SS-T: 4010 Structural Non-linear Analysis

Run structural non-linear analysis in SimSolid.

Purpose

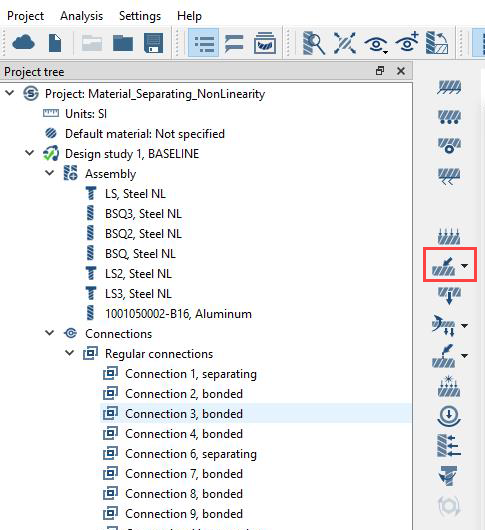

- Create structural non-linear analysis (material and contact).

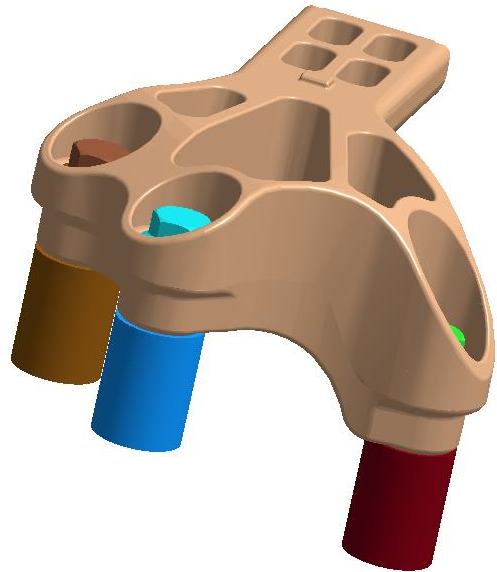

Model Description

- Material_Separating_NonLinearity.ssp

- Stress_strain_curve.csv

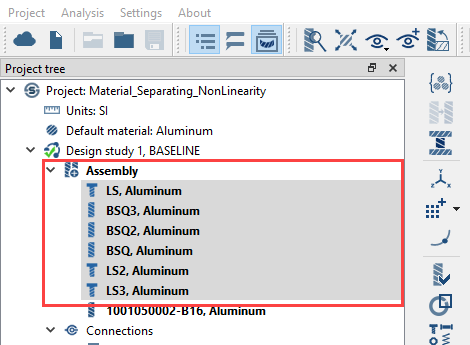

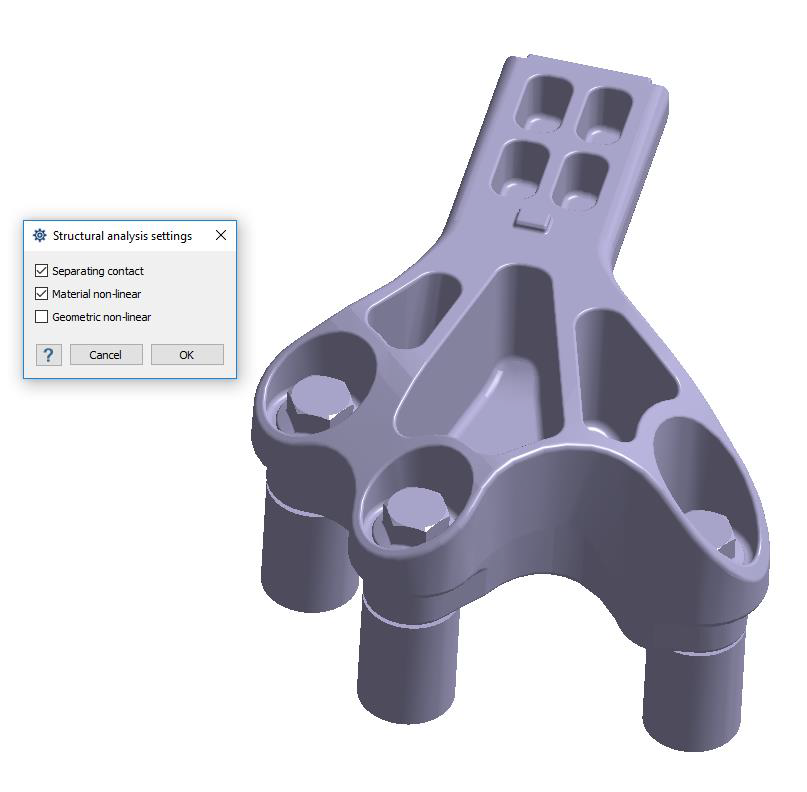

Figure 1.

- Material is set to Aluminum for all parts.

- Regular connections with 0.6mm gap and 0.3mm penetration tolerance.

- For the sake of analysis, all sliding contacts have been changed to bonded.

Open Project

Open the SimSolid project file.

