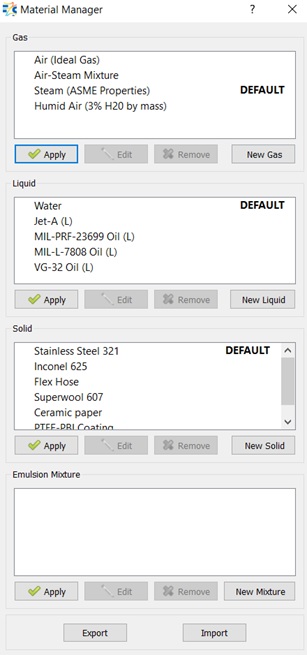

Material Manager

Flow Simulator provides convenience to the users through Material Manager option. Users can define a default material for their models either by selecting from the predefined lists or by creating their materials. Thus, they do not need to select material through Property Editor.

All the materials in the Material Manager can be defined as DEFAULT, can be edited and removed through “Apply”, “Edit”, and “Remove”.

How to Set a Material as Default

Materials are grouped under 4 types: Gas, Liquid, Solid and Emulsion Mixture. If the default material is listed under any of these groups, users can click on the name of the material and “DEFAULT” will be selected.

How to Define New Material in Gas, Liquid or Solid Phase

If the default material is not in the list, users can create the material through New Gas if the material is gas, New Liquid if the material is liquid, New Solid if the material is solid and New Mixture if the material is emulsion mixture.

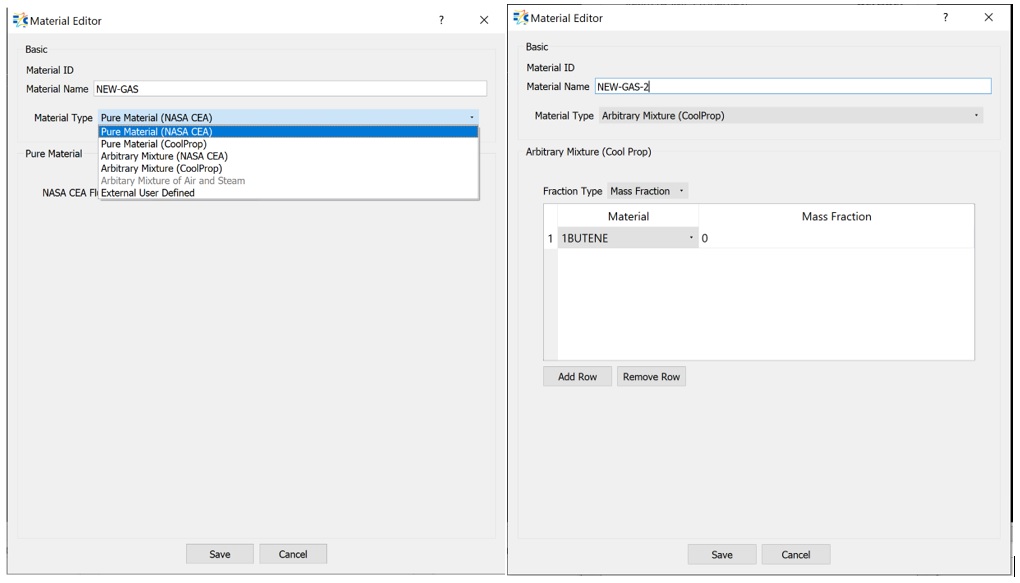

On the Material Editor window, users should provide a name for the new material.

At the New Gas and New Liquid menus many materials are listed under the headings;

- Pure Material (NASA CEA):

- Pure Material (CoolProp):

- Arbitrary Mixture (NASA CEA):

- Arbitrary Mixture (CoolProp)

And, users can select one of these materials, and all fluid and thermal properties, i.e density, viscosity, specific heat, conductivity, etc. will be used either from NASA CEA database or from CoolProp database based on user selection.

