bounding surfaces subpanel (Solids panel) |

|

|

|

|

|

bounding surfaces subpanel (Solids panel) |

|

|

|

|

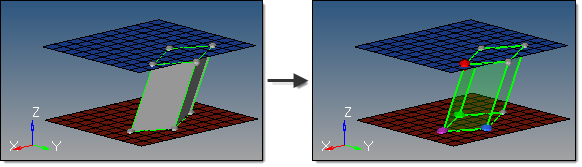

This subpanel creates solids by converting closed surface shells which define the solid boundary.

Six inputs are required to create a solid using this method:

| • | The surfaces that define the continuous, closed shell. The surface selection must be completely closed; if the surface selection contains any free edges or gaps, a solid cannot be created. For example, a collection of surfaces representing an open cardboard box (like an empty cube, but with only five faces) will not work unless the sixth surface face is added. Similarly, a selection of surfaces that has a tiny gap where two corners do not exactly meet also will not work. When attempting to create solids in cases such as this, a red indicator will highlight problem areas. Geometry cleanup tools, such as the Edge Edit or Quick Edit panels, can then be used to correct the issues. |

No solid faces may be selected as input--only true 2D surfaces.

The auto select solid surfaces option allows for a single surface to be selected in the graphics area and the other surfaces that form a continuous shell are then automatically selected. This is also useful to detect selections that may have errors, as a continuous shell will not be selected.

| • | The create in method, which defines the resulting solid body component organization. |

Specifying current component organizes the new solids and the selected surfaces to the current component.

Specifying surfs component adds the new solids to the same component that the selected surfaces already belong to. If the input surfaces are in different components, the result is not predictable.