Result Types

Results are available for filling, packing, cooling, and warpage analysis stages.

Filling Results

| Option | Description |

|---|---|

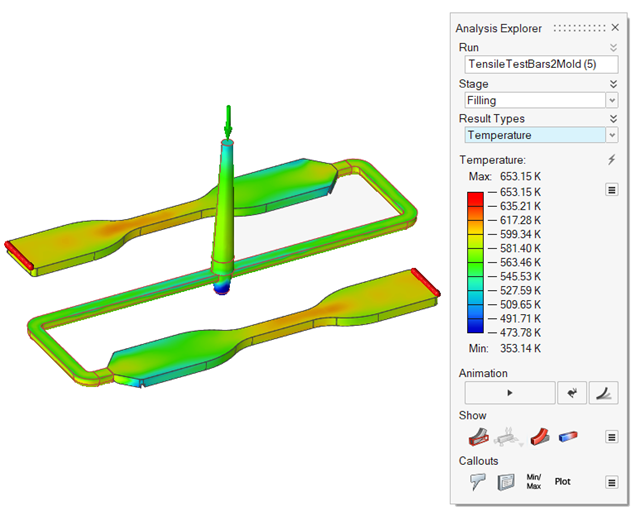

| Temperature |

|

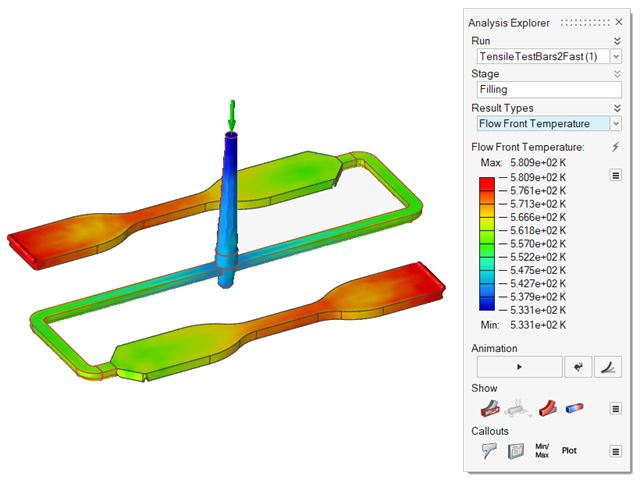

| Flow Front Temperature | Review the temperature at the time of filling. |

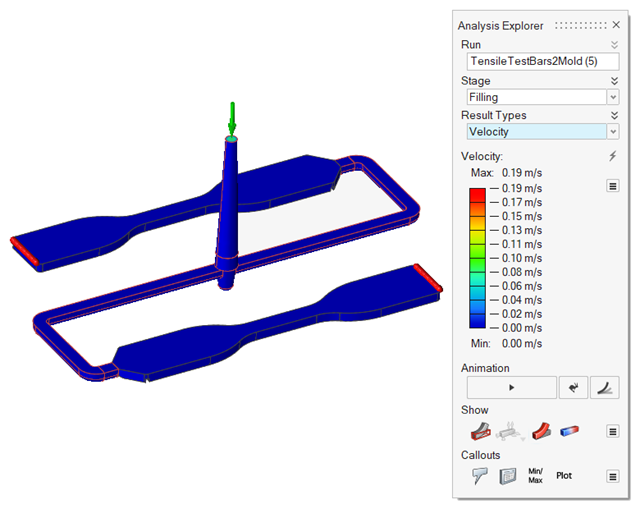

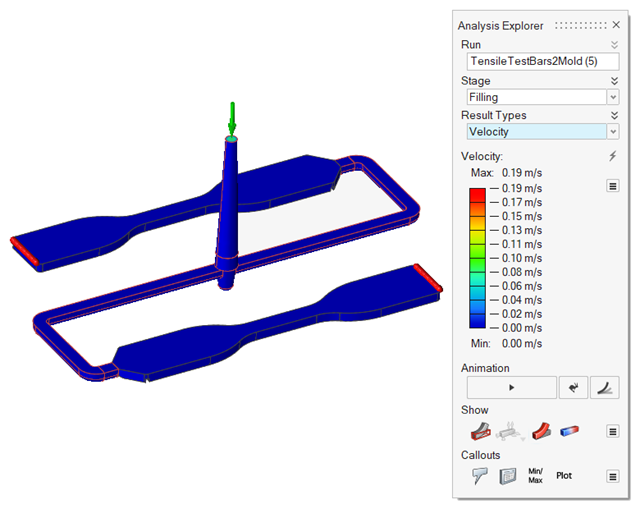

| Velocity |

|

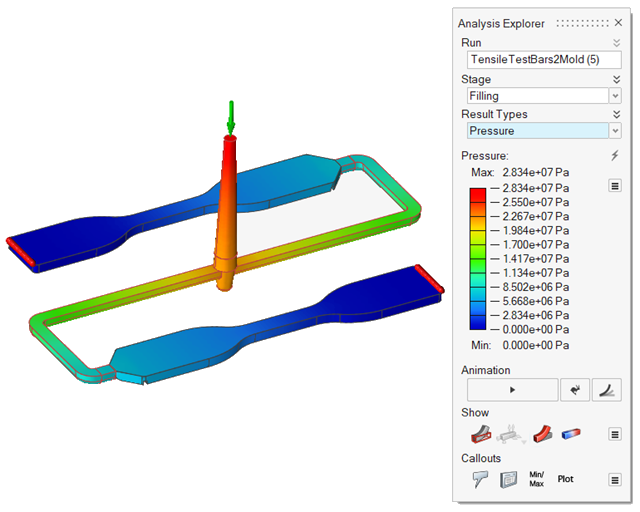

