolbar

, and pick Start. Accept values once flow

solver has converged.

, and pick Start. Accept values once flow

solver has converged. - Select run icon from toolbar

. Run Flow Simulator.

. Run Flow Simulator.

Step 5: Post-process

- Results file (*.res) should automatically be loaded into GUI. If not, it can be selected via File → Load Result File

- By default, both chamber and elemental results are displayed in the graphical

workspace.

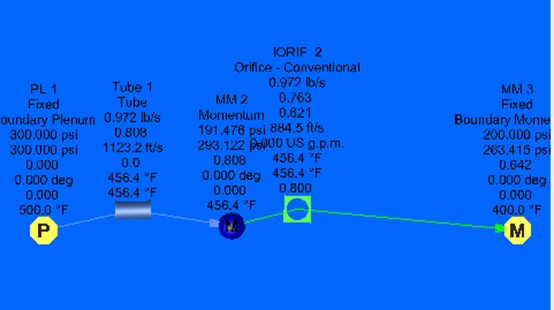

Figure 1.04: Model results

- Results displayed after running the model will include pressures, temperatures, and swirl values

Step 6: Creation of Multi-Case & Run

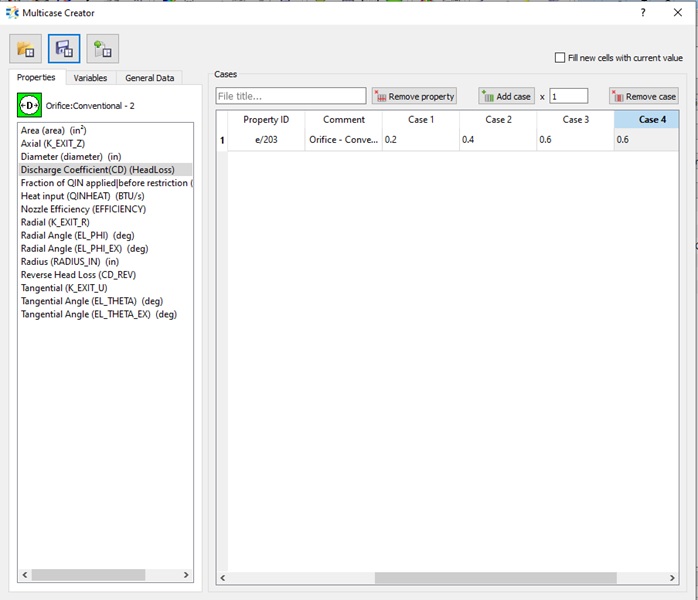

- In this section a multicase will be created using MultiCase Creator Tool with 4 case where in each case Cd values of the orifice element will be varied (0.2, 0.4, 0.6 & 0.8).

- Click

to open Multicase Creator Graphical User

Interface.

to open Multicase Creator Graphical User

Interface. - Click “Properties” tab on left side of the GUI Window.

- Select Orifice element from main Graphic window, when selected the properties related to the element will be populated in left side of the Multicase Creator GUI

- Select “Discharge Coefficient(CD) (HeadLoss)” from the list of items.

- Click

4 times to add 4 columns in left

side of the table.

4 times to add 4 columns in left

side of the table. - Enter 0.2, 0.4, 0.6 & 0.8 for Case 1 , Case 2, Case 3 & Case 4 column.

- Save the multi-case by clicking

in top left corner of the Multicase Creator

GUI.

in top left corner of the Multicase Creator

GUI.

Figure 1.05: Multi-Case Creator

- Select the initialization icon from the toolbar

, and pick Start. Accept values once flow

solver has converged.

, and pick Start. Accept values once flow

solver has converged. - Select run icon from toolbar

.

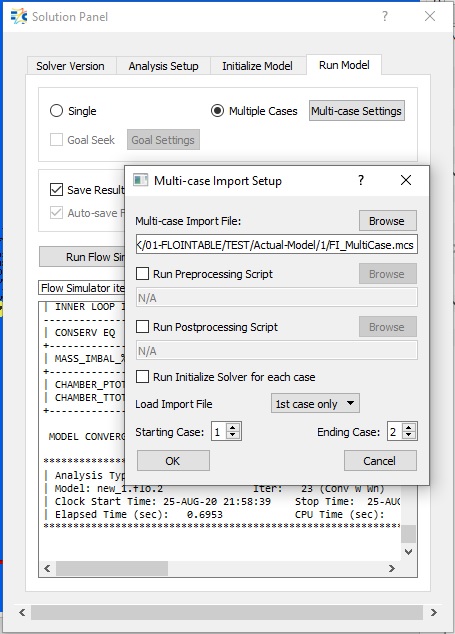

. - Choose “Multiple Cases” and click “Multi-Case Settings” button to make sure proper multicase import file is selected.

- Check “Save Results to separate Folder” and then Run Flow Simulator

Figure 1.06: Run option during Multi-Case

Step 7: Creation of Derived Result Variable

- In this section a result variable will be created using Variable Edit Tool

- Open Variable Edit Tree by clicking

button.

button. - Create a new variable named “Dynamic-Head”. Right-Click and then “Set Expression” to

define the expression for this newly created variable.

- Click “Insert Result Variable” button.

- Select “Chamber”.

- Select “Entity” from drop-down list.

- “Select “Total Pressure” from the populated list.

- Click “Insert Expression”.

- Enter “-” (negative sign) inside the expression box.

- Repeat process (i-v) to insert static pressure. After the expression should looks like as shown in figure 1.07.

- Click Execute.

Figure 1.07: Defining Derived result variable

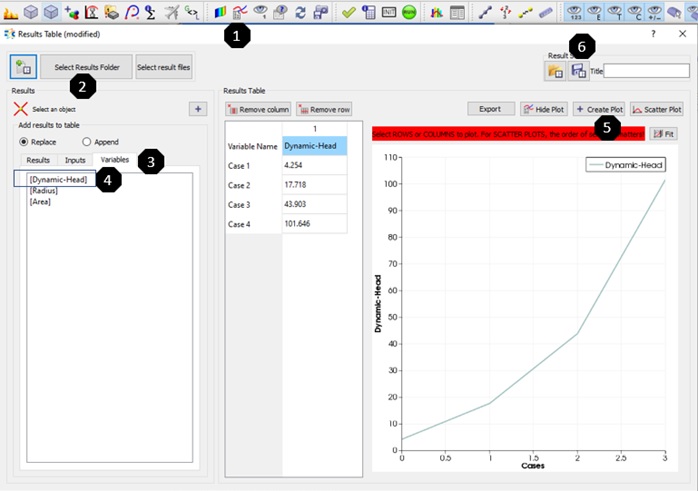

Step 8: Post-Process Multi-case Result using Result Table

- This section will provide details on how to post-process multi-case results with one

derived result variable

- Open “Result Table” pop-up GUI by clicking

button.

button. - Click “Select Result Folder” to choose the multi-case result folder.

- Click “Variable” Tab under which all defined variables are listed.

- Choose “Dynamics-Head”. The “Dynamic-Head” data of all 4 cases will be displayed in right window as shown in the figure 1.08.

- User can create plot using

option

option - At last user can save the result set by clicking

button.

button.

Figure 1.08: Defining Derived result variable

- Open “Result Table” pop-up GUI by clicking