How do I use Temperature Dependent Stress Strain Data for Tool Deflection Analysis?

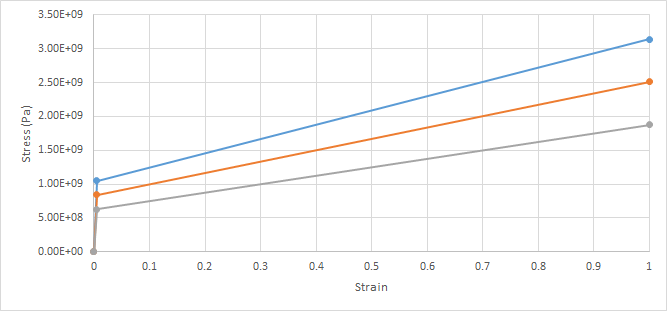

- Inspire Extrude was enhanced to perform temperature-dependent tool deflection analysis. This analysis requires temperature-dependent stress/strain data and will use the built-in data for this purpose.

- There is no GUI to specify the required stress-strain material data, but the user can provide their own data.

- Inspire Extrude exports the data as a text file in the run folder, and if the

user provides a similar text file in the run folder, the interface will

automatically use the user's data instead of its built-in data.

Steps to setup model with default stress strain curve in Inspire Extrude database:

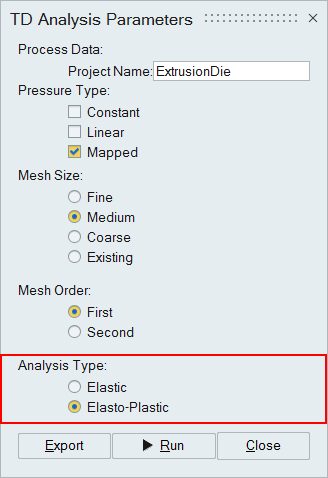

- Setup tool deflection model as per Tutorial #5 on Tool Deflection Analysis.

- When running analysis select "Elasto-Plastic" option.

- Inspire Extrude will run the simulation using default stress strain curve.

- Default tool material data which is used in analysis is saved in working folder with name "tool_mat_data_auto.txt". This file can be modified and used for next simulation.

Steps to setup model with user defined stress-strain curve:

- Keep model ready for simulation. Follow steps below before running simulation.

- Get "tool_mat_data_auto.txt" file as eplained in the previous section.

- Save this file to folder in which you have *.c2em file and rename it to "tool_mat_data_user.txt"

- Modify data in "tool_mat_data_user.txt" as per your tool material

- Go back to Inspire Extrude and run the simulation.

What temperature are the die plates initialized with for this analysis?

All die plates are initialized with a temperature of 477 °C or 890 °F.