| Pressure | Review pressures inside the mold cavity produced during the

filling stage. |

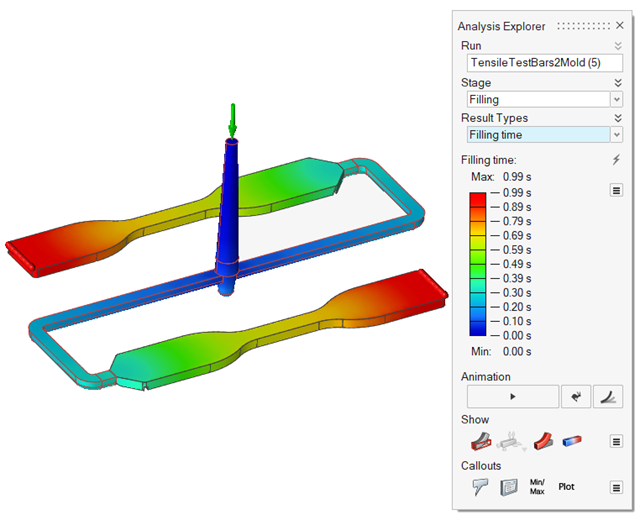

| Filling Time | Review the time it takes the material to reach different

areas within the part. The filling results can help you

determine the best way to fill the part and detect patterns that

indicate the potential for incomplete filling, unbalanced flow,

weld lines and air pockets. |

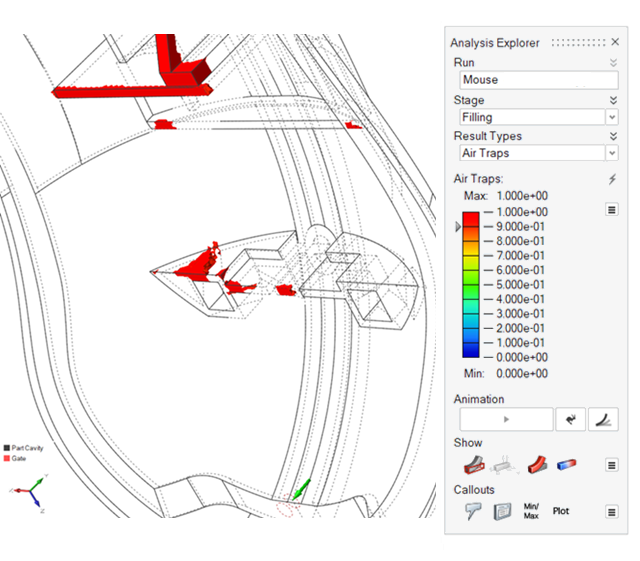

