ACU-T: 4300 Species Transport Modeling

This tutorial provides instructions for modeling species transport using HyperWorks CFD. Prior to starting this tutorial, you should have already run through the introductory HyperWorks tutorial, ACU-T: 1000 HyperWorks UI Introduction, and have a basic understanding of HyperWorks CFD and AcuSolve. To run this simulation, you will need access to a licensed version of HyperWorks CFD and AcuSolve.

Prior to running through this tutorial, copy HyperWorksCFD_tutorial_inputs.zip from <Altair_installation_directory>\hwcfdsolvers\acusolve\win64\model_files\tutorials\AcuSolve to a local directory. Extract ACU-T4300_HoneyTeaSpecies.hm from HyperWorksCFD_tutorial_inputs.zip.

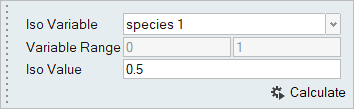

Problem Description

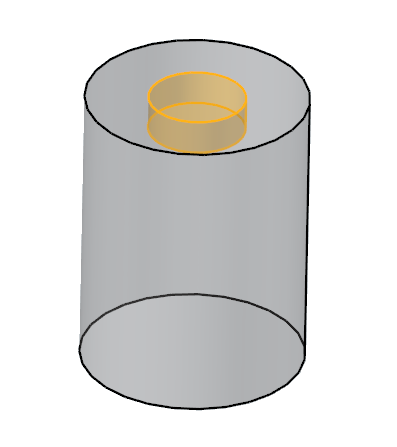

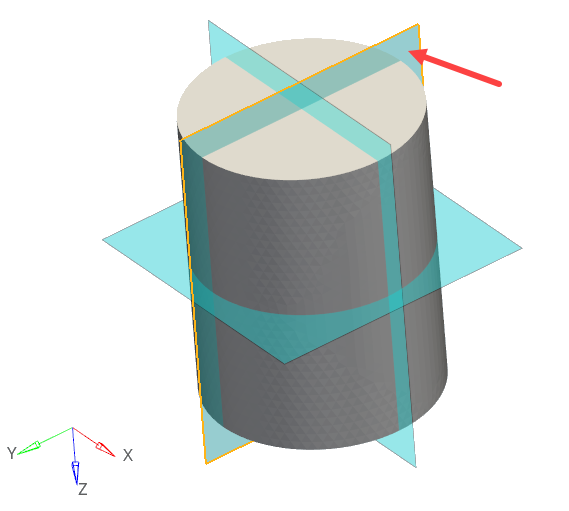

Figure 1.

