Midmeshing

Automatically generate a mesh at the midplane location, directly from the input geometry (components, elements, solids or surfaces), without first creating a midsurface.

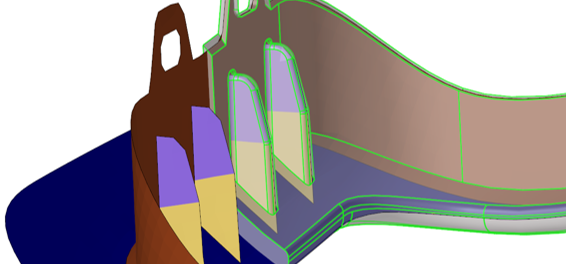

Figure 1. Midmesh Result Example

The resulting output consists of 2D shell elements created with the user-provided target size, as well as 1D elements defining the topology of the mesh (vertices/edges/faces). Midmesh generation is also multithreaded to take advantage of multi-core environments.

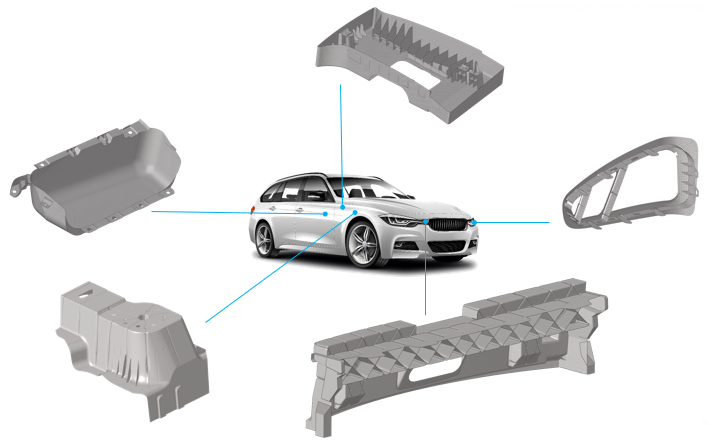

Direct Midmesh Supported Parts

Figure 2. Direct Midmesh Supported Parts

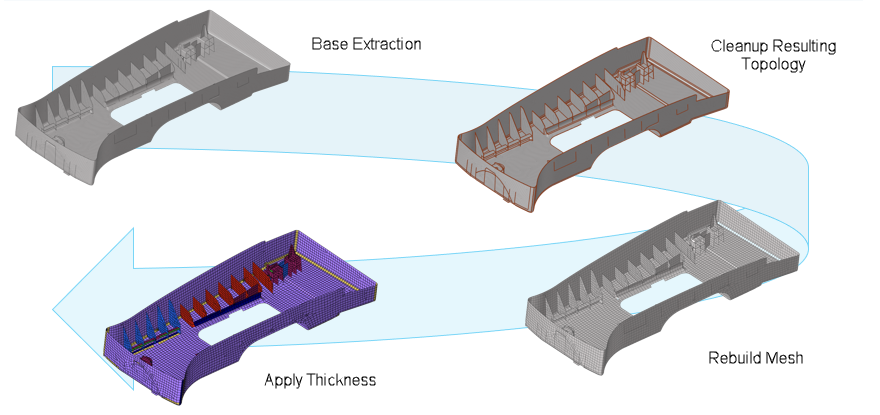

Midmesh Generation Workflow

- Base Extraction

- Extract the base midmesh.

- Cleanup Resulting Topology

- Use the semi-automated midmesh editing tools to correct the 1D topology and fix any bad/missing faces. The goal is to prepare the model for final remeshing.

- Rebuild Mesh

- Remesh to the final flow and quality using the rebuild mesh functionality, and correct any remaining mesh quality issues.

- Apply Thickness

- Map the thickness from the original solid to the midmesh via the Map Thickness tool.

Figure 3. Midmesh Workflow