| Air Traps |

|

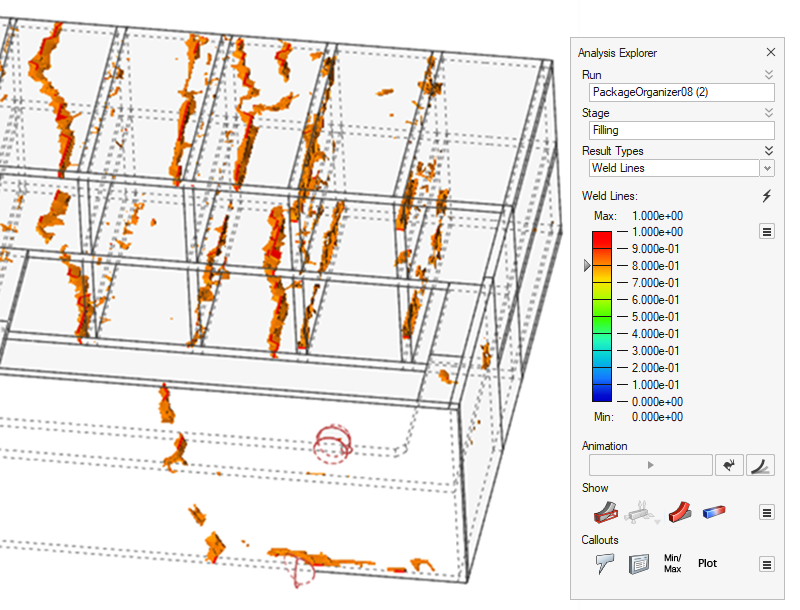

| Weld Lines | Locate regions during filling where two flow fronts meet.

Such regions may cause structural and cosmetic issues. |

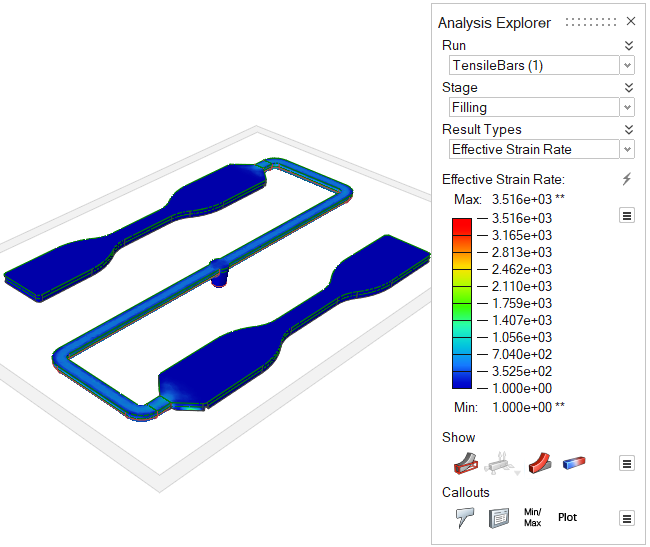

| Effective Strain Rate | Review the polymer's effective strain rate. The polymer's

viscosity is a strong function of its strain rate. This result

can help you understand the filling behavior of the polymer.