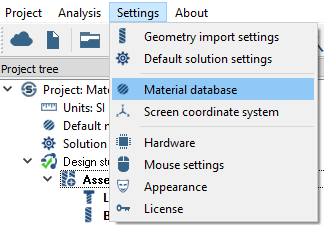

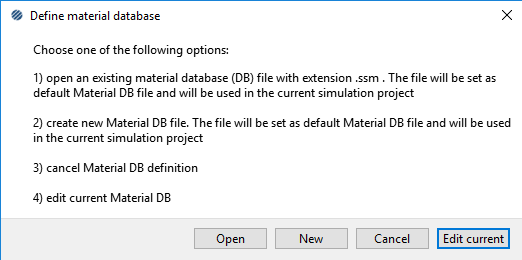

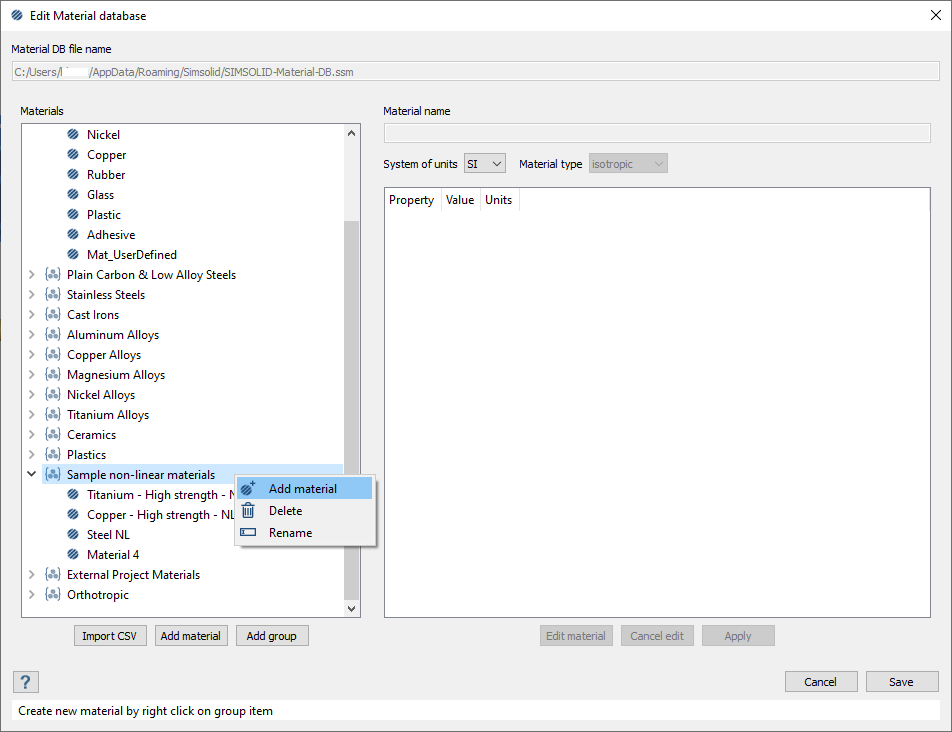

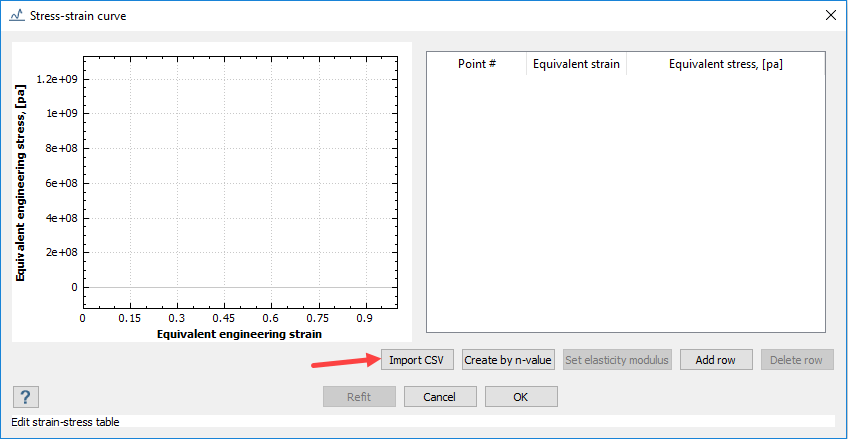

