What is the Bearing in a Metal Extrusion Die?

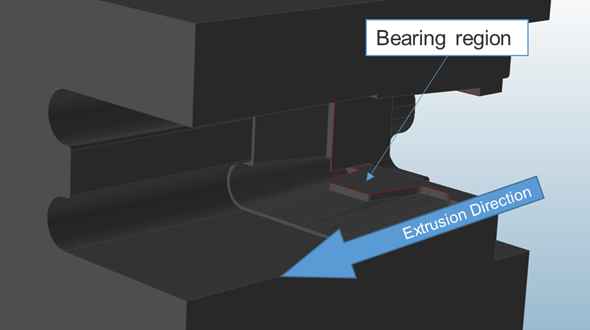

The bearing is the last point of contact in the extrusion die where the workpiece takes the final desired shape. The bearing region is a critical part of the extrusion die, as it controls the metal flow through the die.

Typical problem with incorrect bearing in die

- Large profile deflection

- Imbalanced flow

- Surface cracks

- Variation in grain structure (peripheral coarse grain)

- Die drag due to adhesion of aluminum on the die bearing

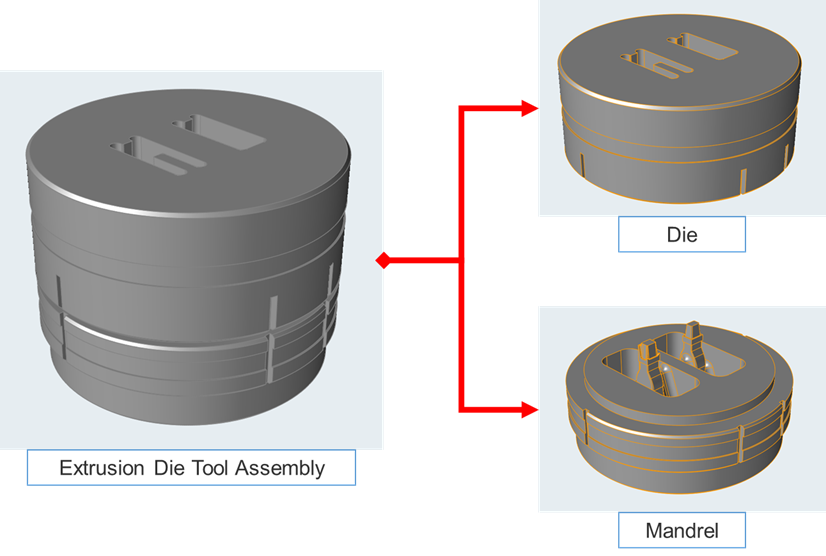

Typical Die Assembly containing - Die and Mandrel:

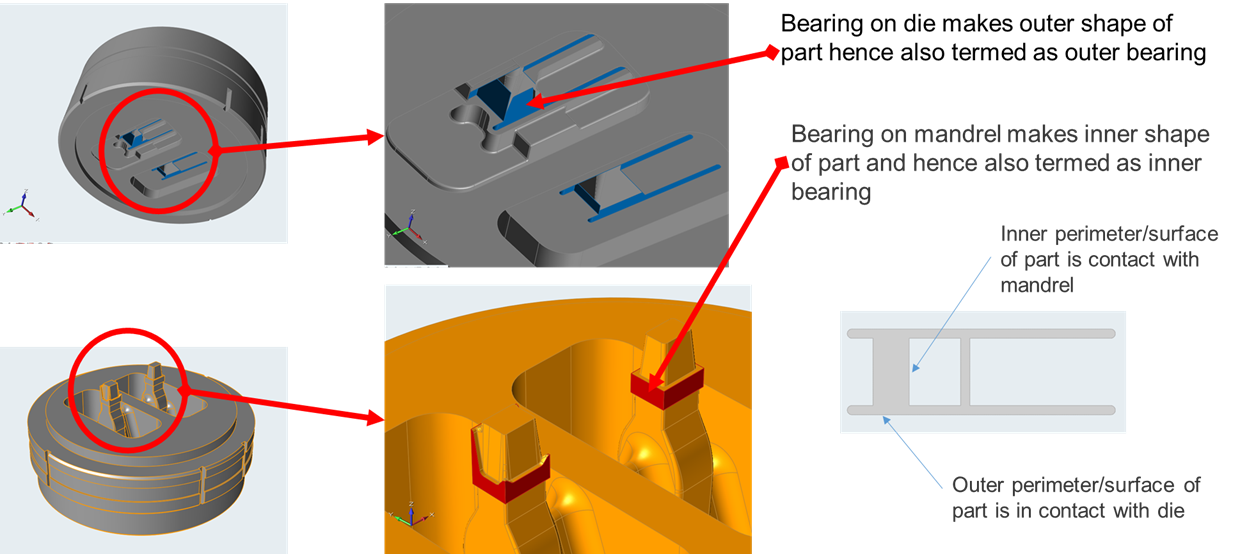

Bearing on Die and Mandrel:

- The bearing on the die makes the outer shape of the part, hence they are also called outer bearings.

- The bearing on the mandrel makes the inner shape of the part, hence they are

also called inner bearings.