Additionally, if strain rate exceeds a certain threshold

(different for each material) the polymer may degrade.  |

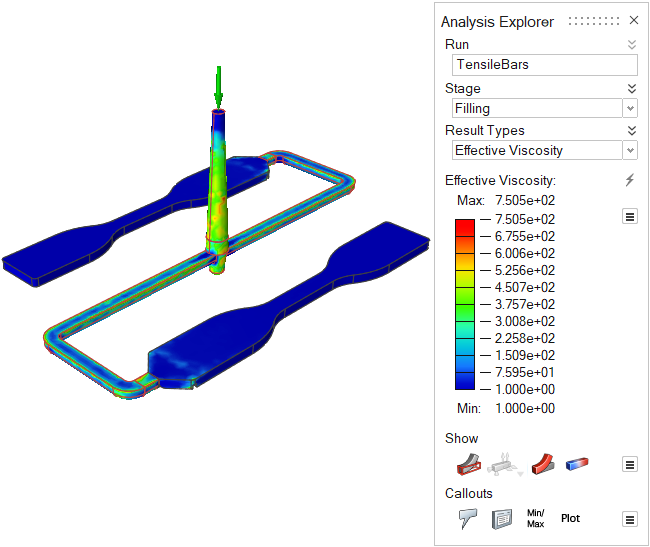

| Effective Viscosity | Review the polymer's effective viscosity over time. Effective

viscosity is a function of temperature and strain rate, and

directly affects the material's flow behavior. This result can

help you design gate regions for optimal filling.  |

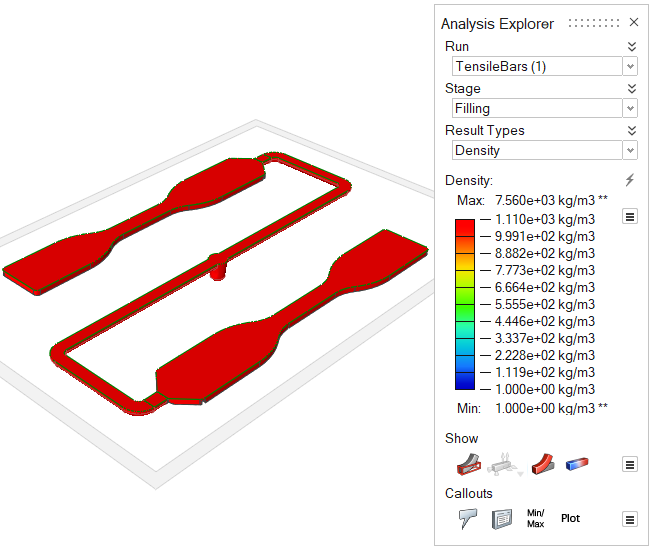

| Density | Review the polymer's density over time. Uniform density is

ideal for high quality results. |

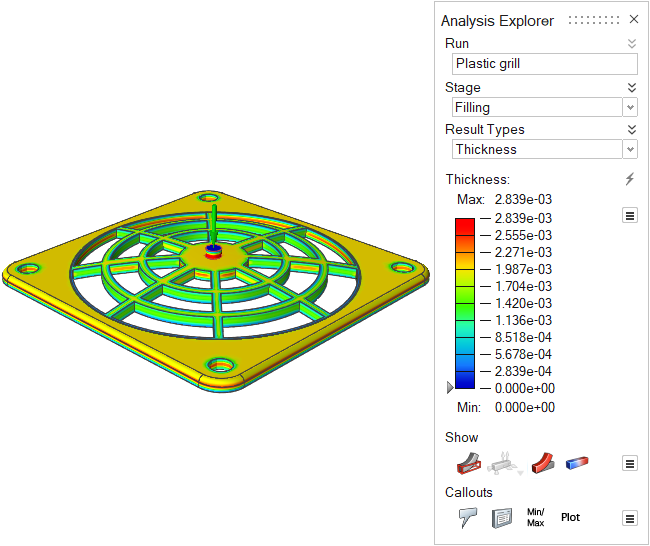

| Thickness | Review the thickness of different areas of the part. Local

part thickness affects local strain rates and heat flow. Abrupt

changes in thickness cause uneven cooling, which can lead to

part shrinkage and defects such as sink marks in the final part.