If, Arbitrary Mixture is selected, then user should provide Mass Fraction or Mole Fraction

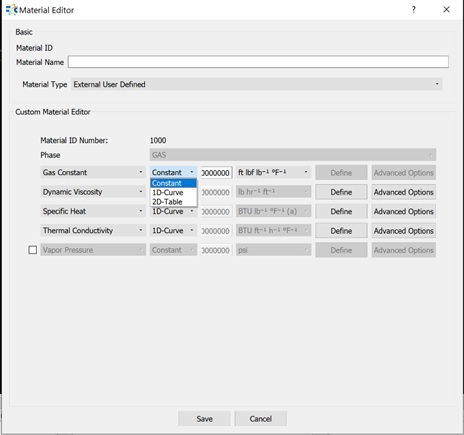

“External User Defined” option enables users to define their own material by providing all required fluid properties. Material ID starts with 1000 for External User Defined materials, and both the ID and the given name are printed in .flo file. Thus, users can distinguish the user defined materials in the file.

The properties that are requested from users are:

| GAS PHASE | LIQUID PHASE | SOLID |

| Gas Constant or Density | Density | (*) Density |

| Dynamic Viscosity | Dynamic Viscosity | (*) Specific Heat |

| Specific Heat or Specific Heats Ratio | Specific Heat or Specific Heats Ratio | Thermal Conductivity |

| Thermal Conductivity or Prandtl Number | Thermal Conductivity or Prandtl Number | (*) Surface Emissivity |

| (*) Vapor Pressure or Boiling Condensation Point | (*) Vapor Pressure or Boiling Condensation Point | (*) Melting/Freezing Point |

| (*) Melting/Freezing Point | ||

| (*) these properties are not “must”, users should enable when they want to use in their analysis. | ||

There are 3 available options to provide materials’ property.

- Constant: A constant value can be provided for the property with its

value and unit.

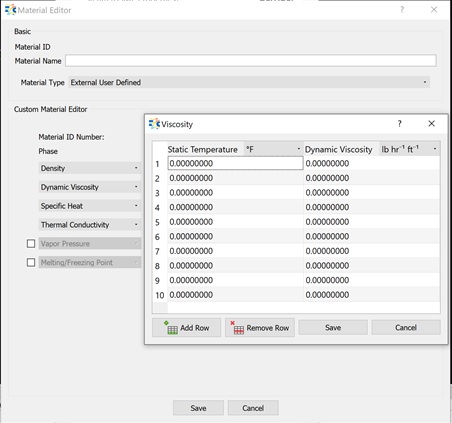

- 1D-Curve: Static Temperature vs “Selected Property” table should be

provided by clicking Define.

Note: Users can add or remove rows from Add Row and Remove Row respectively.

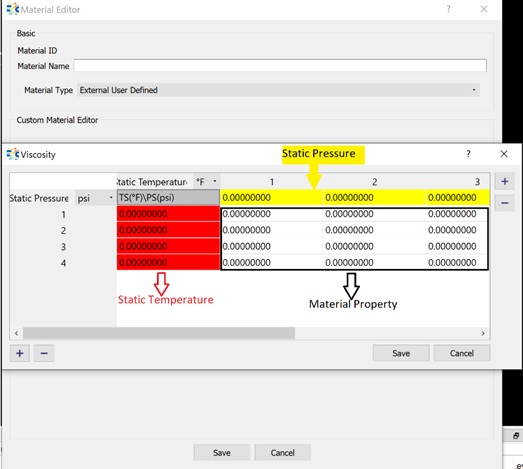

Note: Users can add or remove rows from Add Row and Remove Row respectively. - 2D-Table: Static Pressure vs Static Temperature vs “Selected Property”

should be provided in the table shown below

Temperatures should be given in the RED COLUMN, Pressure values should be written on the YELLOW ROWS, and property values should be filled in the table.

Note: Users can add/remove rows and columns by clicking on PLUS/MINUS signs at the left bottom corner and right top corner, respectively.Moreover, under Advanced Options, users can select options to transform and/or interpolate the provided values.

