Calculate and Assign Midmesh Thicknesses

Calculate and assign the thickness of a midmesh from solid geometry using the Midmesh Thickness tool.

The thickness will be assigned to the midmesh either on node card, element card,

nodal thickness on element card, or as properties on elements or components

depending on the solver profile you are using.

Restriction: Only

available in the OptiStruct, Radioss, Abaqus, LS-DYNA, PAM-CRASH 2G, or

Nastran solver profiles.

From the menu bar, click .

Select Midmesh and Solid Inputs

The midmesh and solid can be specified by manually selecting entities from the current HyperMesh session, or by selecting external geometry or FE solver decks as input.

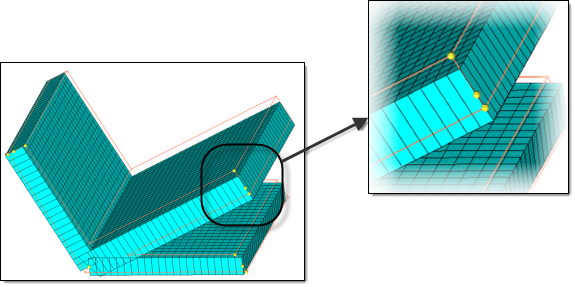

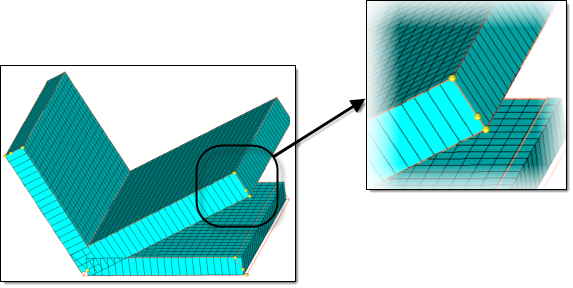

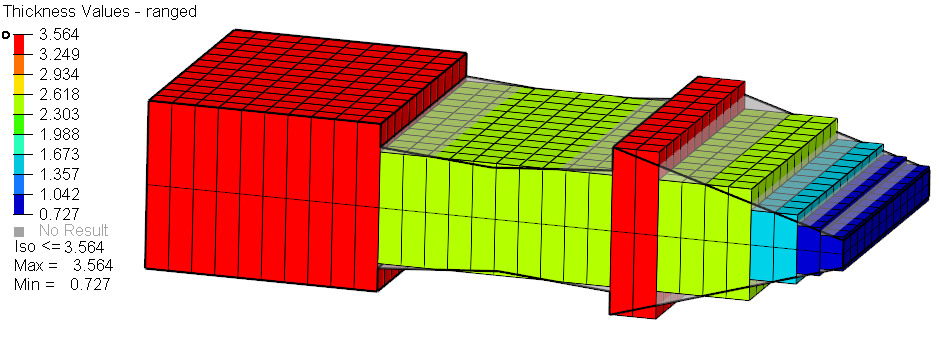

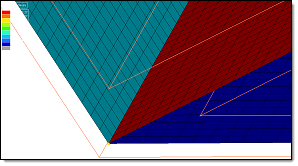

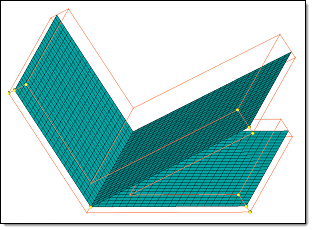

Figure 1. FE and Geometry with Traditional Element Visualization

Select midmesh and solid inputs.

| To select input from | Do this |

|---|---|

| External geometry/FE solver decks |

|

| Existing entities |

|

Define Thickness Output

Calculate and assign a thickness on the midmesh.

Define Visualization Settings

Define visualization settings for the midmesh.

Define visualization settings for the midmesh.

