OS-T: 1070 Analysis of an Axi-symmetric Structure

In this tutorial the method of modeling an axi-symmetry problem in OptiStruct is covered.

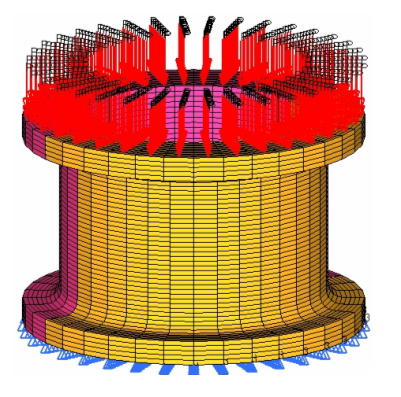

Figure 1. Full Model; Elements, Material, Props and BCs

Launch HyperMesh and Set the OptiStruct User Profile

Open the Model

Exercise 1: Analysis with the Full Model

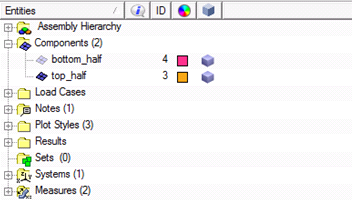

You will find that the structural model has already been set up with the necessary elements, boundary conditions, property, and material data so that it is ready to solve. Pressure load is applied on the top face of the geometry and constraints are defined at the bottom face. Note that the model is symmetrical about the z-axis and that loads and boundary conditions are symmetrical about the same axis as well. These represent the conditions necessary for modeling axi-symmetry problems. First, obtain the result for the full model and then you model a small part of the model with boundary conditions suitable to enforce the axi-symmetric behavior. Finally, you compare the results of the axi-symmetric model with the full model results.

Submit the Job

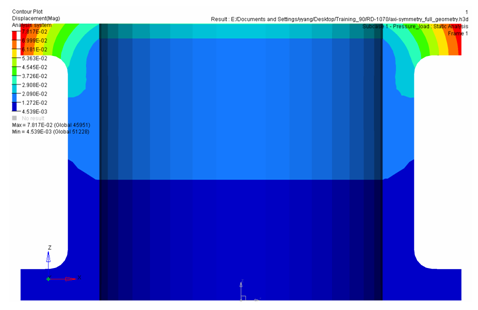

View the Results

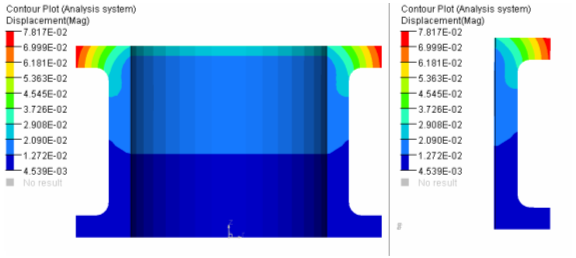

View the Displacements of the Structure

Exercise 2: Analysis with a Small Portion of the Full Model with Axi-symmetry Boundary Conditions

Set up the New Analysis

Return to HyperMesh to delete the all the elements, except for a small portion and to set up the axi-symmetry boundary conditions.

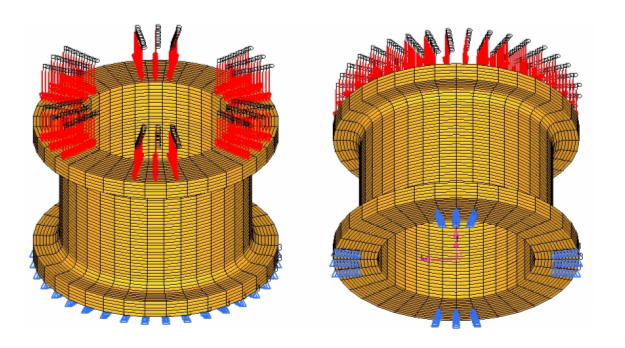

Figure 6. Left: Non Axi-symmetric Loads; Right: Non Axi-symmetric Boundary Conditions

Set up the Axi-symmetry Model

Apply the Additional Boundary Conditions

Create Constraints

Next you will submit the job, as was complete in Exercise 1.

to open the

to open the

to display the Left

view.

to display the Left

view.

to

enter the

to

enter the  .

. .

. to open the Load Model and

Results panel.

to open the Load Model and

Results panel. on the toolbar and load the

on the toolbar and load the

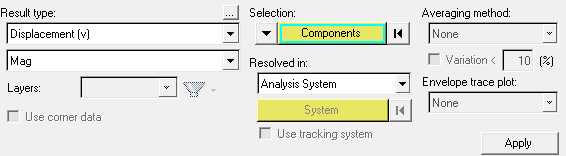

on the toolbar and contour the displacements.

on the toolbar and contour the displacements.