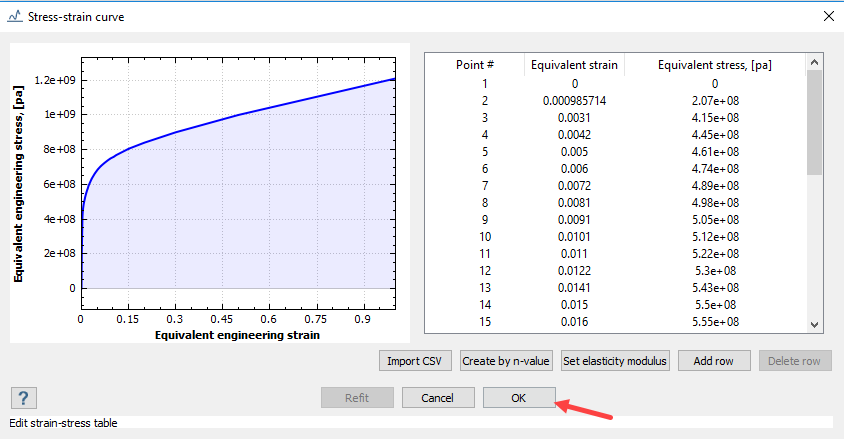

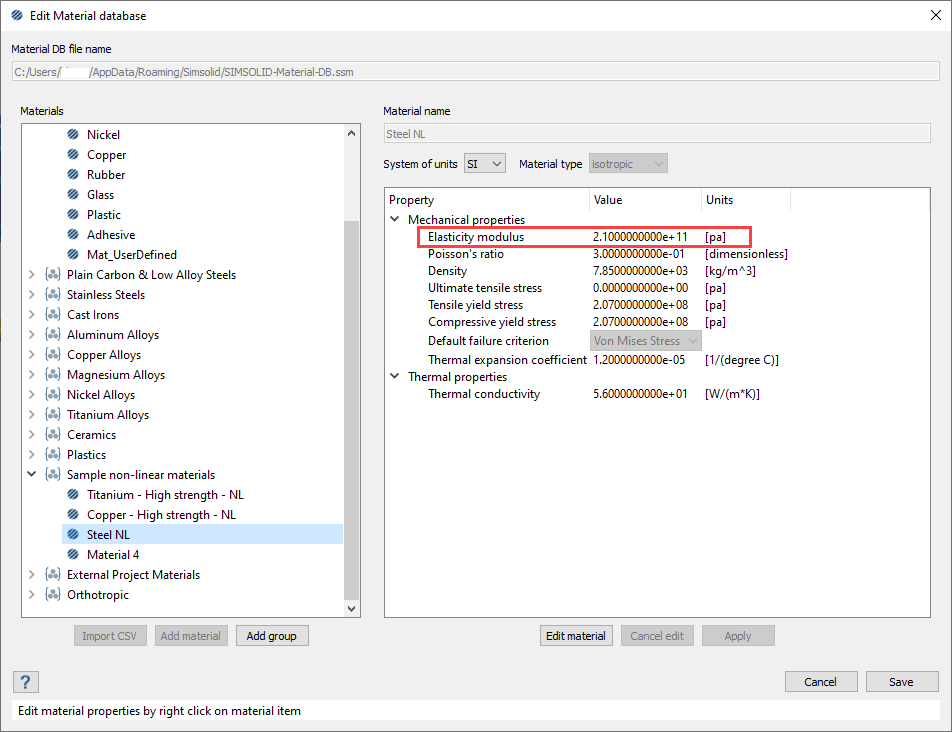

Define Non-linear Material

Edit the material database to define non-linear material.

