Material Properties

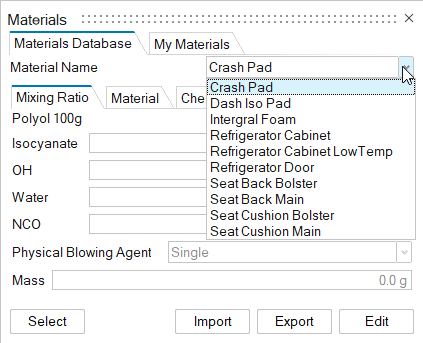

Material properties are accessible from the Materials Database and My Materials tabs in the Materials dialog.

Materials Database Tab

The Materials Database tab lists the materials included with Inspire PolyFoam. The tab also provides access to properties that you can review and modify for each material. You can save any modified materials as new materials and access them and their properties through My Materials tab.

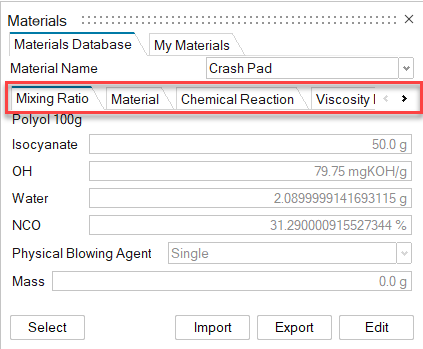

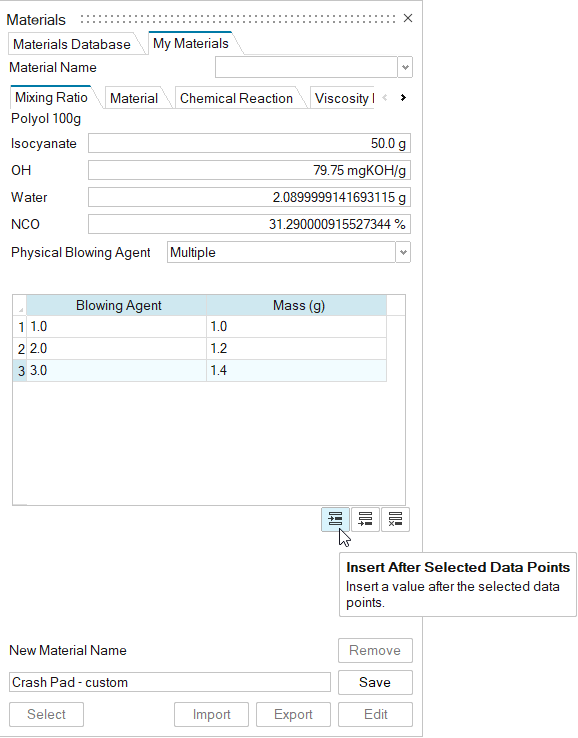

Mixing Ratio Tab

The Mixing Ratio tab includes the following material properties:

| Property | Description |

|---|---|

| Isocyanate | Mixing ratio = Polyol (100g): Isocyanate [g] |

| OH | Quantity of KOH [mgKOH/g] |

| Water | Mass of water [g] |

| NCO | Percentage of NCO in the polyisocyanate by weight [%] |

| Physical Blowing Agent | Mass of physical blowing agent [g] |

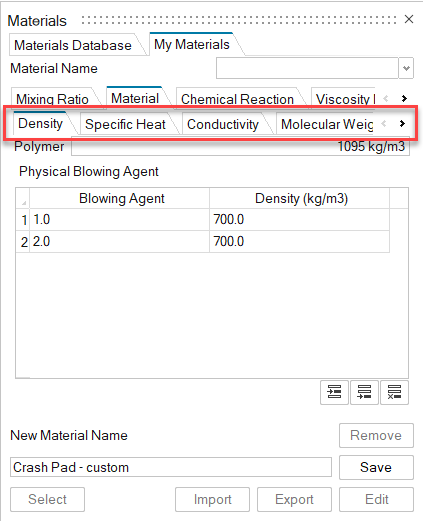

Material Tab

The Density subtab includes fields for the polymer and each physical blowing agent.

The Specific Heat and Conductivity subtabs include fields for the polymer, CO2 gas, and each physical blowing agent (liquid and gas).

The Molecular Weight and Boiling Temperature subtabs includes fields for each physical blowing agent.

Chemical Reaction Tab

The Chemical Reaction tab includes a second row of tabs to define properties for Reaction Type, Isocyanurate Reaction, Gelling, Chemical Blowing, Physical Blowing, Gelling Ratio and CO2 Saturation. These properties include:

| Property | Description |

|---|---|

| Type | Reaction type can be set to Reversible or Irreversible. |

| Isocyanurate Reaction | Isocyanurate reaction can be set to Enabled or Disabled. |

| A | Pre-exponential factor expressed in 1/s. |

| E | Activation energy of the chemical reaction expressed in J/(g mol). |

| dH | Heat generation/dissipation of the chemical reaction expressed in J/(g mol). |

| Temperature | Temperature to start the gelling reaction. |

| Order of Reaction | Order of the reaction in reaction kinetics. |

| Ratio | OH conversion at gelling point for the entire foam part. |

| Fluid Critical Ratio | OH conversion at gelling point for individual cells. |

| Saturation | The saturation level defines the initial mass of the CO2 that is dissolved in the polyurethane's mass. Saturation is related to cream time. |

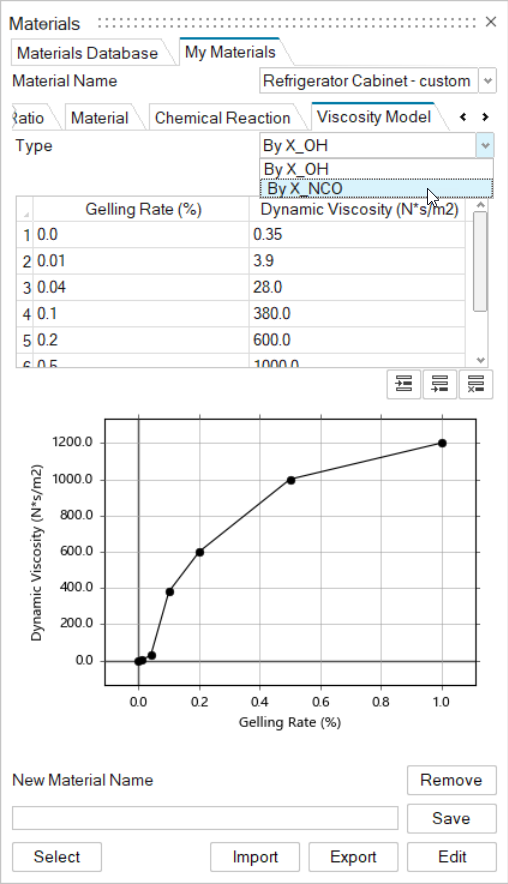

Viscosity Model Tab

Foam Rheology Model Tab

The Foam Rheology Model tab includes three rheological models: Carreau, Bingham and Power-Law. Choose the model that is appropriate for your material and define the exponent, viscosity and constant.