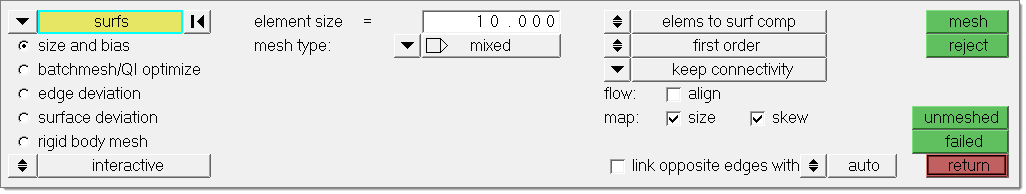

Automesh Panel |

|

|

|

|

|

Automesh Panel |

|

|

|

|

The options in the panel can be set in any order that you feel comfortable using. Moving from subpanel to subpanel will not cause you to lose work. When finished making all your selections, start the meshing process using the mesh button on the right side of the panel.

| • | Set the panel mode by selecting the appropriate subpanel |

| • | Select the meshing method by setting the entity selector to surfs or elems |

| • | Make the required element criteria settings |

| • | Set any algorithm options |

| • | Select the area to be meshed using the entity selector and any extended selection methods desired. |

| Note: | The unmeshed and failed selection buttons on the right side of the panel can be used to make pre-defined surface selections if desired. |

The Automesh panel contains the following subpanels:

Size and bias meshing is a very flexible and powerful meshing method. A minimum of inputs are required for the element criteria settings. The algorithm options can set preferences on how to handle certain situations when encountered in the geometry. When using existing finite elements as the basis for mesh generation, feature recognition settings allow the mesher to break up the areas defined by the selected elements into logical groupings with mesh controls set for each group boundary. This meshing mode works interactively or automatically. In interactive mode, a great deal of manual control is presented via the Secondary Automesh panel during the mesh generation stage. Interactive meshing allows you to control mesh size and element type, and to set different mesh generation algorithms and test element quality on a surface-by-surface basis. The resulting modified mesh can be updated at any time, giving immediate feedback as to the effectiveness of the change. When meshing in the automatic mode, the mesh will be generated using only the settings, criteria and options set in the Automesh panel. Size and biasing produces a mesh with consistent element size. If meshed interactively, the number of elements (element density) node spacing (biasing), element type and mesh style can be modified for each surface face and edge. Panel Inputs

|

Quality Index meshing is an iterative automatic mesh generation method driven by element quality criteria. During the mesh generation process, the quality index of the mesh is determined by evaluating each element against a set of element quality tests. If all required element quality criteria are passed, then that element has a perfect quality index of zero. As the element quality deteriorates, the quality index value increases; so a lower quality index score indicates an element more closely meets the ideal quality requirements. The compound quality index sum of the quality index values for each of the elements included in the current meshing area. The quality index value itself has no direct physical meaning; it is a way to compare one generated mesh pattern against another pattern generated for that same area. The quality index based mesh optimization routine attempts to modify the mesh pattern and apply node smoothing routines to obtain a lower overall quality index value. For more information on element quality index, refer to Quality Index calculations.

Panel Inputs

|

Use the Edge Deviation subpanel to set specific meshing parameters to limit how far the mesh elements can deviate from the actual edges of the surfaces meshed, or when in the case of re-meshing elements, deviation from inferred edges based on features. Controls for the minimum and maximum allowable element size, edge deviation and maximum angle are introduced with this method. Edge deviation normally occurs on curved edges, because individual elements have straight edges and therefore can only approximate a curve.

Edge deviation applies to both surface geometry and when re-meshing elements. Automeshing on the edge deviation subpanel automatically selects the best element size to approximate a curve, within the limits that you specify. The max deviation and max angle settings are the primary controls for this effect.

This method can produce a mesh in which the element size varies, even within the same surface. Areas of high curvature will tend to have smaller elements than areas of low or no curvature. The element size boundaries controls this effect.

Panel Inputs

|

This subpanel is only accessible when meshing surfaces. Use the Surface Deviation subpanel to mesh within limits of element deviation from a surface. Similarly to the edge deviation subpanel, meshing behavior on this subpanel is driven by distances between flat elements and model geometry. When flat elements are used to approximate a curved surface, there is always a discrepancy between each element and the actual curve of the surface, because the element uses a straight line between two nodes:

A gap is visible between the curved edge of the surface and the element edges. The surface deviation automesh method chooses the mesh density based on the severity of this deviation. Where the threshold deviation would be exceeded, smaller elements are used to reduce the deviation:

The surface deviation meshing works only in an automatic mode; interactive meshing with the secondary automesh panel is not possible. However, use the refine function to set a specific desired mesh size for a point, line or surface face. This option accesses another temporary subpanel that is slaved to the surface deviation subpanel. From this subpanel, select fixed points, lines, or surfaces to define an area in which you desire a more refined mesh. You can specify a different element size for these areas, which displays as a color-coded numeric value: yellow for points, green for lines, or red for surfaces. An option to show all or show active toggles the view of these numeric values; show active displays only the refinement value for the most recently selected point, line or surface, while show all shows all values for all selected entities. After specifying refinement options, click mesh to create a smoothly-scaled mesh from your base element size to the size specified in the refine options.

Panel Inputs

|

Use the Rigid Body Mesh subpanel to create a quick mesh to represent the topology of a rigid object. Only the automatic meshing mode is available. Rigid bodies are surfaces that are expected to be treated as undeformable in the solution. One example of a rigid body is in metal-forming. When modeling the results of a die pressing down on a metal sheet, it’s important to model the shape of the die because that determines the shape of the metal sheet after being pressed. However, during a forming analysis the stresses and deformations of the die itself are not of interest, only those of the formed metal sheet. Other applications for rigid bodies include the impactors used in vehicle crash simulation. A mesh that accurately represents the rigid geometry is important for such simulations to allow the solver collision detection routines to work effectively and accurately. Since stress and deformation of the rigid body are not calculated by the solver, the rigid body mesh focuses on accurately modeling the shape of the body rather than on producing a high-quality mesh. To this end, it uses the same faceting and shading routines that are used for drawing the model graphics. The resulting mesh may have high aspect ratio or extremely tapered elements that would not be suitable for solution, but can accurately represent the geometry. The images below illustrate the differences between surface deviation meshing and rigid body meshing. Both meshes were generated using the same parameters in terms of min/max element size, maximum deviation and feature angle, and mesh type.

Panel Inputs

|