Result Types

Results are available for injection, foaming, curing and criterion stages.

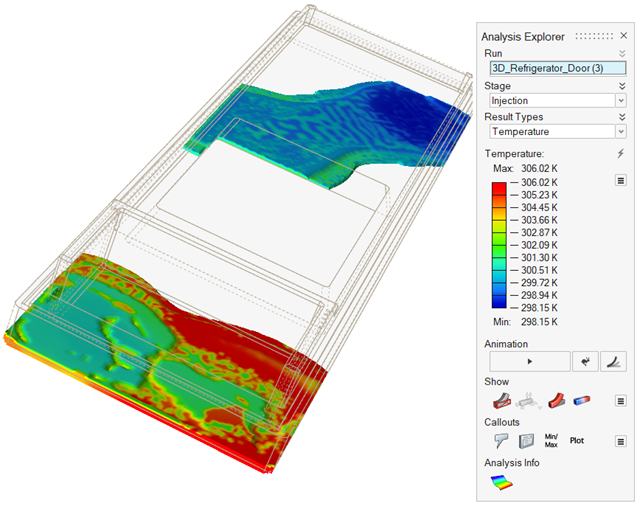

Injection Results

Review material behavior through the injection stage.

| Result Type | Description |

|---|---|

| Temperature | Review the temperature evolution of the material entering the

part cavity. Check regions for excessive heating or cooling.