Start HyperWorks CFD and Open the HyperMesh Database

Validate the Geometry

Set Up Flow

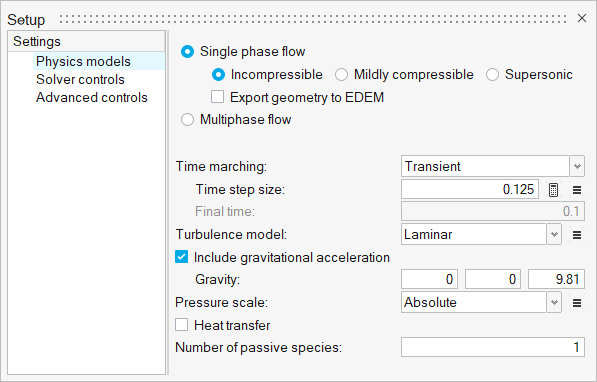

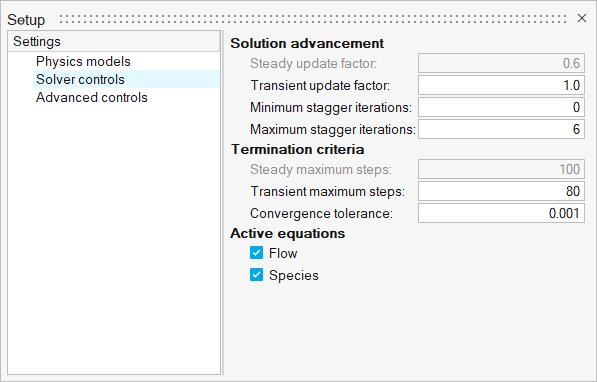

Set the General Simulation Parameters

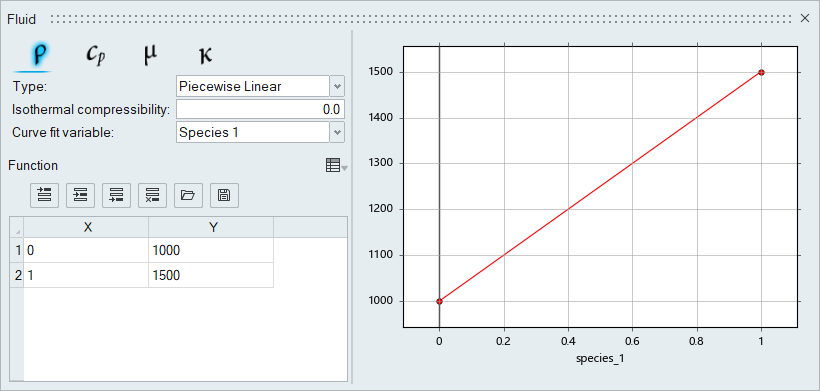

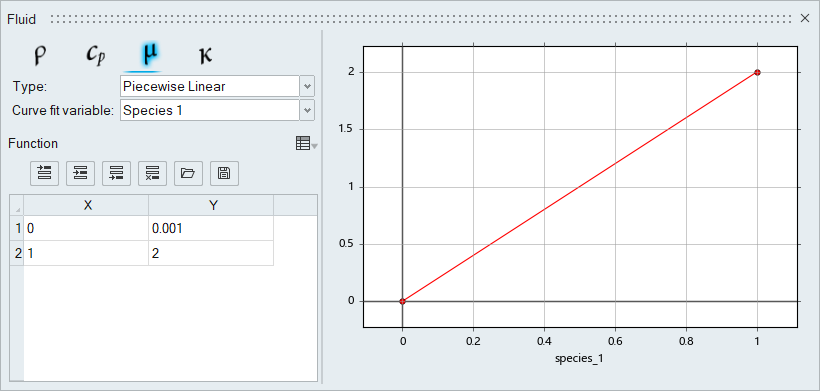

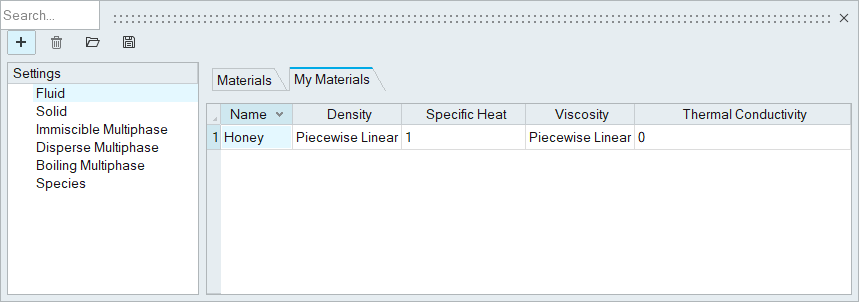

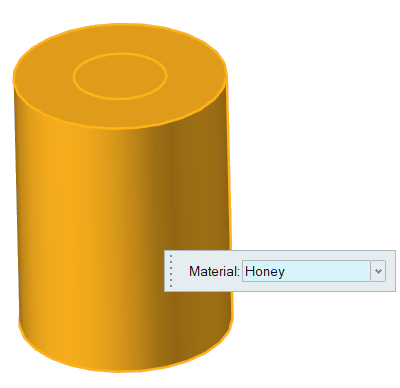

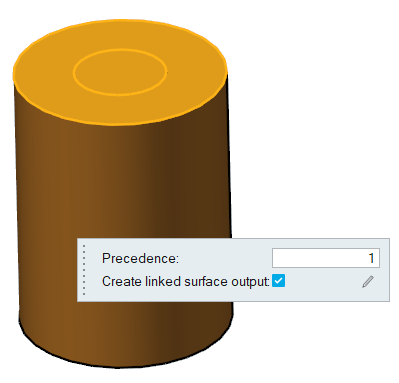

Assign Material Properties

Define Flow Boundary Conditions

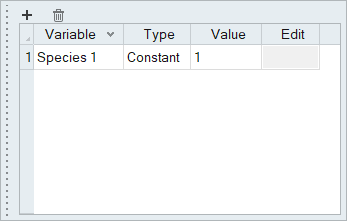

Define Nodal Initial Conditions

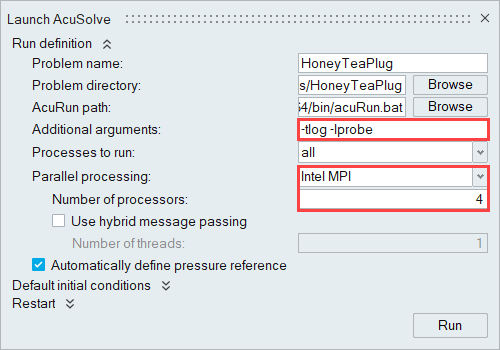

Run AcuSolve

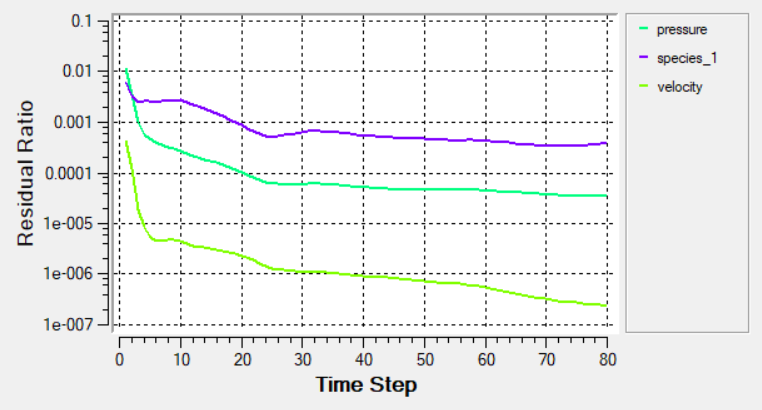

Post-Process with AcuProbe