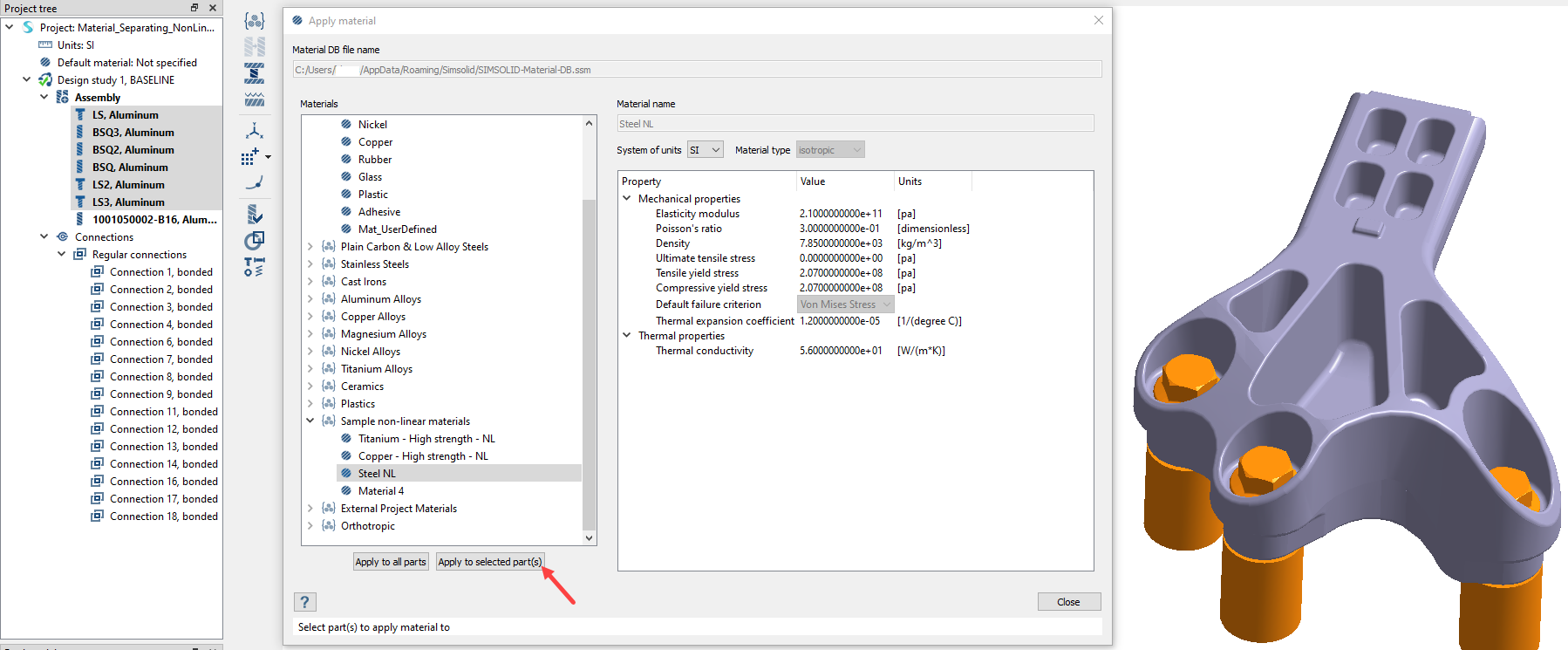

Assign Materials

Apply materials to select parts in the assembly.

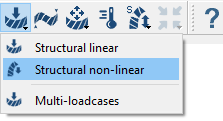

Create Structural Non-linear Analysis

Setup non-linear separating contact and material non-linear subcases.

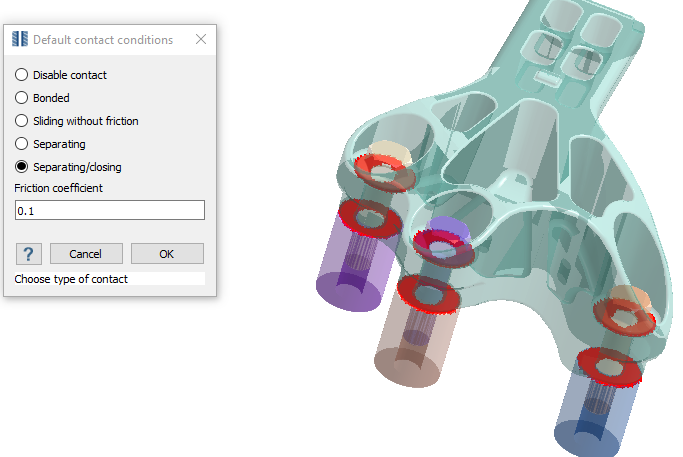

Edit Contact Conditions

Change the contact conditions to separating/closing.