| Option | Action |

|---|---|

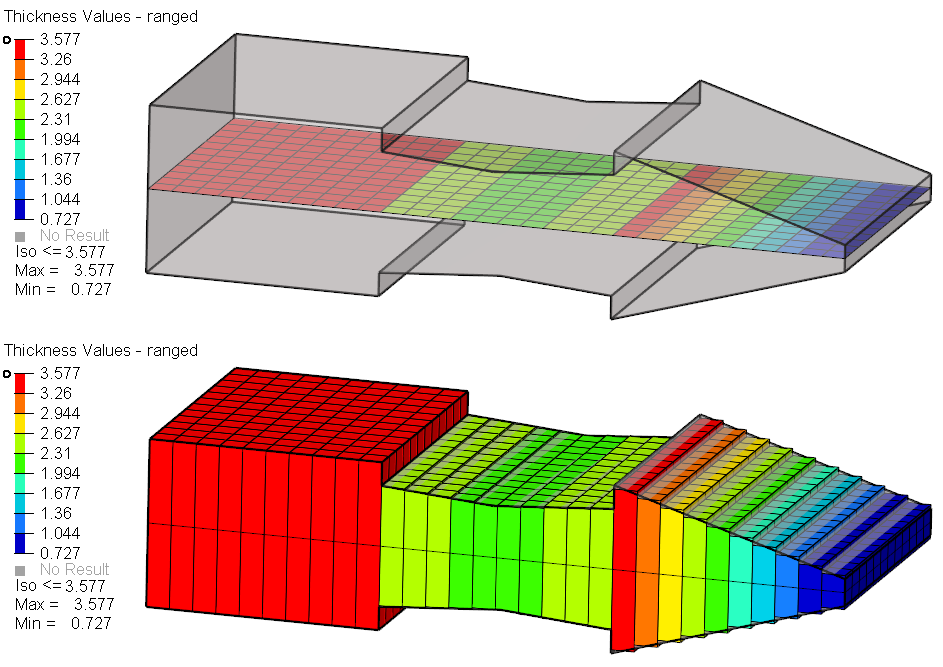

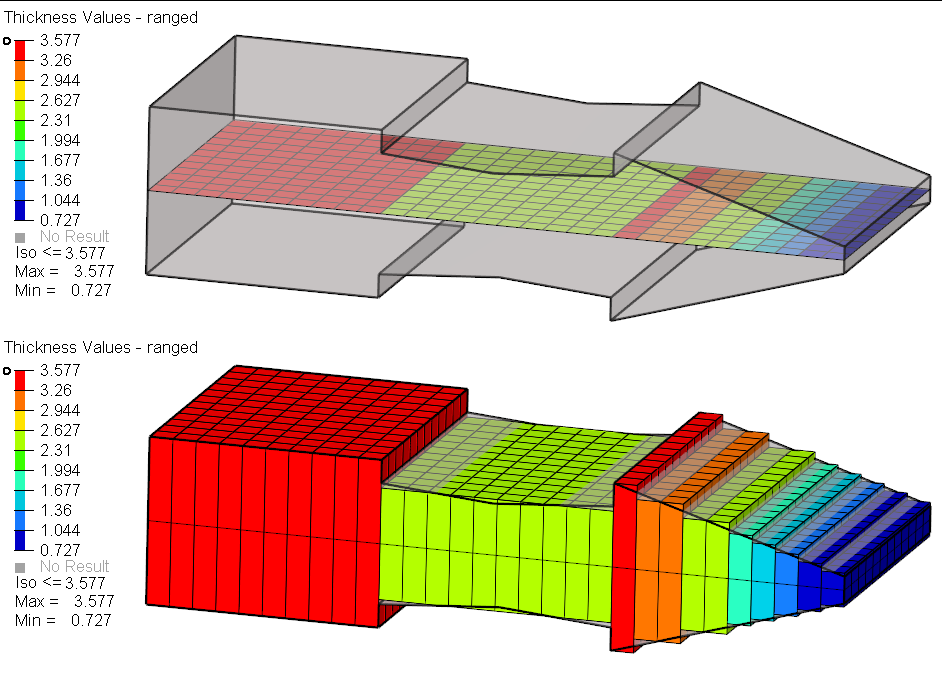

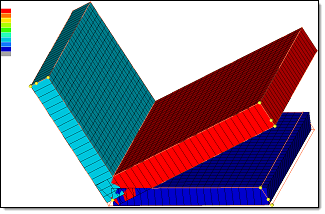

| Element coloring by thickness | Set the Element Color mode to By

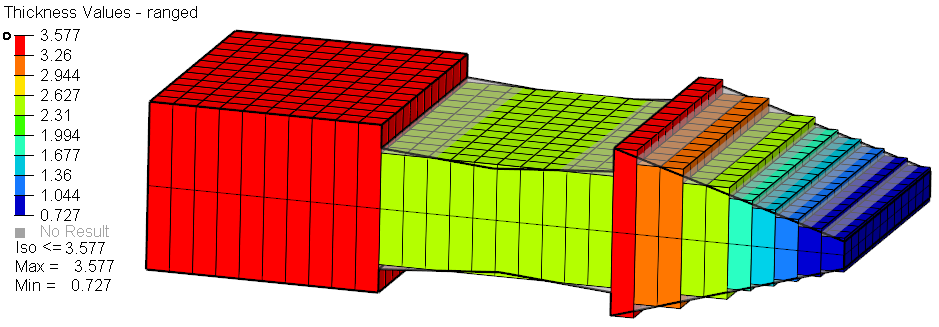

Thickness resulting in a contour plot of thickness. Figure 14. Thickness Contour Applied, 2D Detailed Element Representation |

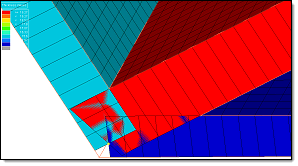

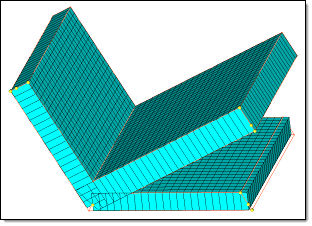

| 2D detailed element representation | Display midmesh elements as 2D with the assigned thickness as

depth. Figure 15. 2D Detailed Element Representation The behavior of 2D Detailed Element

Representation depends on what you assigned a thickness to. For

example, if you assign a component an element thickness, then the

element thickness representation will be displayed. If you assign a

nodal thickness to an element node, then each individual node

thickness will be plotted and you will be able to see the first and

second order trias and quad elements. When you assign a nodal

thickness, you can select the By Thickness

option in the Visualization toolbar to display each node value. If

you assign a nodal thickness, and offset is on, then the element

thickness from the nodes will be calculated, the element will be

offset, and the nodal thickness 2D Detailed Element representation

on the offset elements will be plotted.

Restriction: Composites with variable thickness are not added for this

feature.

|

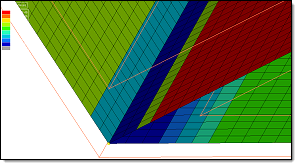

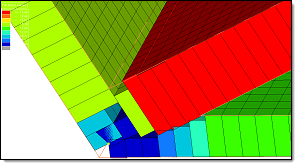

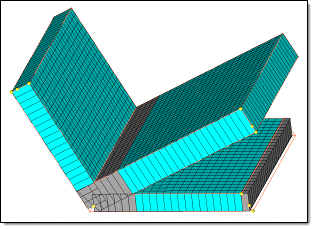

| Highlight corrected elements | Highlight the elements whereby the thickness could not be calculated

from solid, and deploy the correction method. Figure 16. 2D Detailed Element Representation, Corrected Elements Highlighted |