As the solution progresses, the AcuTail and AcuProbe windows are launched automatically. The surface output and residual ratios can be monitored using AcuProbe.

Figure 21.

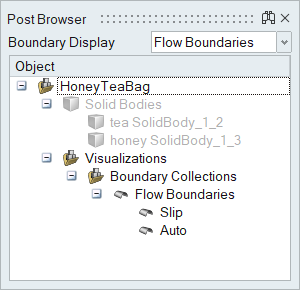

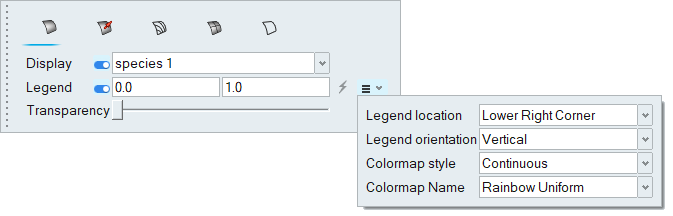

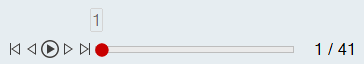

Post-Process the Results with HW-CFD Post

Summary

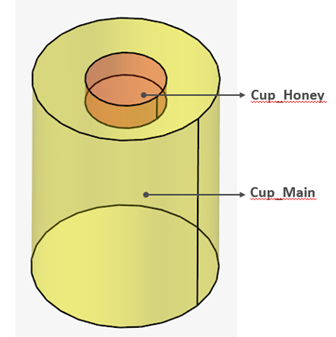

In this tutorial, you successfully learned how to set up and solve a simulation involving species transport using HyperWorks CFD. You started by opening the HyperMesh input file with the geometry and then defined the simulation parameters, fluid material, and boundary conditions. Once the solution was computed, you visualized the results of species transport with help of planes and an iso-surface.