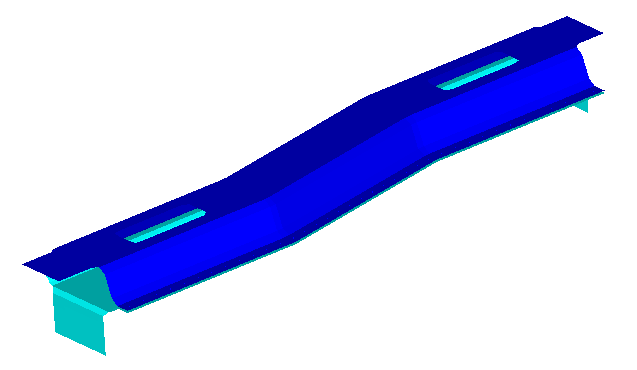

HL-T: 1050 Spot Weld (CBAR)

- Import a model to HyperLife

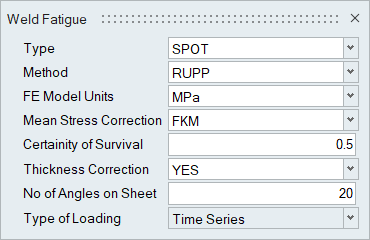

- Select the Weld module and define its required parameters

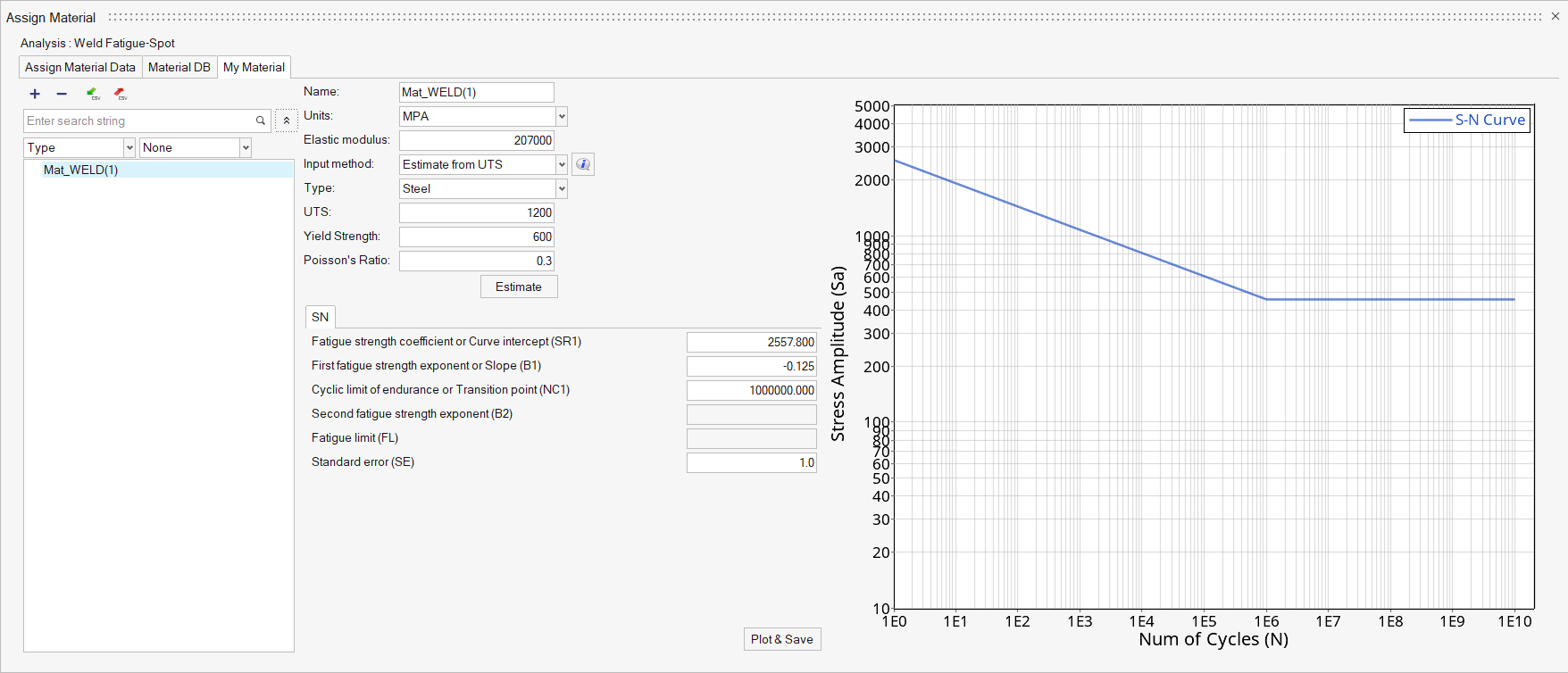

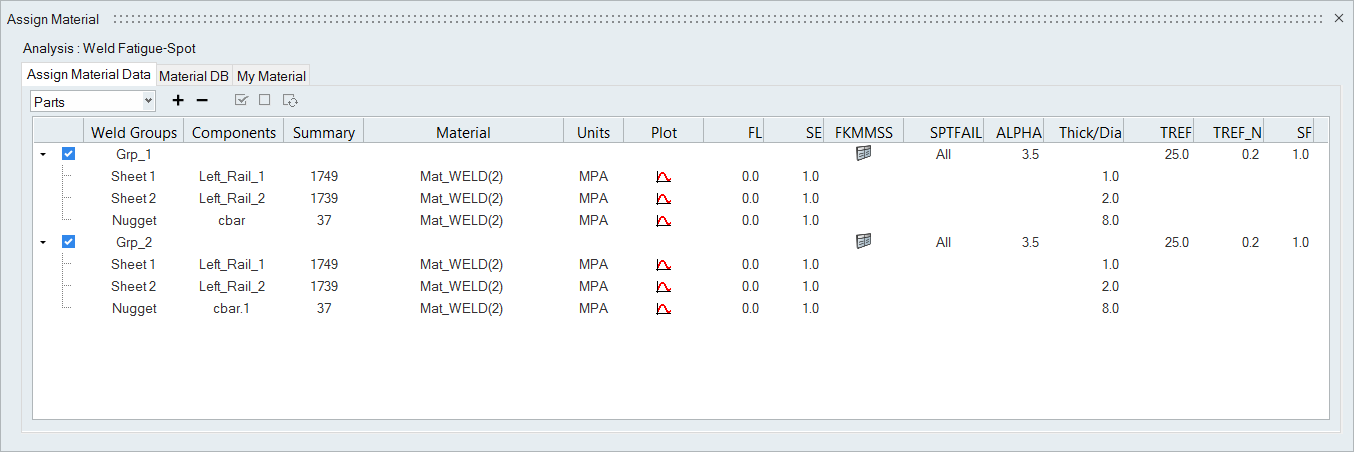

