Tutorial: High Pressure Die Casting

Set up a high pressure die casting simulation and see how to troubleshoot it.

In this exercise, you will learn how to run an analysis and prevent typical casting defects for the high pressure die casting process.

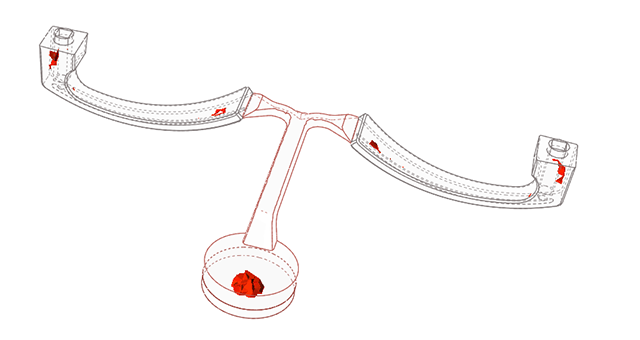

Model file is available in the tutorial_models folder in the installation directory in Program Files\Altair\2021.1\InspireCast2021.1\tutorial_models\handle.x_b.

Import Geometry

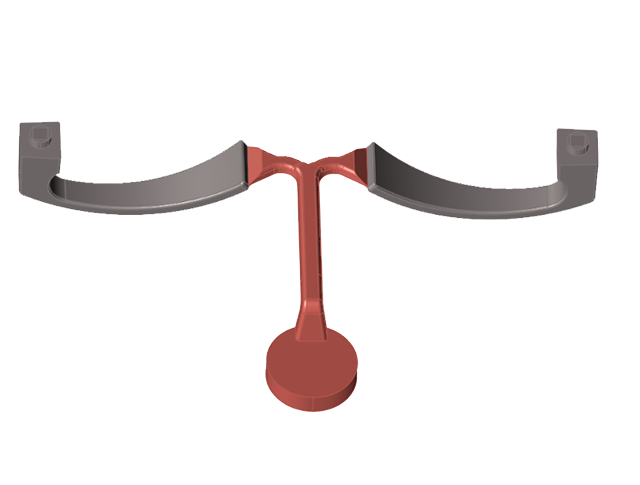

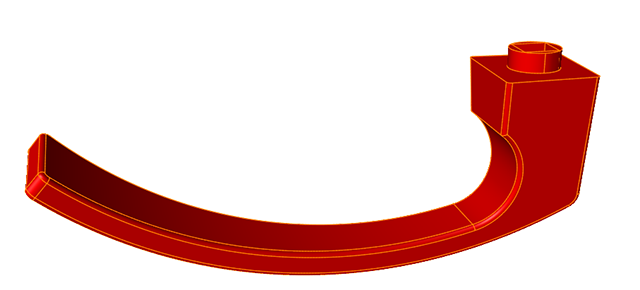

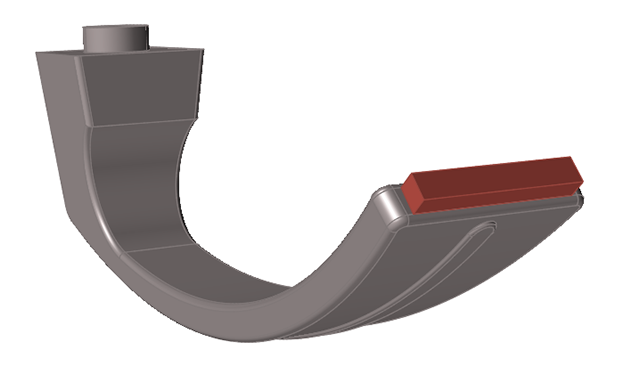

Designate a Cast Part

Create an Ingate

Create a Mold

