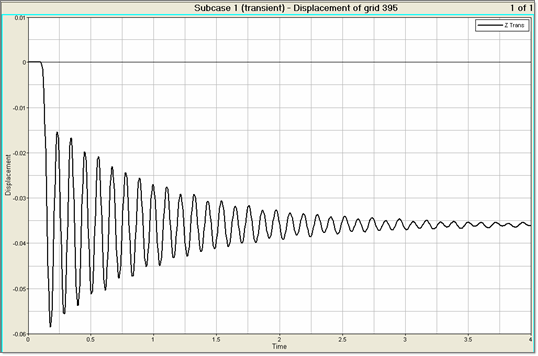

OS-T: 1310 Direct Transient Dynamic Analysis of a Bracket

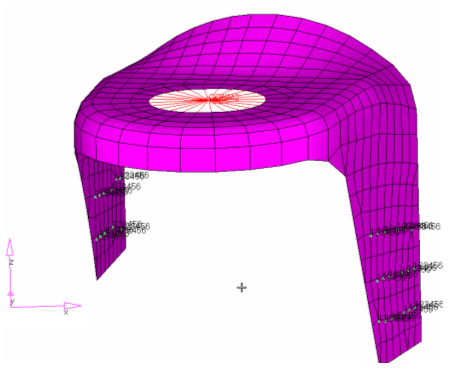

In this tutorial, an existing finite element model of a bracket is used to demonstrate how to perform direct transient dynamic analysis using OptiStruct. HyperGraph is used to post-process the deformation characteristics of the bracket under the transient dynamic loads.

Figure 1. Finite Element Model of the Bracket

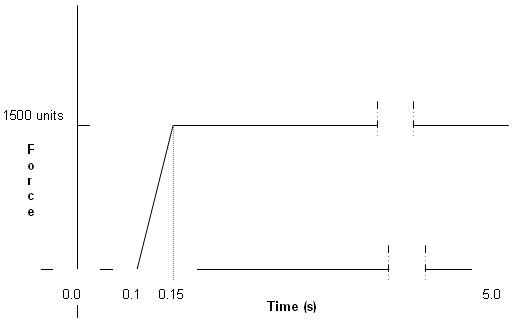

Figure 2. Time History of Applied Loading

Launch HyperMesh and Set the OptiStruct User Profile

Import the Model

Set Up the Model

Create TABLED1 Load Collector

Create TSTEP Load Collector

Create a DAREA Load Collector

Create a TLOAD Load Collector

Create a Load Step

Create Damping Parameters

Create Output Requests

Submit the Job

- bracket_transient_direct.html

- HTML report of the analysis, providing a summary of the problem formulation and the analysis results.

- bracket_transient_direct.out

- OptiStruct output file containing specific information on the file setup, the setup of your optimization problem, estimates for the amount of RAM and disk space required for the run, information for each of the optimization iterations, and compute time information. Review this file for warnings and errors.

- bracket_transient_direct.h3d

- HyperView binary results file.

- bracket_transient_direct.res

- HyperMesh binary results file.

- bracket_transient_direct.stat

- Summary, providing CPU information for each step during analysis process.

.

.

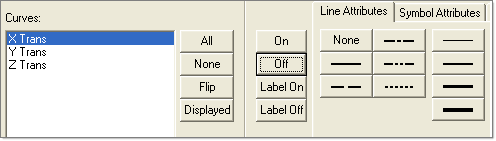

and turn off the curves

and turn off the curves

to fit the y-axis (that is Z displacement) of node 395

in the GUI.

to fit the y-axis (that is Z displacement) of node 395

in the GUI.