- Create a material and assign it to the welds and sheet groups

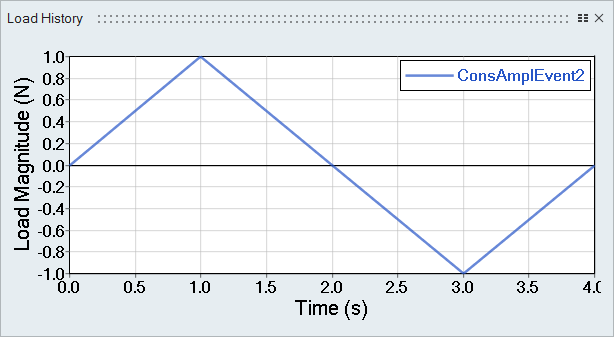

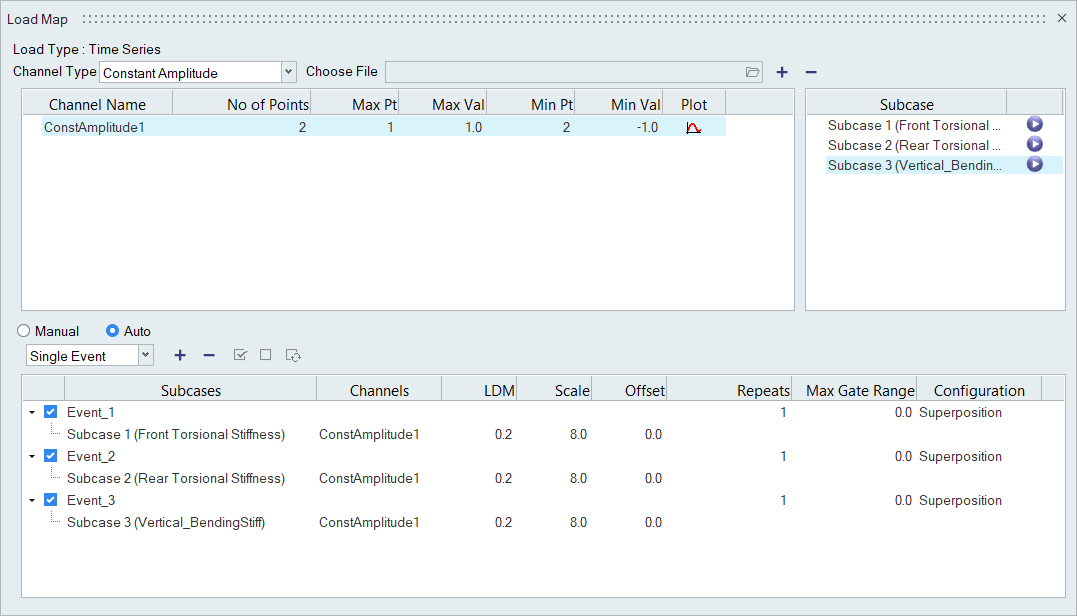

- Assign load histories for scaling the stresses from FEA subcases

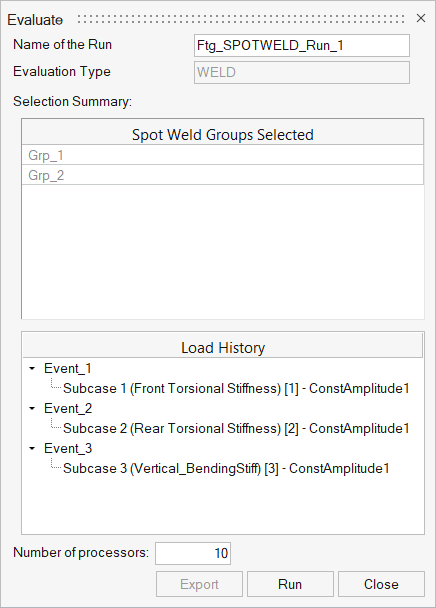

