MV-7021: MotionSolve/EDEM Co-Simulation

In this tutorial, you will learn about the set-up and co-simulation of MotionSolve and EDEM through MotionView.

MotionSolve has the ability to interface with Altair EDEM, a state-of-the-art bulk material simulation tool. EDEM is based on the Discrete Element Method (DEM) that simulates and analyzes the behavior of bulk materials such as sand, granules, capsules, grass, rock masses etc. For more information about this method refer to www.edemsimulation.com and the Discrete Element Simulation in MotionSolve topic in the MotionSolve User Guide.

This tutorial assumes minimum knowledge in both Altair’s MotionSolve/MotionView and EDEM.

- Requirements

- The following pre-requisites are necessary for a successful interaction

between MotionSolve and EDEM:

Software Version HyperWorks 2019.1 or later for rigid body coupling 2021 or later for flexible body coupling

EDEM 2019.1 or later for rigid body coupling 2020.3.1 or later for flexible body coupling

- Problem Definition

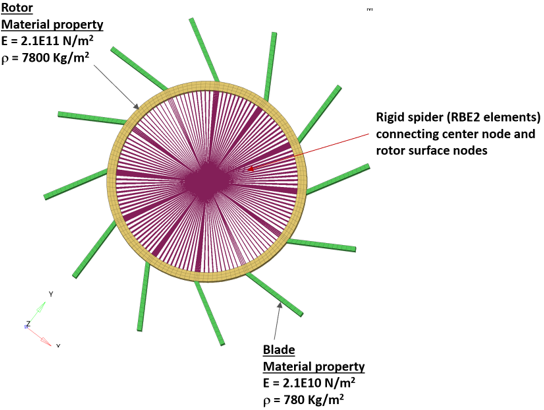

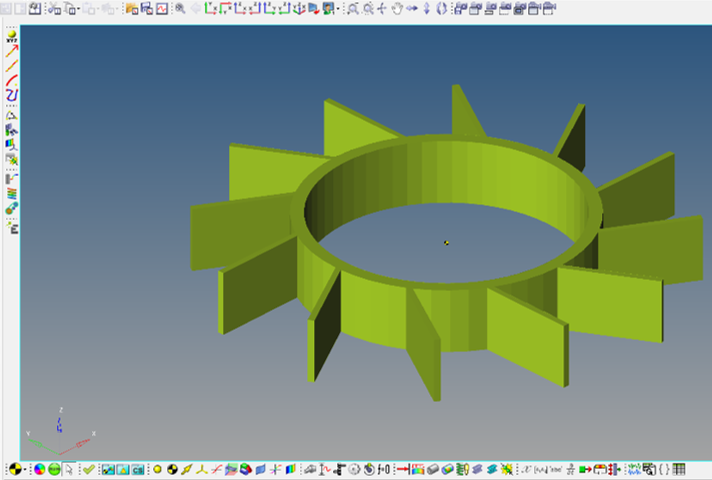

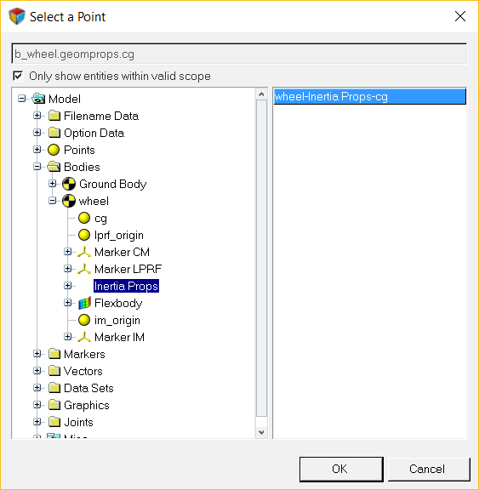

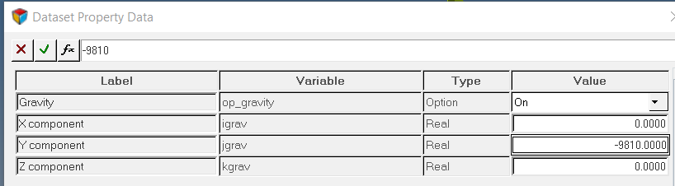

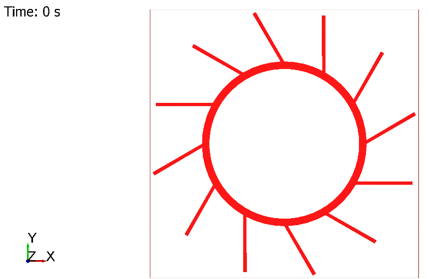

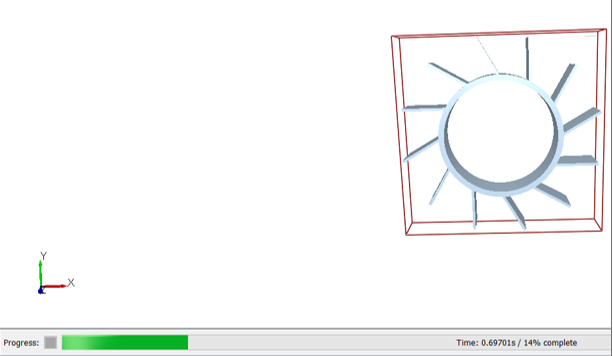

