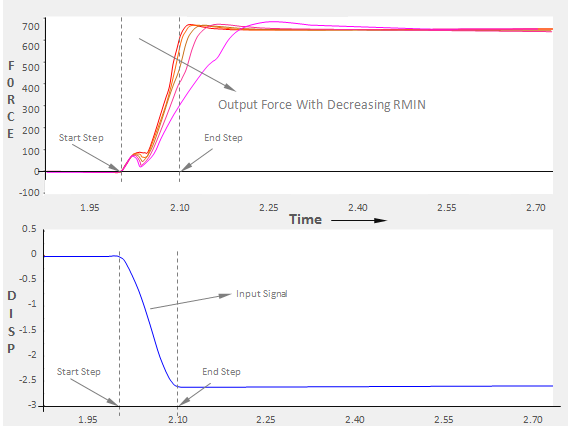

Factor RMIN

During simulation, an additional parameter RMIN is provided for you. If the fitted value of R is greater that RMIN, then the fitted value is used, otherwise RMIN is used. During run time, R affects how quickly the bushing responds to changes in the input.

Figure 1.

A large value of R implies that most of the signal is classified as steady state, so the static effects, which react instantaneously to input changes, will dominate. In contrast, when R is small, most of the signal is classified as transient. Therefore bushing internal dynamics will dominate the response and the response will be somewhat slower.