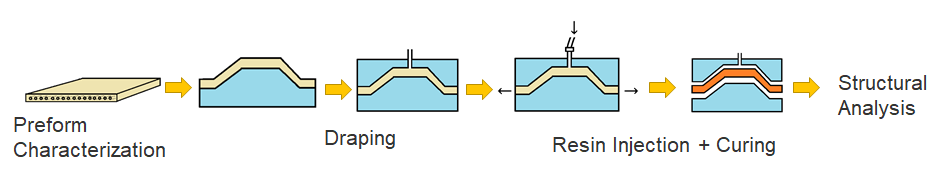

Preform Material Data

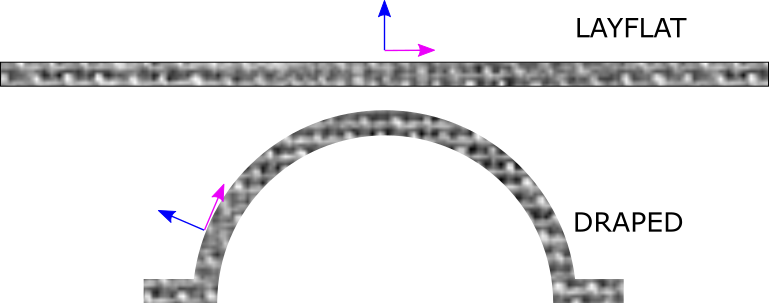

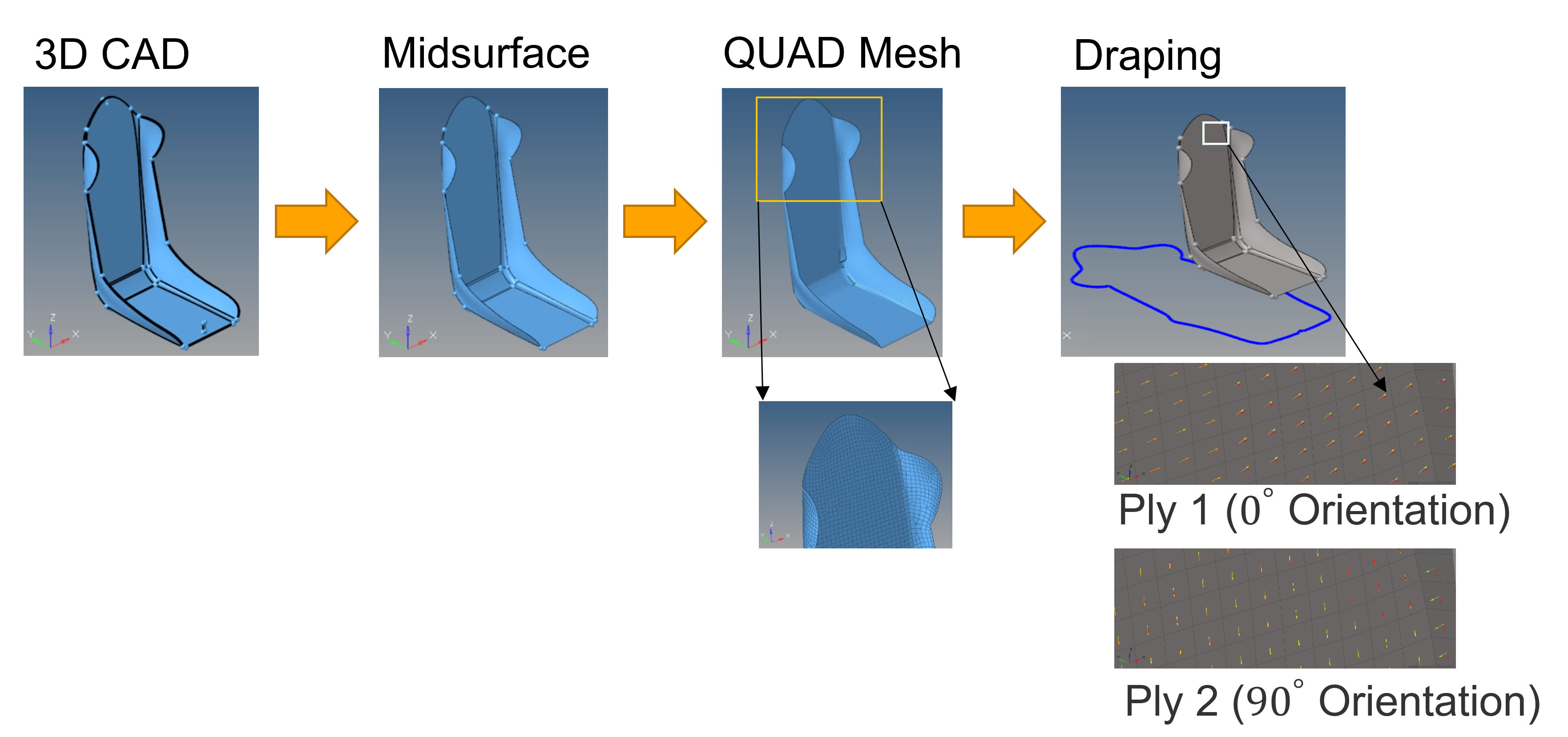

Lay Flat and Draped Preform

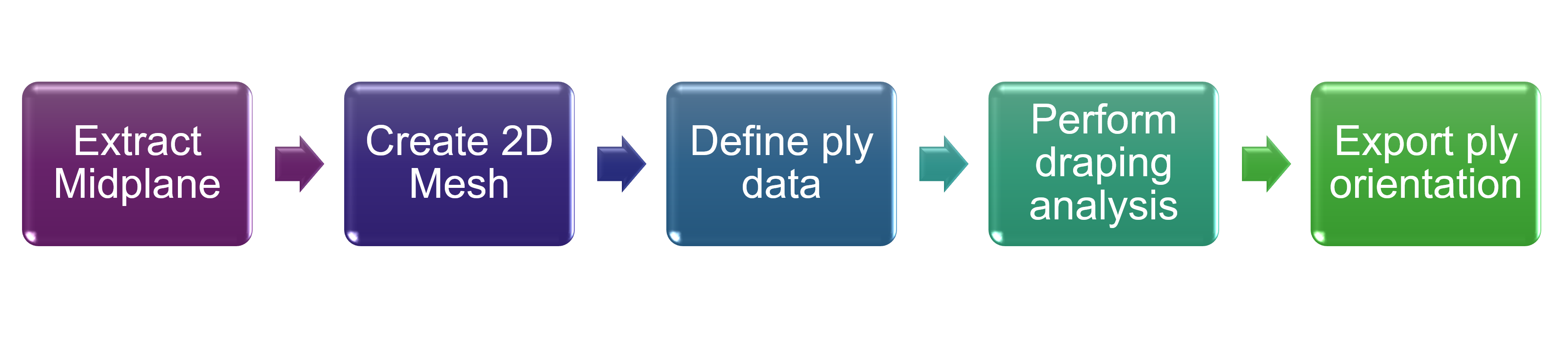

Draping Computations

Known Limitations in Draping Computation

- For complex models, the automatic midsurface extraction may fail. The workaround is to create the midsurface manually and Inspire will use that interface and not try to create one automatically.

- Inspire does not support post-processing of draping results.

Density

- Units: kg/m3

- Keyword: Density

- Description: Density of the preform. This the density of the fiber (glass, carbon. kevlar, etc.)

Specific Heat

- Units: J/(kg-K)

- Keyword: SpecificHeat

- Description: Specific heat of the preform

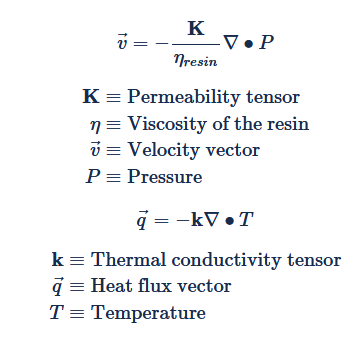

Thermal Conductivity Tensor

- Units: W/(m-K)

- Keyword: Conductivity_X, Conductivity_Y, Conductivity_Z

- Description: Thermal conductivity is tensor data, and it is supported in the local coordinate systems.

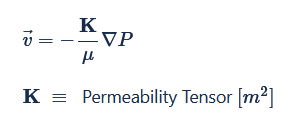

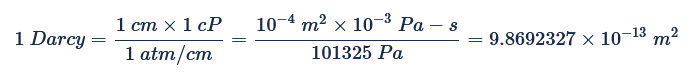

Permeability Tensor

- Units: m2

- Keyword: Permeability_X, Permeability_Y, Permeability_Z

- Description: Defined in Darcy's law for porous media. The oil mining industry uses a unit called Darcy which is physically more intuitive.

Porosity

- Units: None

- Keyword: Porosity

- Description: (1.0 - Fiber Volume Fraction). Often the industry is more familiar with the term Fiber Volume Fraction, and it is easy to determine.

Compressibility

- Units: 1/Pa

- Keyword: Compressibility

- Description: Used in VARTM analysis. This term has to be non-zero.

Pore Size (Diameter)

- Units: m

- Keyword: PoreSize

- Description: This is the average pore size of the preform. Needs a special flag to use this experimental feature, and it is not exposed in the GUI.