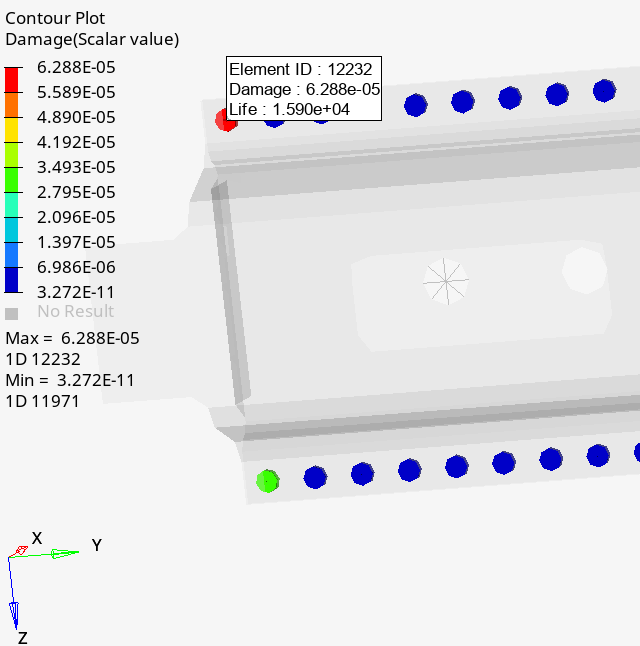

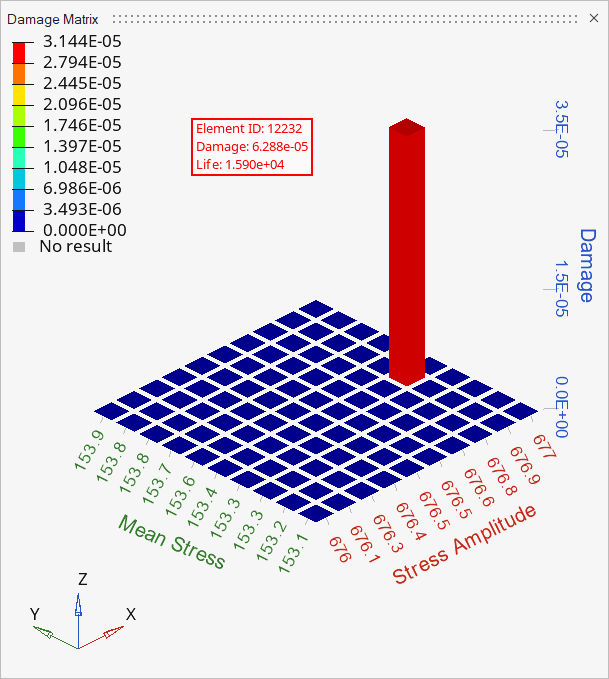

- Evaluate and view results

- HL-1050\Rail_SpotWeld.h3d

- HL-1050\Rail_SpotWeld.force

Import the Model

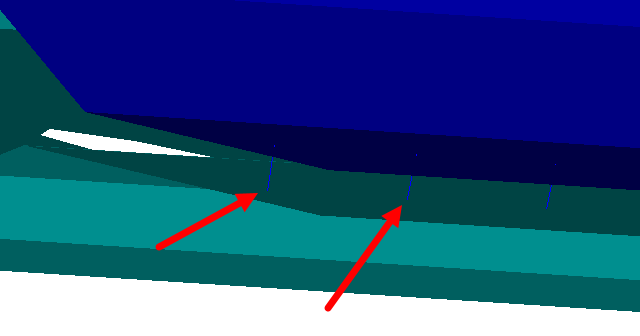

ELFORCES are required for this analysis.