Determine the appropriate fill speed for uniform temperature

distribution. |

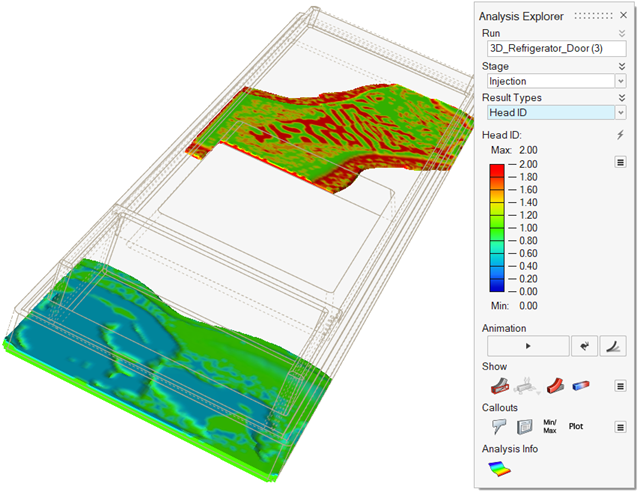

| Head ID | Review injection results for material coming from a

particular nozzle. |

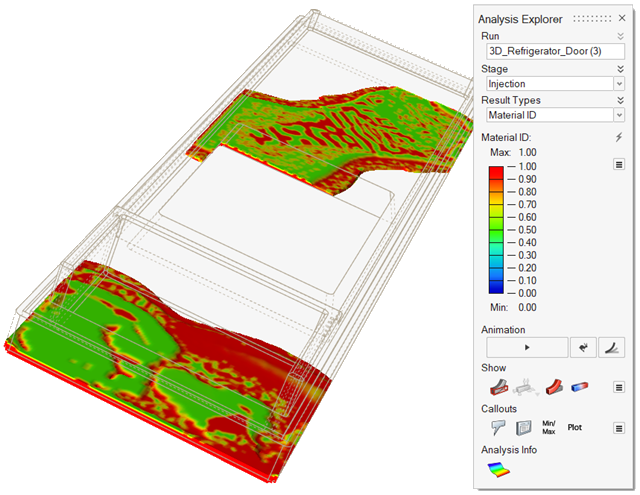

| Material ID | Review results for a particular material. Click the

Show and

Options buttons to change to velocity

contour fill animation. |

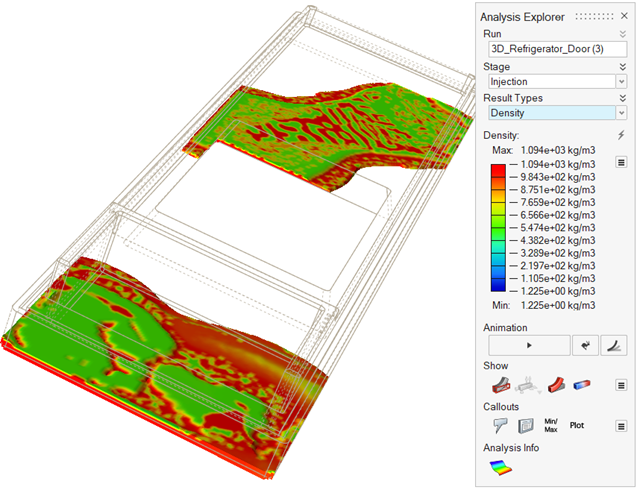

| Density | Consider material density through the progression of the

injection stage. |

