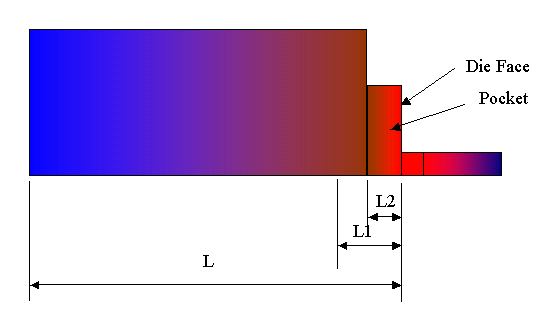

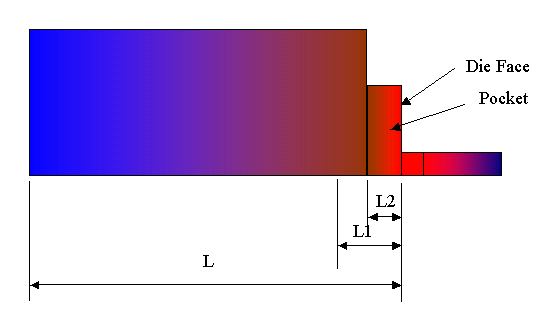

L = Billet Length

L1 = Butt Length (Typically 0.5 inches)

L2 = Pocket Length

Flat die without pockets (L2 = 0)

| • | Extrusion direction should be positive Z-axis. |

| • | Mesh such that Z=0 at the front end of the billet. |

| • | If L1 is the butt length, define a mesh such that it has at least two elements in between Z = 0 (die face) and Z = -L1/2. These elements will not move during the analysis. |

Flat die with pockets (L2 > 0)

| • | Extrusion direction should be positive Z-axis. |

| • | Mesh such that Z=0 at the front end of the billet. |

| • | If L1 is the butt length, define a mesh such that it has at least two elements in between Z = 0 (die face) and Z = -L1/2. These elements will not move during the analysis. |

Hollow Die

| • | Extrusion direction should be positive Z-axis. |

| • | Mesh such that Z=0 at the front end of the billet. |

| • | If L1 is the butt length, define a mesh such that it has at least two elements in between Z = 0 (die face) and Z = -L1/2. These elements will not move during the analysis. |

| • | Collapsed elements in the billet become very thin in the extrusion direction. This might lead to bad element-grading in the butt area. Therefore, it is advisable to occasionally refine elements in L1 area in the Z-direction. |

| • | If using higher-order elements (Hex20 or Hex27), Butt's boundary should match element faces (element faces should fall at Z= -L1). |

See Also:

Guidelines for Simulation