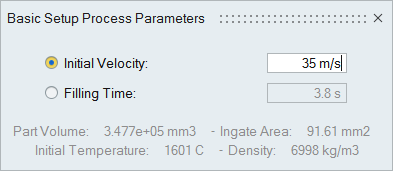

Configure Basic Setup

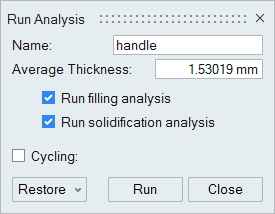

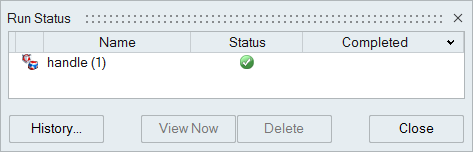

Run Analysis

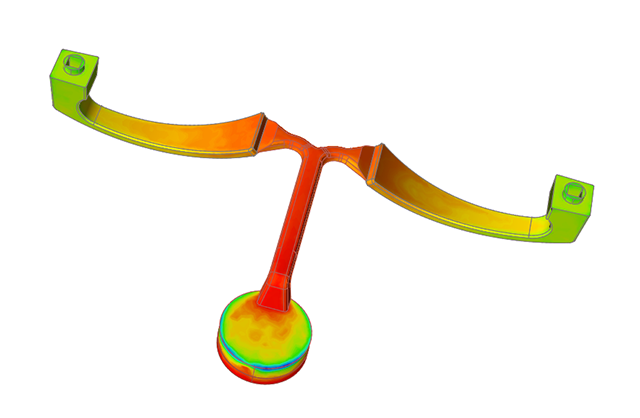

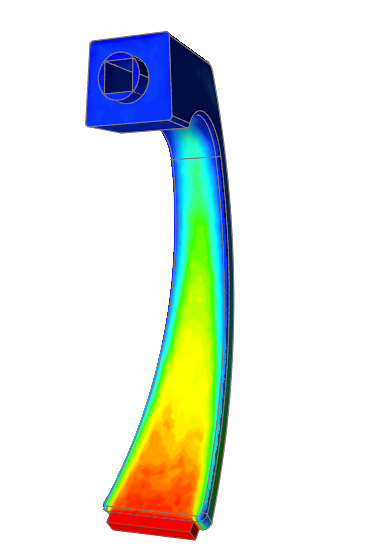

Run the Temperature Animation

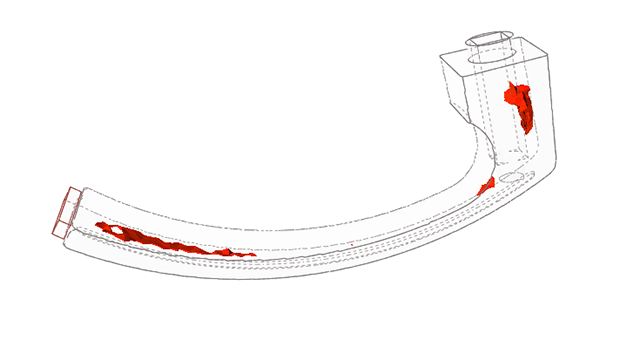

Run the Porosity Animation

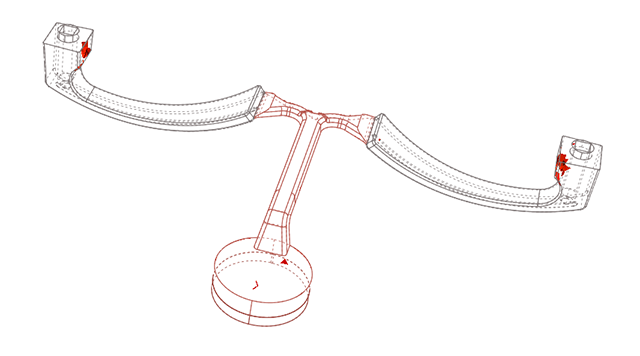

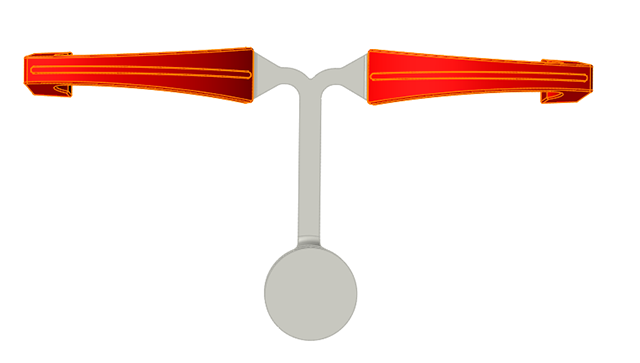

- To avoid defects like trapped air, we can optimize the design and use a

runner system.

- To avoid porosity, we will add additional components which act as vents to

collect the trapped air.

Open the New Model

- Click File>Open.