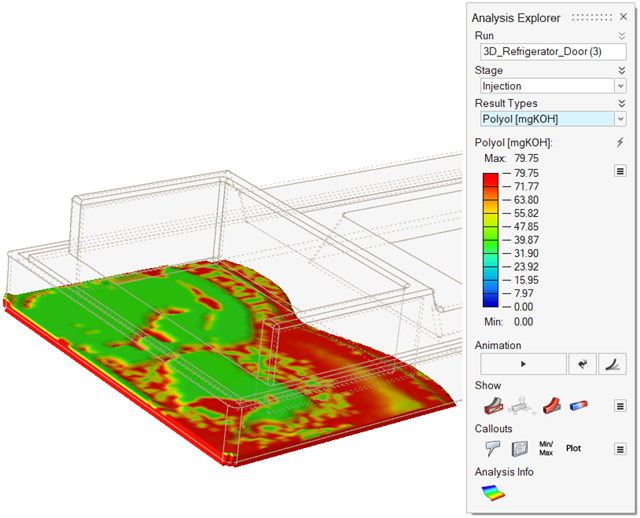

| Polyol (mg KOH) | Review levels of polyol in the material in mg KOH

units. |

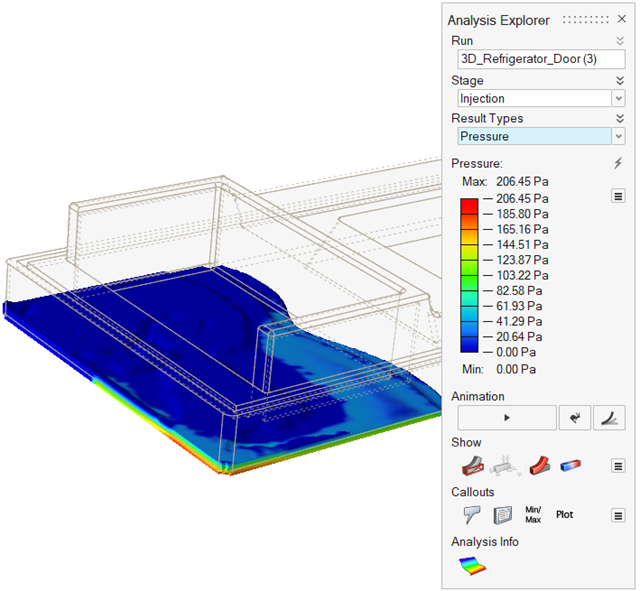

| Pressure | Review the impact of pressure on the material during the

injection stage. |

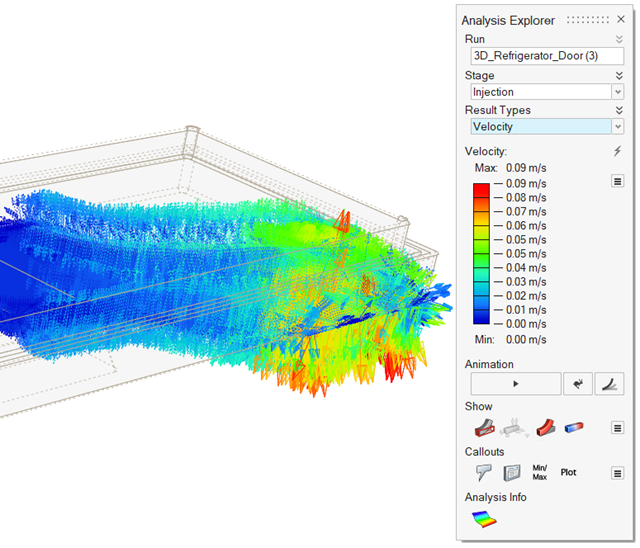

| Velocity | Review the filling process represented with vectors that help

you detect turbulences and velocities in the material. |

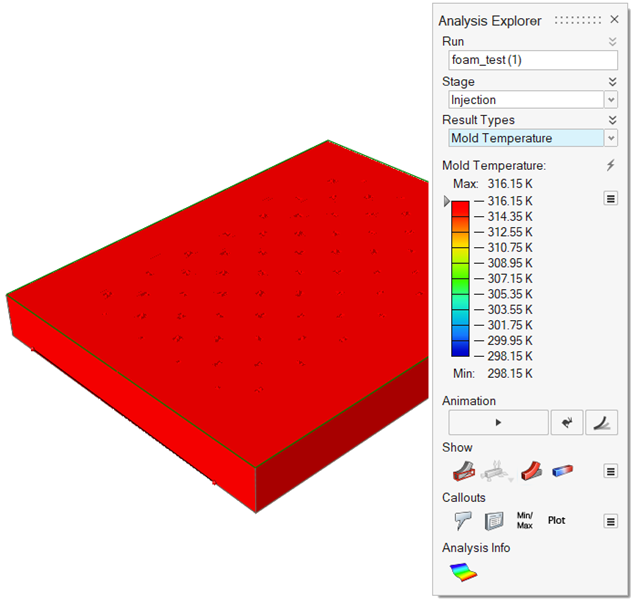

| Mold Temperature | Review the temperature variance in the mold throughout the

injection stage. |

