Technical Capabilities

Overview of nanoFluidX technical capabilities.

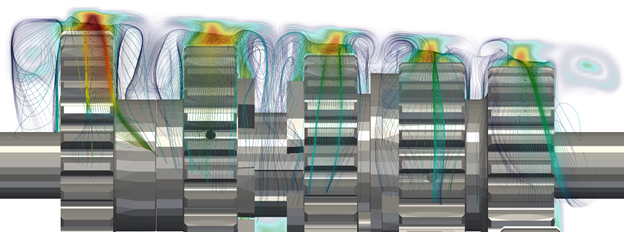

Figure 1. Streamlines Around a Gearbox Layshaft

Formulation

- SPH Weakly-Compressible formulation

- The most wide-spread and most developed approach to the SPH, allows for 1% compressibility of the fluid and gives significant performance and stability improvements over an incompressible formulation.

- Transport Velocity formulation

- Improves the overall behavior and accuracy of the code. Furthermore, including transport velocity has been shown to mimic turbulent-like behavior in the bulk flow, which is indeed a unique capability among the industrial SPH solutions.

Physics

- Free-surface and high-deformation fluid flows

- SPH formulation implemented in nanoFluidX ensures conservation of mass, momentum and other physical properties even for highly convective flows. Perfect advection or properties and maintaining a sharp fluid interface gives a key advantage to nanoFluidX over the more conventional Finite-Volume codes when it comes to high-deformation flows.

- Multiphase flows

- nanoFluidX can reliably handle large density ratio (over 1000:1) multiphase flows. Windage effects can be dramatic in the chaotic flows nanoFluidX is designed for and a strong multiphase capability is critical to ensuring accurate results.

- Surface tension models

- nanoFluidX uses a state-of-the-art surface tension model developed at Technical University of Munich to handle multiphase surface tension.

- Aeration-viscosity models

- Aeration-viscosity models account for the fact that air entrapment in oil changes the effective viscosity of the oil. The feature can significantly improve torque estimates, especially when the majority of the torque is coming from the shear stresses.

- Heat Transfer

- A fully coupled transient thermal solver for conjugate heat transfer, with the option of specifying temperature dependent viscosity for fluids.

Boundary Conditions & Motion

- Slip/no slip wall boundary conditions

- Standard friction and frictionless wall boundary conditions.

- Inlet/outlet boundary conditions

- SPH inlet/outlet boundary conditions are complex to implement, but nanoFluidX contains several options for velocity and ambient inlets and outlets. Periodic boundary conditions are also available.

- Prescribed regions

- Arbitrary regions can be defined with imposed velocities, body forces or temperatures. These allow simulations of components like pumps and heat exchangers.

- Defined body motion

- Pre-defined simple (rotation, translation) or complex (planetary, conrod) motion definitions. Also capability to define an arbitrary 6DOF motion, for example chain motion.

- Rigid body motion

- Fluid-solid motion coupling enabling simulation of buoyant and fluid driven objects, e.g. ships, platforms and hydro-turbines.

- Variable body force

- Allowing for extremely efficient tank sloshing simulations or simulations of gear-train components under cornering forces.

Other

- Restart capability

- Simulations can be restarted with modified boundary conditions, provided the model topology has not changed. This makes parametric sweeps and studies much more efficient, e.g. simulating multiple rotation speeds. Restarts can also take place on different hardware to the original simulation, for example restarting from 4 to 6 GPU’s to accelerate it.

- Known limitations

-

- There are major time-scale differences between fluid and thermal dynamics, so heat transfer simulations are currently very expensive to perform. Coupling between nanoFluidX and AcuSolve is now possible.

- Surface tension coefficient for single phase flows requires tuning, as no universal single phase surface tension model exists.

- Large negative pressures cannot be accurately handled by the current weakly compressible formulation unless there is an accurate preservation of the particle-filled volume in the domain.

- Lack of pressure boundary conditions.

- No compressibility or phase transitions.

Hardware

We officially recommend NVIDIA Tesla V100, P100 and K80 accelerators, as they are well-established GPU cards for scientific computing in data centers and nanoFluidX has thoroughly been tested on them. Nvidia Tesla M series (M40, M60) is also suitable for running nanoFluidX, however these cards only have meaningful single precision performance – running double precision is essentially impossible.

A number of other NVIDIA GPU cards (Quadro series, GeForce series, etc.) have a Compute Capability that in principle is suitable for nanoFluidX. However, Altair does not guarantee accuracy, stability and overall performance of nanoFluidX on these cards. Be aware that the current NVIDIA EULA prohibits using non-Tesla series cards as a computational resource in bundles of 4 GPU’s or more.

- Minimum hardware requirements

- 64GB RAM

- Supported platforms

-

- Several common Linux distributions with GCC newer than 4.8.5 and GLIBC 2.17 (RHEL 7.x and compatible Scientific Linux, CentOS, Ubuntu 14.04, 16.04 and 18.04, OpenSUSE 13.2 etc.). For a full list please contact your distributor.

- NVIDIA CUDA 8.0 and OpenMPI 2.1.6 – shipped with the binary.