This result can give insight into the entire process. |

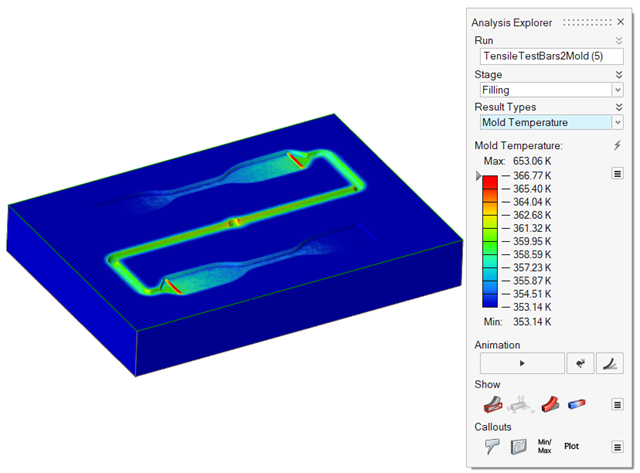

| Mold Temperature | Review temperature variances in the mold. |

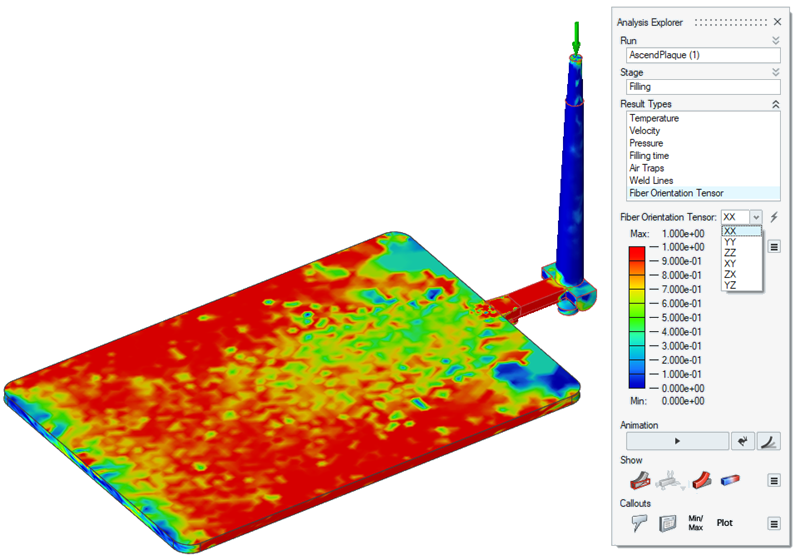

| Fiber Orientation Tensor | Review diagonal and cross products results for the tensors.

The result predicts the fiber orientation tensor for short fiber

reinforced polymers.