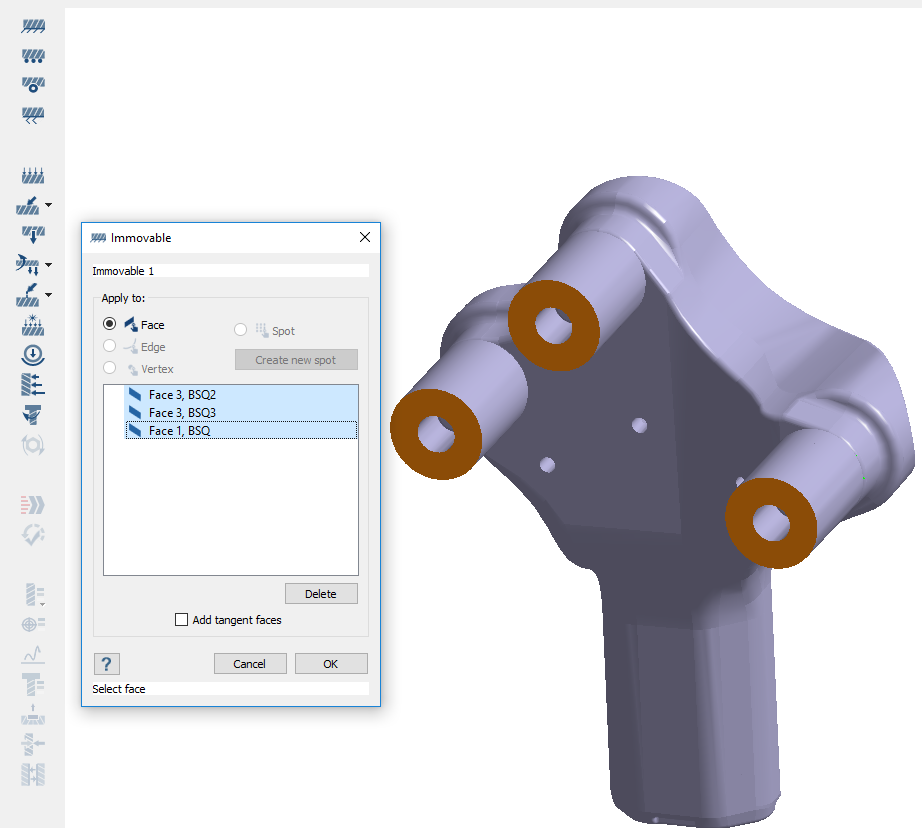

Create Immovable Support

Create immovable support.