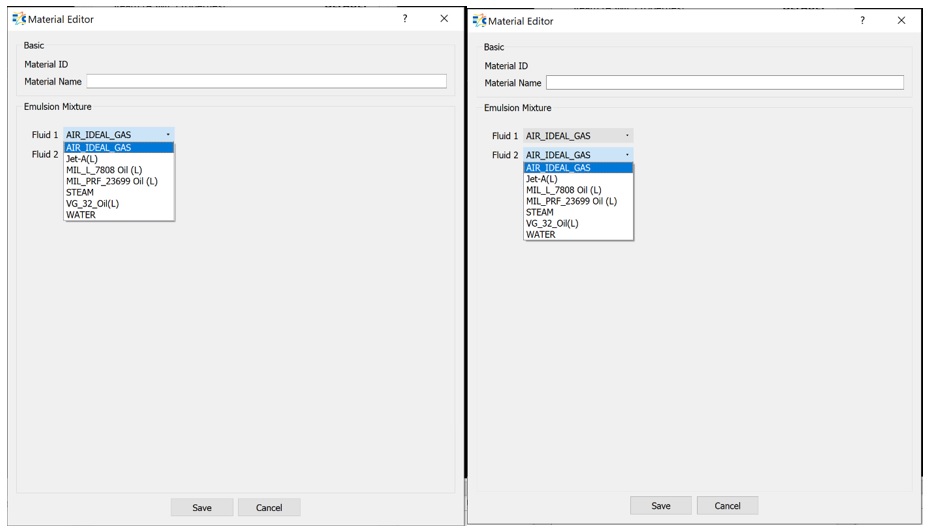

How to Define New Mixture

Users can define new mixtures as working fluid in their models by selecting Fluid 1 and Fluid 2 under New Mixture option.

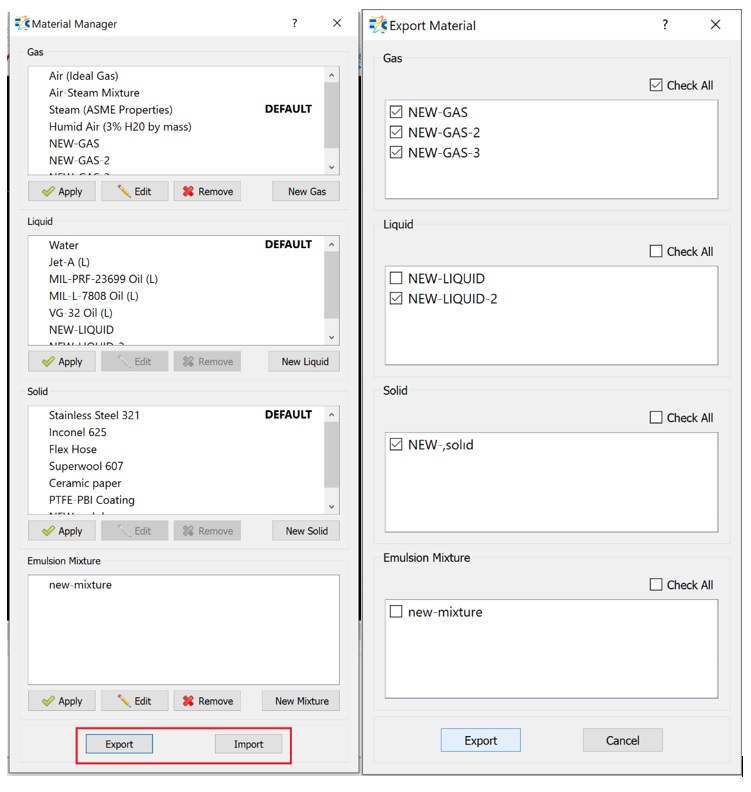

Import/Export Material Property

In Flow Simulator, it is possible to import and export the material properties in JSON format.

Check All: Exports all the materials under that phase.