|

Packing Results

| Option | Description |

|---|---|

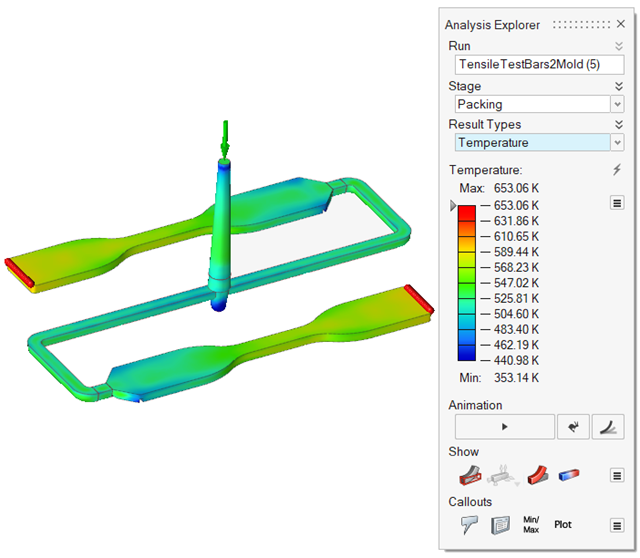

| Temperature | Review temperatures during the packing phase. The temperature

will decrease due to the temperature loss across the mold

walls. |

| Velocity | Examine velocity during the packing phase. Velocities will

decrease until the fluid stops flowing. |

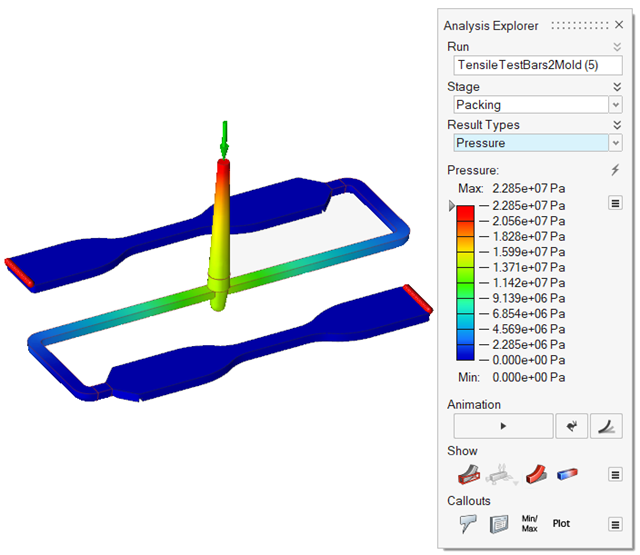

| Pressure | Consider pressures during the packing phase. These results

are useful to know points where the pressure is less than 0 to

detect areas prone to suffer a sink mark defect. |

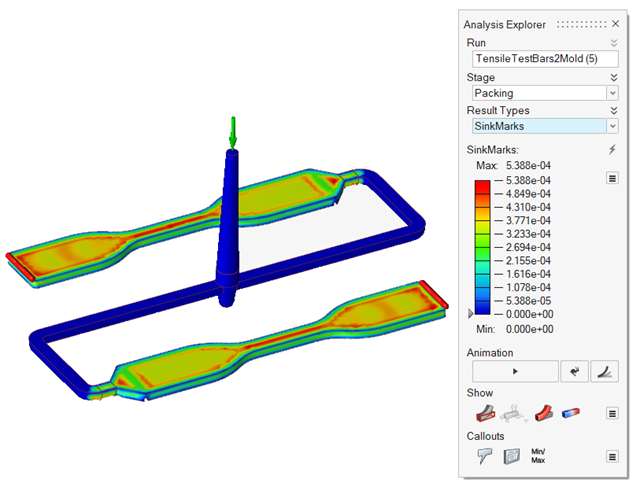

| Sink Marks | Detect surface depressions, usually in the thicker sections

of the model, caused by shrinkage during the packing

stage. |

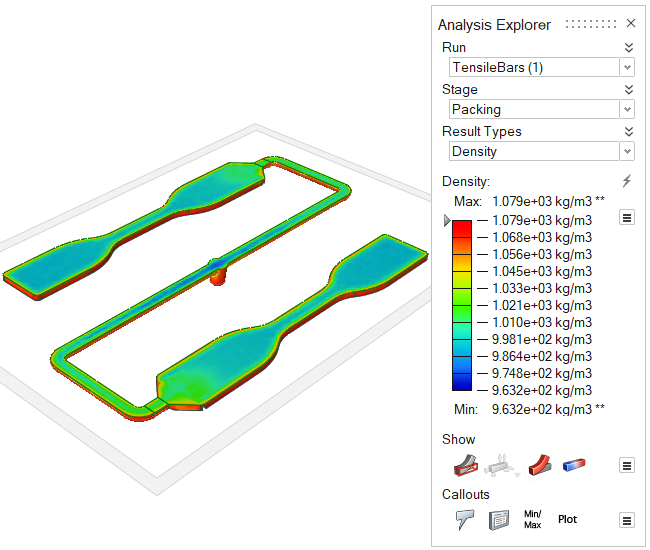