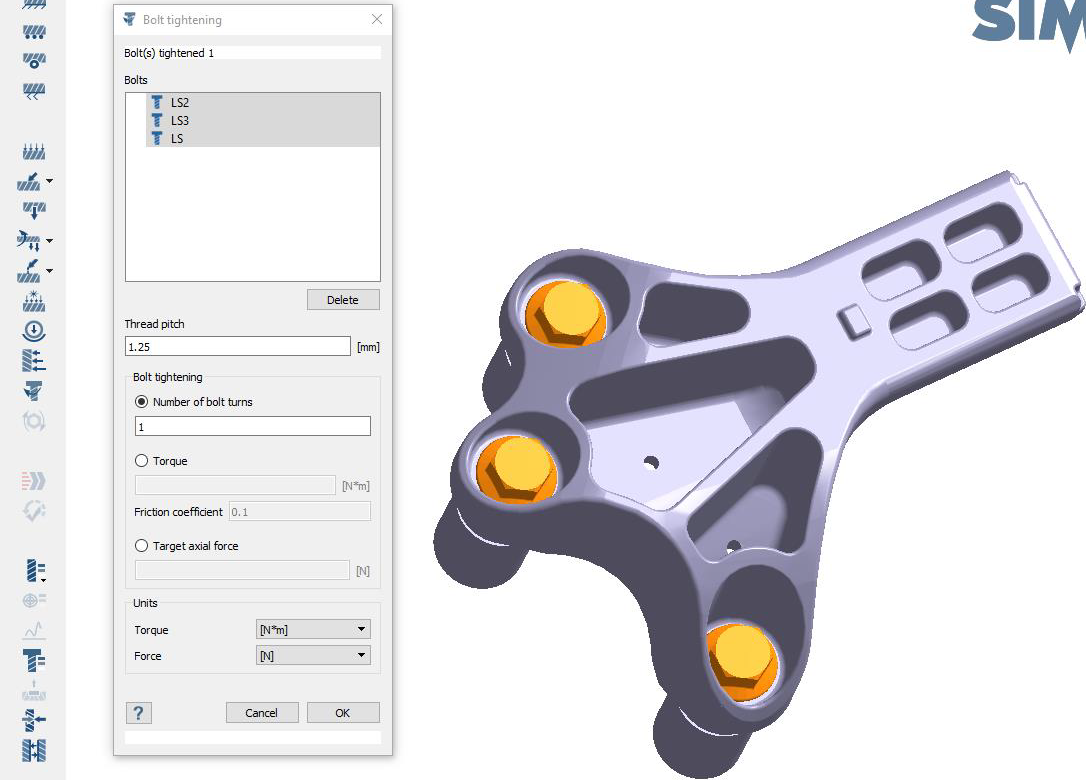

Tighten Bolts

Create a bolt tightening load.