- Browse to and select <installation directory>\tutorial_models\handlefull.x_b

Cast Material and Temperature

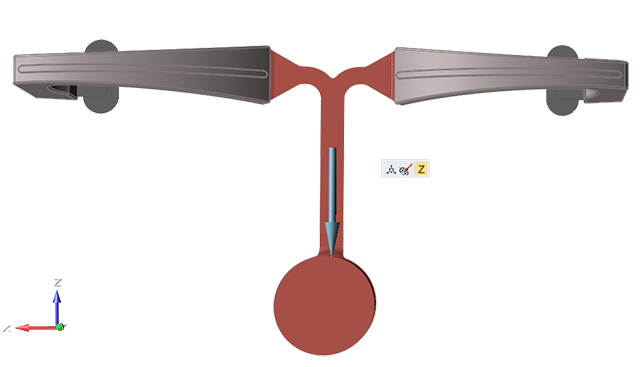

Set Gravity Direction

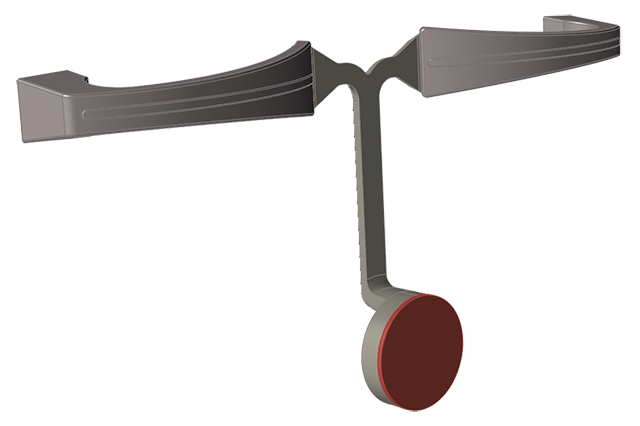

Designate Surfaces as Gates

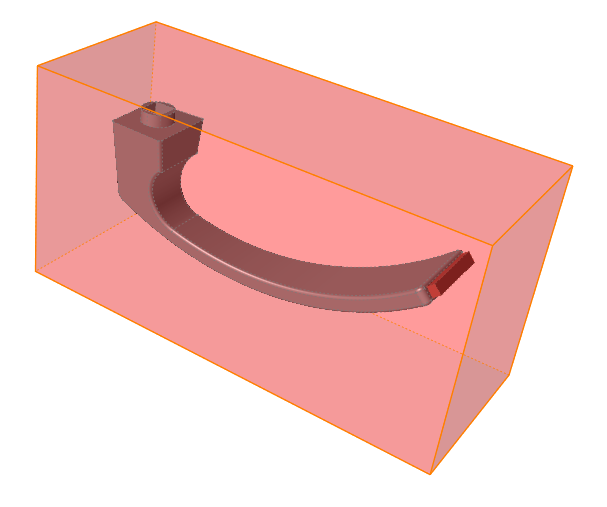

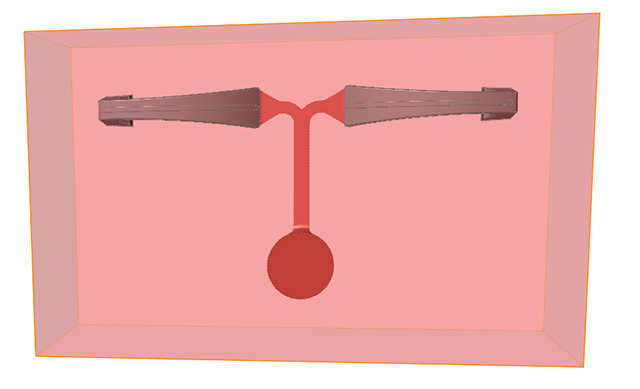

Generate a Mold

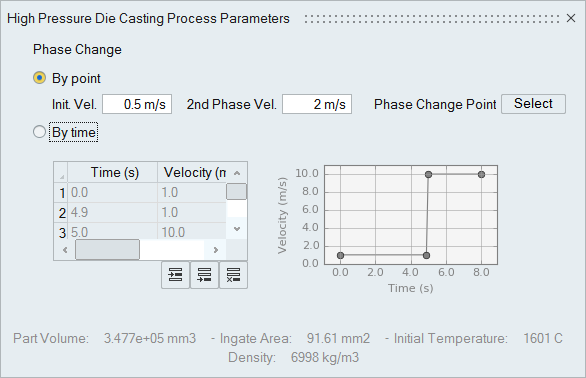

Configure High Pressure Parameters

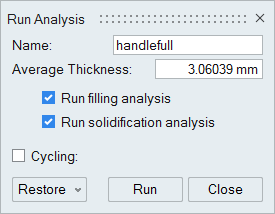

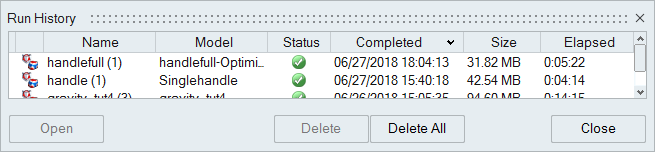

Run Analysis

Run the Temperature Animation

View Last Air Result

to select the

to select the