| Density | Review changes in the polymer's density over time. Uniform

density is ideal for high quality results. This result can help

pinpoint the causes of such defects as sink marks and

shrinkage. |

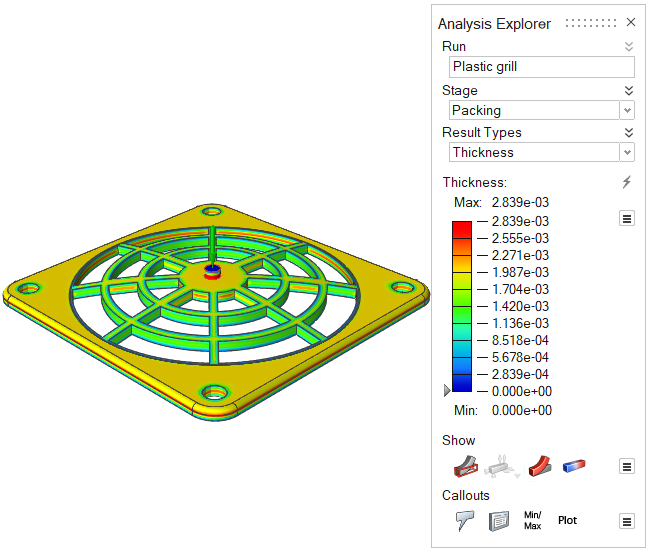

| Thickness | Review the thickness of different areas of the part. Local

part thickness affects local strain rates and heat flow. Abrupt

changes in thickness cause uneven cooling, which can lead to

part shrinkage and defects such as sink marks in the final

part. This result can give insight into the entire

process. |

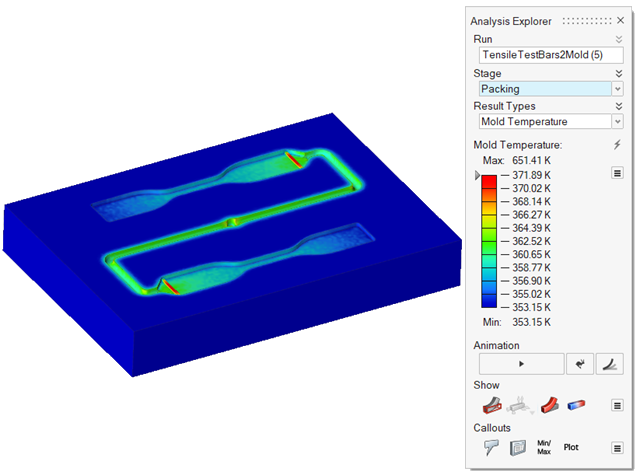

| Mold Temperature | Review temperature variances in the mold. |

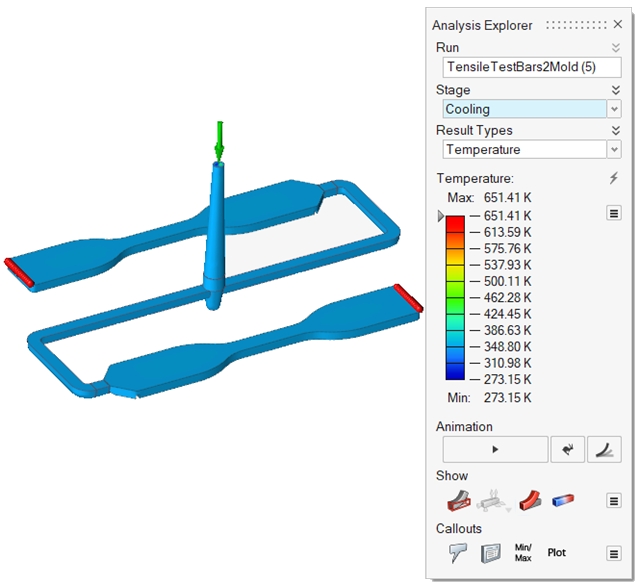

Cooling Results

| Option | Description |

|---|---|

| Temperature | Examine the temperature evolution once the mold is totally

