RD-V: 0200 Hardening Modulus

The plastic hardening modulus is evaluated in a Johnson-Cook material.

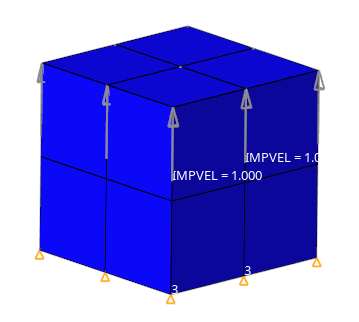

Figure 1.

The /MAT/LAW2 (PLAS_JOHNS) material model is used to study the plastic hardening modulus of a material.

Options and Keywords Used

/MAT/LAW2 (PLAS_JOHNS)

Input Files

The following input file is used in this verification problem:

<install_directory>/hwsolvers/demos/radioss/verification</material/0200_hardening/

Model Description

A tensile loading is applied to a cube with side lengths 25.4 mm. The bottom of the cube is fixed in the z-direction and an imposed velocity of 508 mm/s in the z direction is applied to the top of the block. The simulation was run to a final time of 0.05 seconds. A two elements per side mesh was studied.

The plastic hardening modulus, H, is used as the problem metric. In Radioss, the plastic hardening parameter, b, in /MAT/LAW2 (PLAS_JOHNS) material law is the same as the plastic hardening modulus, H.

The following system is used: mm, s, Mg.

Results

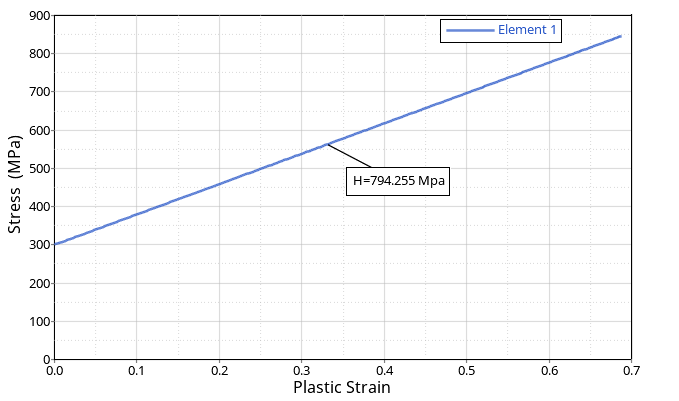

The plastic hardening modulus is the slope of the stress versus plastic strain curve.

Figure 2. Stress versus Plastic Strain with Hardening Modulus

Conclusion

As shown in Figure 2, the hardening modulus from the simulation, H=794.225 Mpa, exactly matches the value input for “b” in /MAT/LAW2 (PLAS_JOHNS).