View Print3D Results

View, animate, and plot the results of a 3D printing analysis.

- To change the legend color for the result type, click the icon next to the results slider and select Legend Colors.

- To delete a run from the Analysis Explorer, right-click the run name to select Delete Run from the context menu.

Result Types for Print3D

3D printing analysis produces results for displacement, plastic strain, von Mises stress, nodal temperature, and temperature.

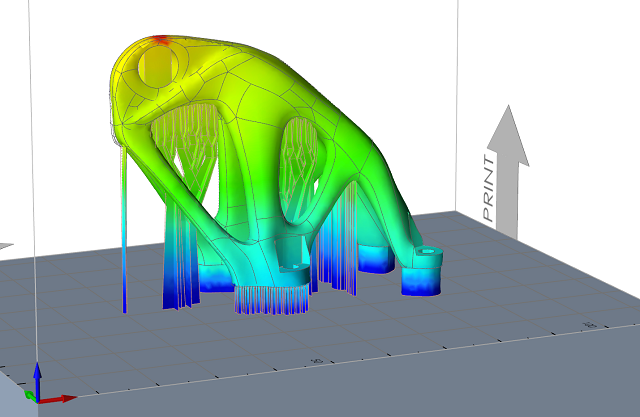

Displacement

The displacement result type shows how much your model will displace or deflect during the 3D printing process. The areas of the model that are the darkest orange will have the most displacement.

When reviewing displacement results, you should check that the order of magnitude of the displacement and the shape of the deformation make sense. Use the Animation tools on the Analysis Explorer to view the shape of the deformation.

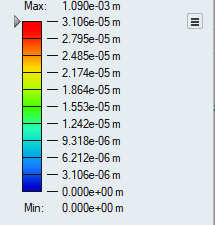

Plastic Strain

Plastic strain result type shows which parts have exceed their yield limit and begun to deform. The dark orange areas show the areas under the greatest strain.

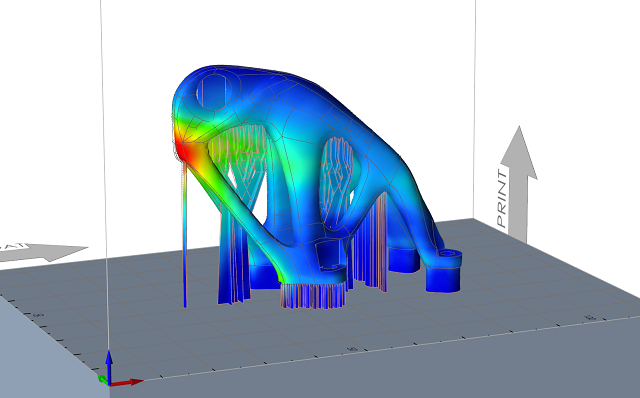

von Mises Stress

The von Mises stress results can be used to predict part performance and durability. Areas shown in orange/red have exceeded the peak stress.

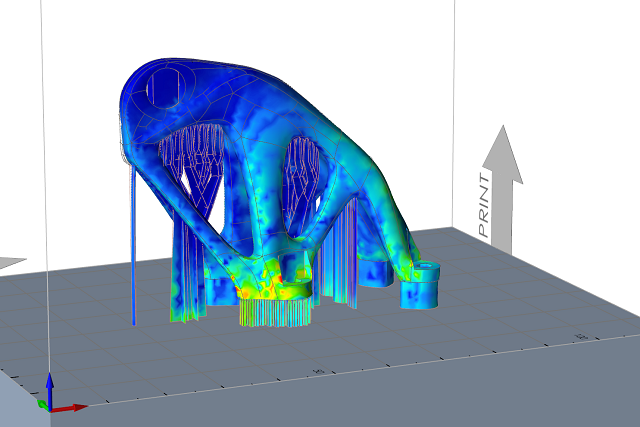

Nodal Temperature

This result type shows the actual temperature on a particular node. The highest temperatures are shown in red and the coolest temperatures in blue. Nodal temperatures may be more extreme than the average element temperature.

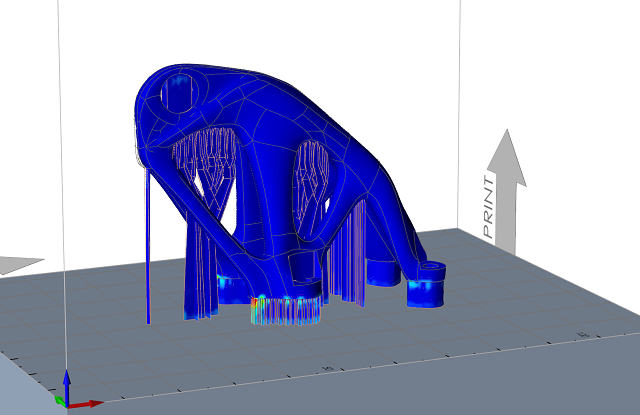

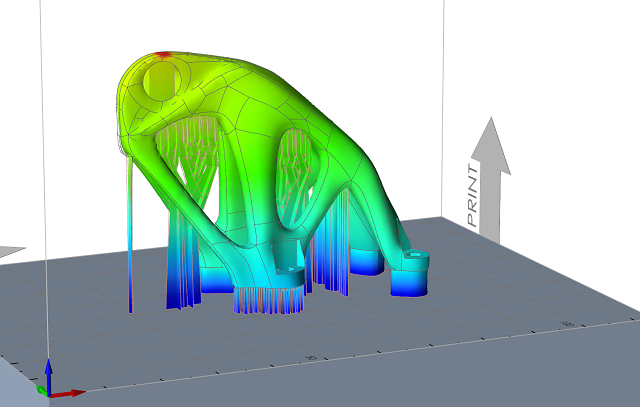

Temperature

This result type shows which areas on the part have the highest temperature (red/orange) vs. the coolest temperature (blue/green) after the printing process is completed. The temperatures are calculated as an average for each element, as opposed to the nodal temperature.