- The problem consists of a wheel, that can only rotate around its center. A number of particles is impinged on the wheel blades, causing it to rotate. The wheel is modeled in MotionSolve, while the particles and its interaction with the wheel is modeled in EDEM. A rigid Wheel to particle interaction is set up first. The wheel is later replaced with a flexible body to show flexible body to particle interaction.

Set Up the Motion Model

Set Up the EDEM Model

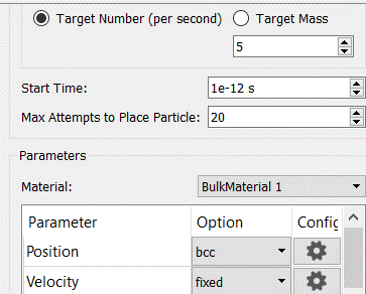

- Define a bulk material

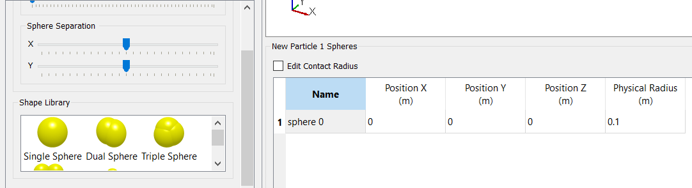

- Define a particle shape

- Define an equipment material

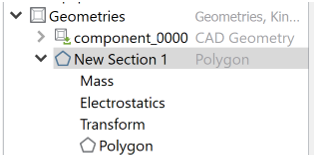

- Define the equipment geometry

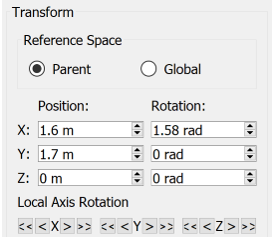

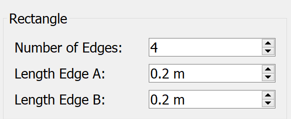

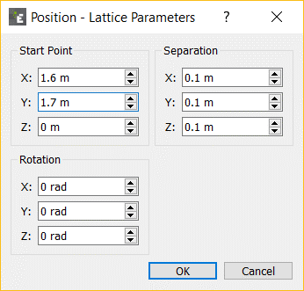

- Define a virtual geometry/particle factory

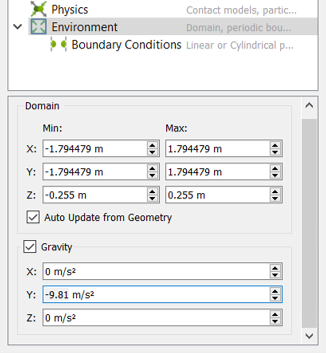

- Define environment parameters

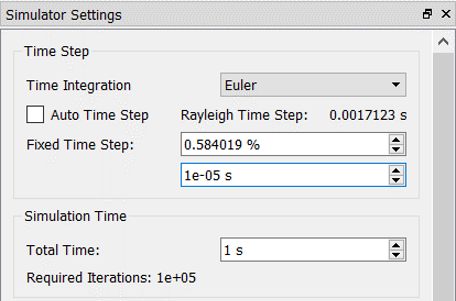

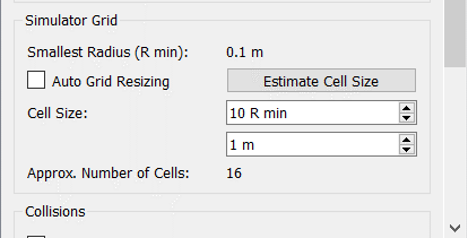

- Define the simulation options

Simulation Set Up in EDEM

Create an EDEM System

Run the Simulation

Post-processing

For components that are interacting in EDEM, the animation can be visualized in EDEM through the Analyst page.

Flexible Body Coupling

An equivalent flexible body H3D file of the wheel is available.

)

)

.

.