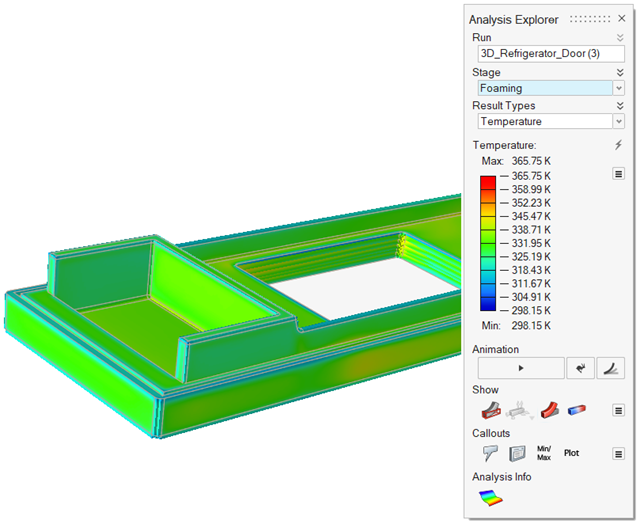

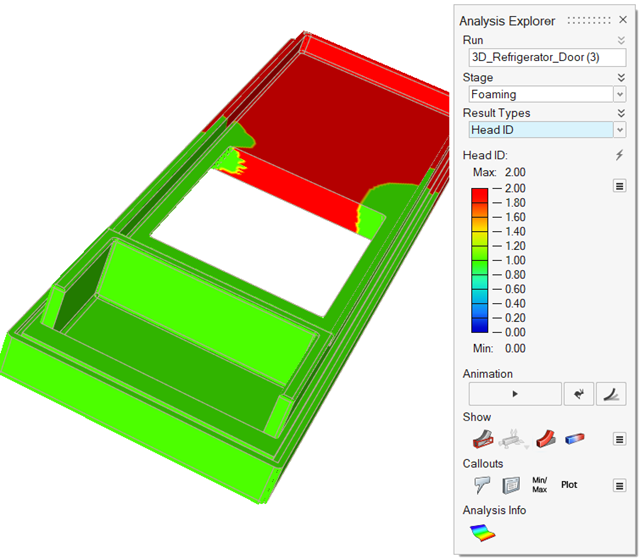

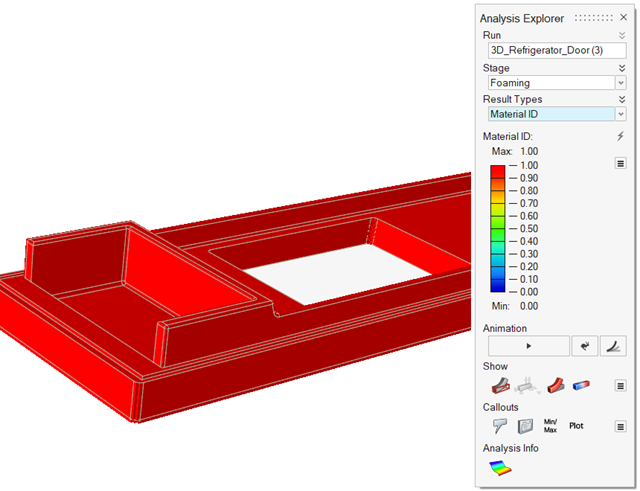

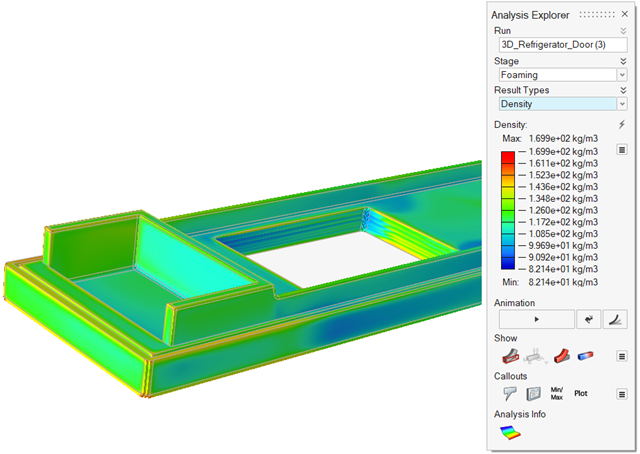

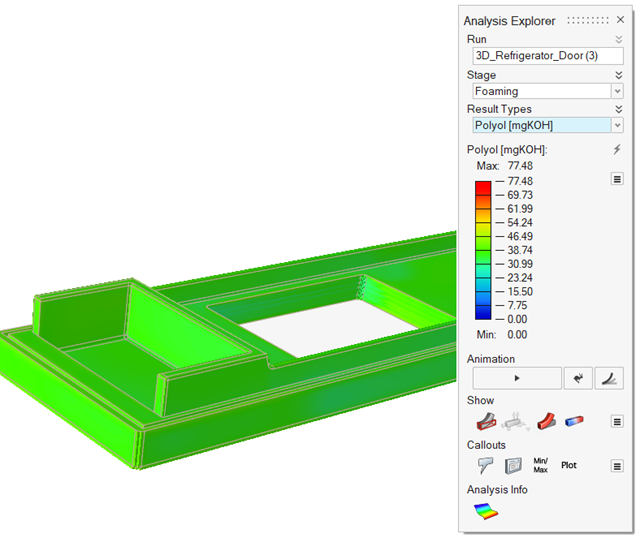

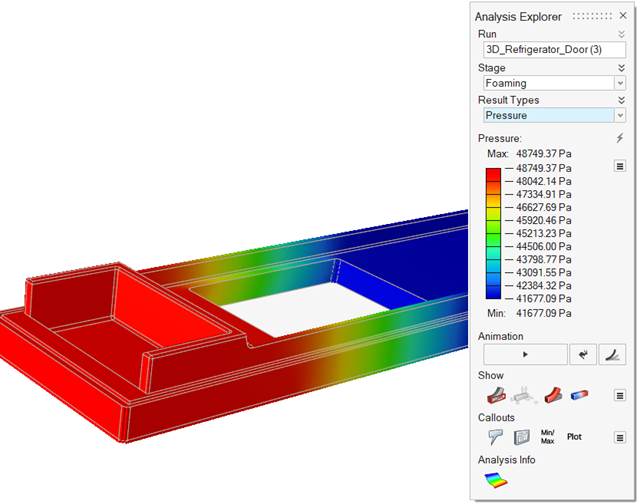

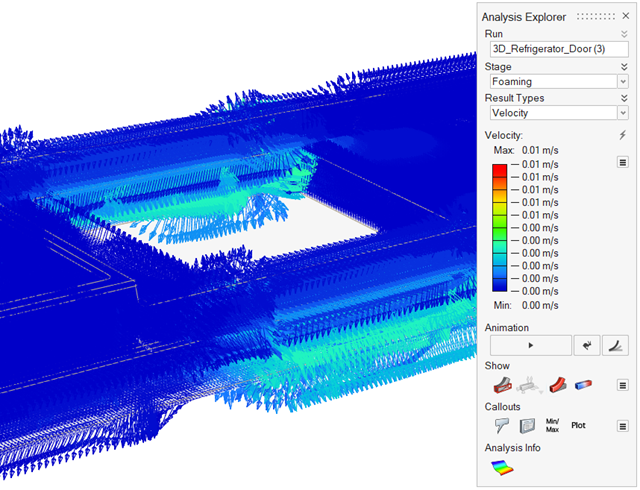

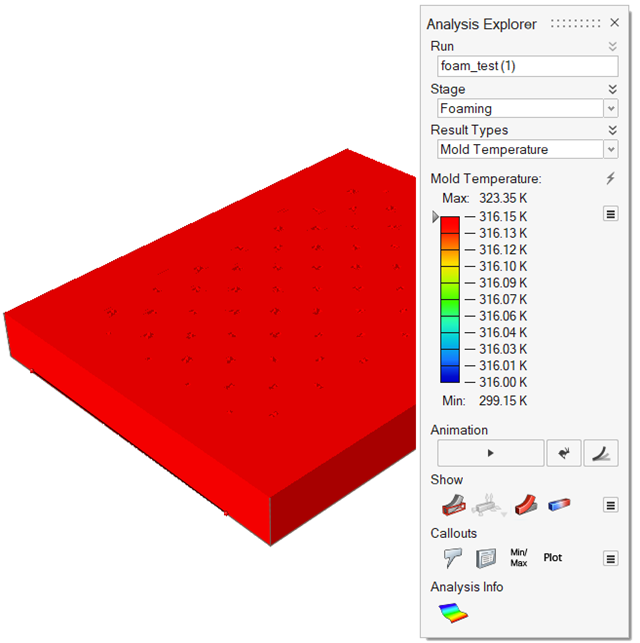

Foaming Results

Review material behavior through the foaming stage.

| Result Type | Description |

|---|---|

| Temperature | Review the temperature evolution of the material during the

foaming stage. |

| Head ID | Review the foaming results for material coming from a

particular nozzle. |

| Material ID | Review results for a particular material. |

| Density | Consider material density through the progression of the

foaming stage. |

| Polyol [mg KOH] | Review levels of polyol in the material in mg KOH

units. |

| Pressure | Review the impact of pressure on the material during the foaming stage.  |

| Velocity | Review the filling process represented with vectors that help you detect turbulences and velocities in the material.  |