filled. You can determine the final temperature at which to stop

the cooling phase. |

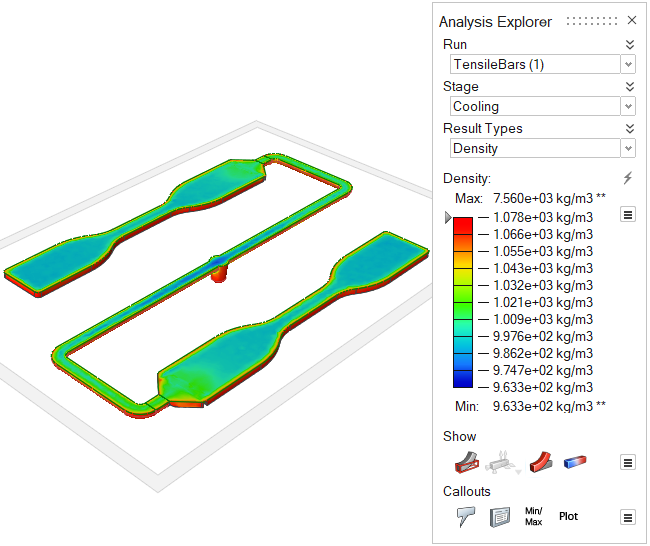

| Density | Review changes in the polymer's density over time. Uniform

density is ideal for high quality results. This result can help

pinpoint the causes of such defects as sink marks and shrinkage.

|

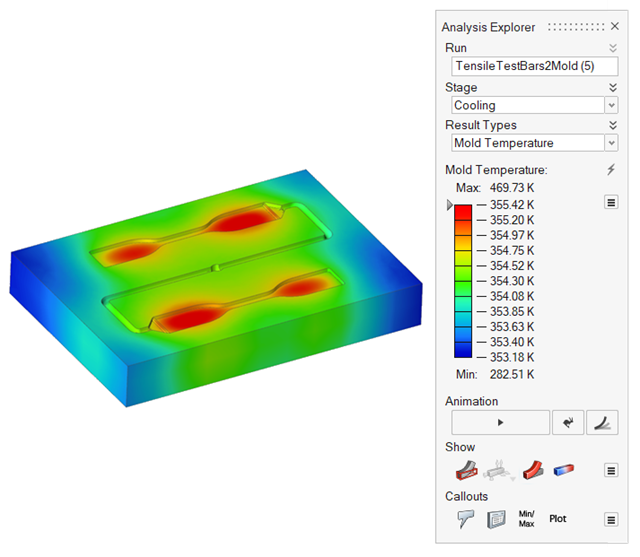

| Mold Temperature | Review temperature variances in the mold. |

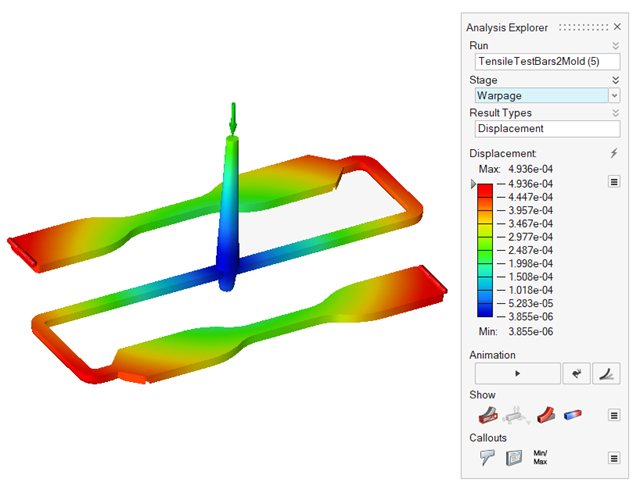

Warpage Results

| Option | Description |

|---|---|

| Displacement | Detect folding, bending, twisting or bowing in the molded

part, which is usually due to non-uniform cooling. The

displacement contour displays how the part is warping so that

you can make the appropriate corrective measures to the cooling

rate, cooling channel design, or process data. |