| Mold Temperature | Review the temperature variance in the mold throughout the

foaming stage. |

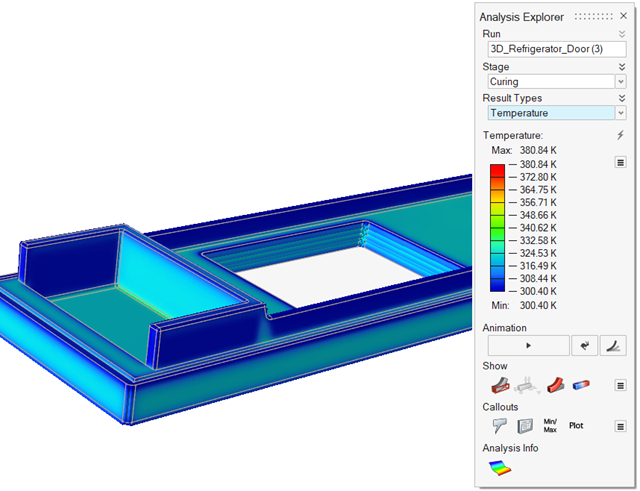

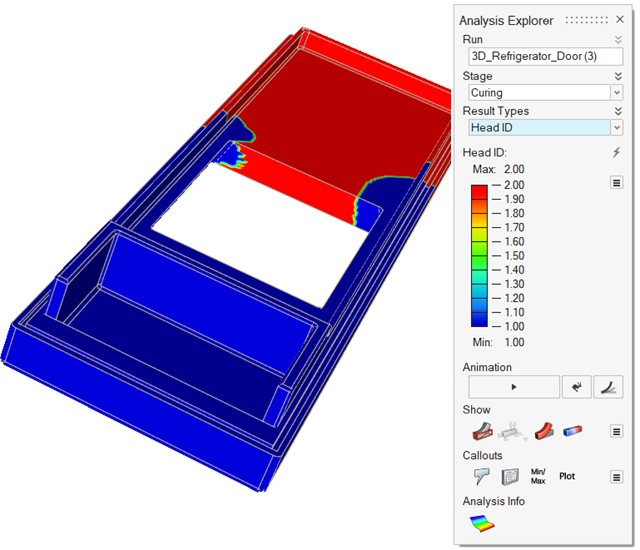

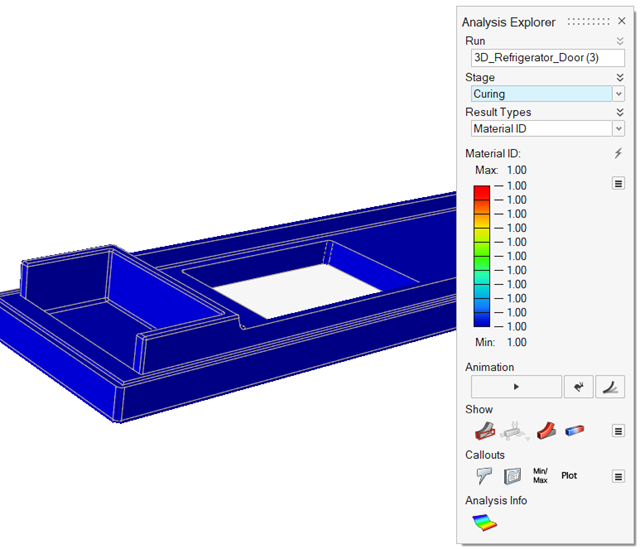

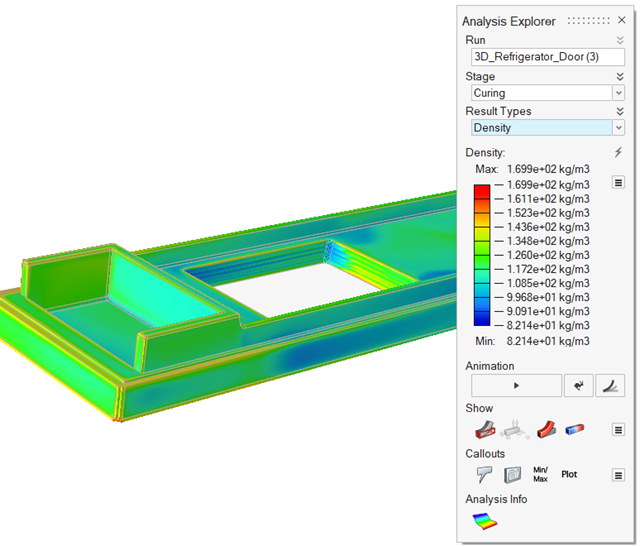

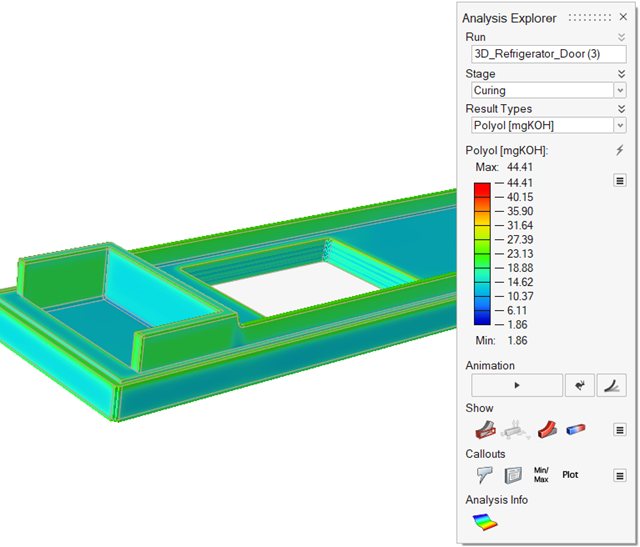

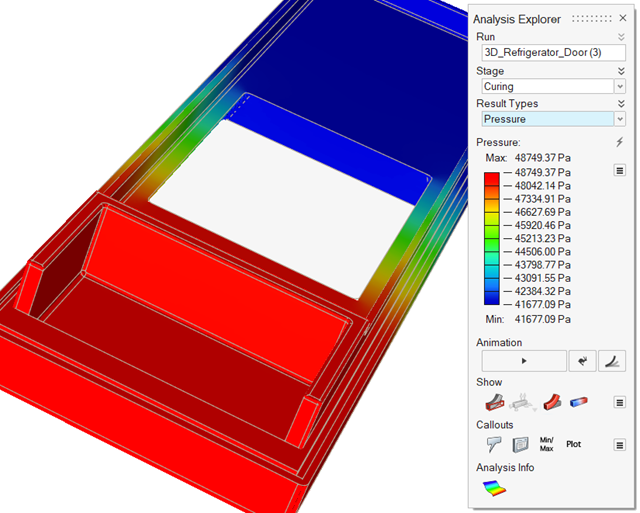

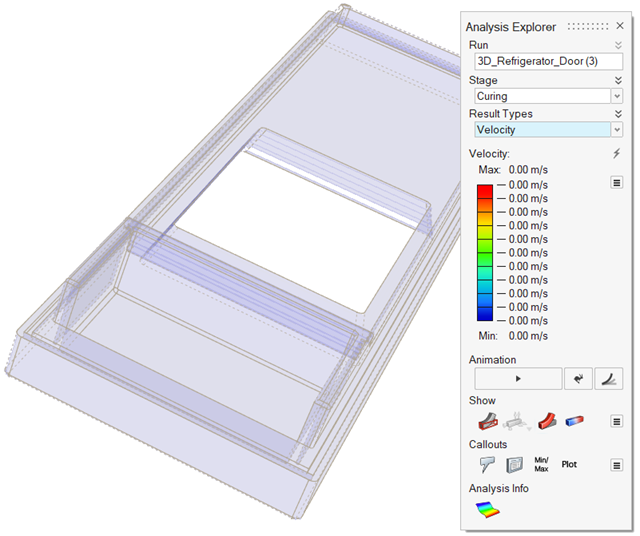

Curing Results

Review material behavior through the curing stage.

| Result Type | Description |

|---|---|

| Temperature | Review the temperature evolution of the material during the

curing stage. Check regions for excessive heating or

cooling. |

| Head ID | Review curing results for material coming from a particular

nozzle. |

| Material ID | Review curing results for a particular material. |

| Density | Consider material density during the curing stage. |

| Polyol [mgKOH] | Review levels of polyol in the material in mgKOH units. |

| Pressure | Review the impact of pressure on the material during the

curing stage. |

| Velocity | Review the curing process represented with vectors that help

you detect turbulences and velocities in the material. |

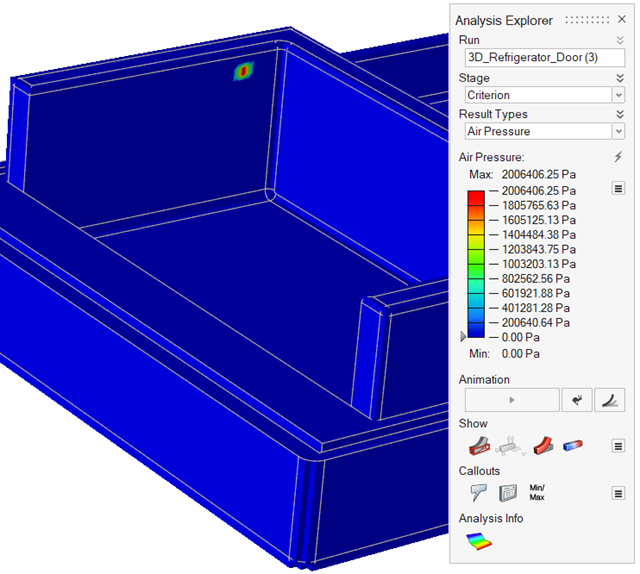

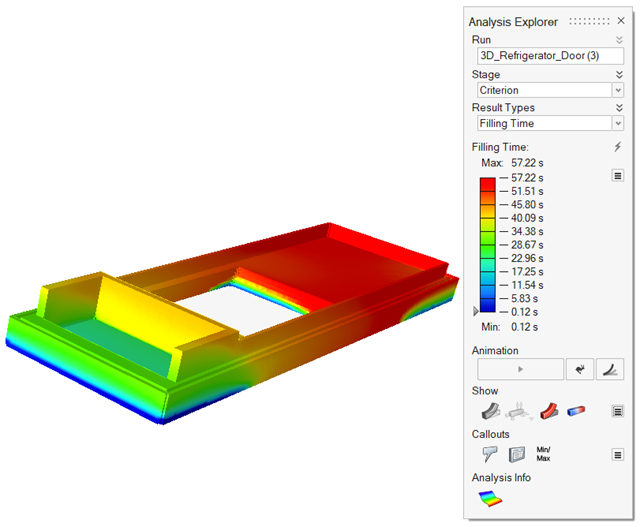

Criterion Results

Review the effects of air pressure and filling time at the end of the foaming process.

| Option | Description |

|---|---|

| Air Pressure | Display the accumulated air pressure effects on the part at

the end of the simulation. Look for porosity and void

defects. |

| Filling Time | Review the time the material takes to reach different areas of the mold. Consider adjustments to nozzle paths and tooling.  |