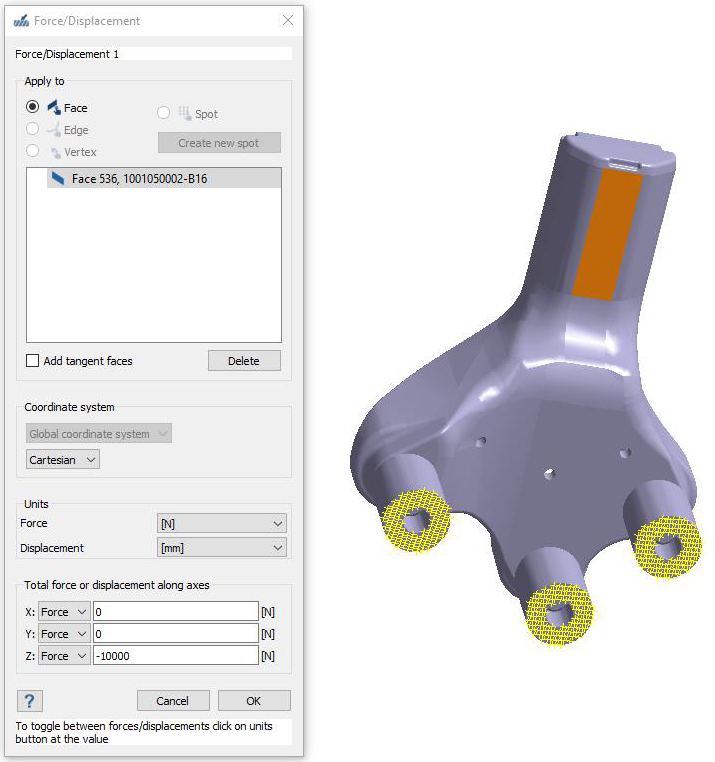

Define Load

Apply Force load.

Run Analysis

Solve the analysis.

- In the Project Tree, open the Analysis Workbench.

-

Click

(Solve).

(Solve).

Review Results

Plot the displacement contour.

Review Bolt Forces

View a table showing bolt forces in the analysis.

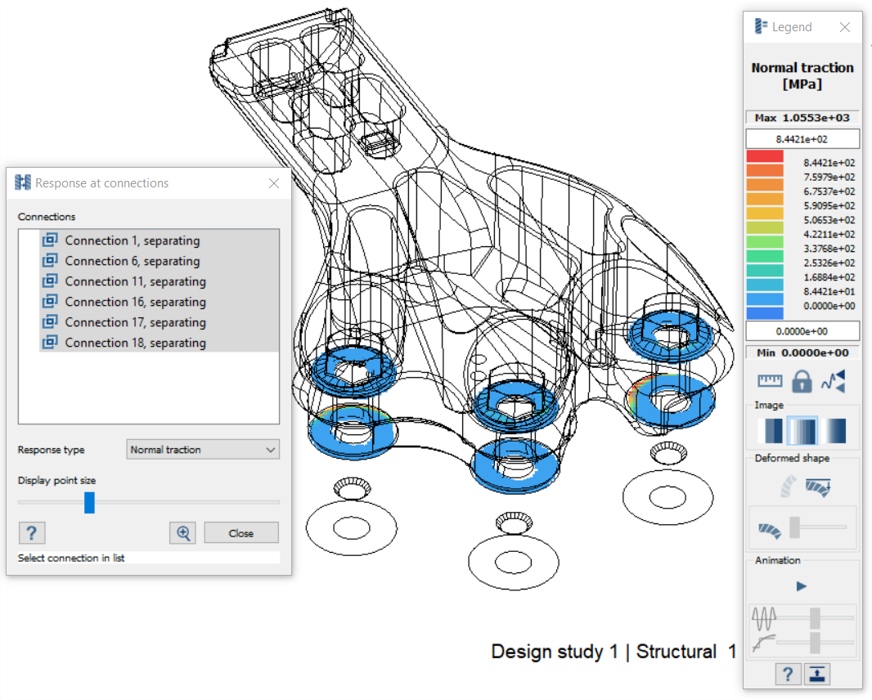

Review Contact Response

View a table showing contact response (opening, slippage, and traction at contacts).

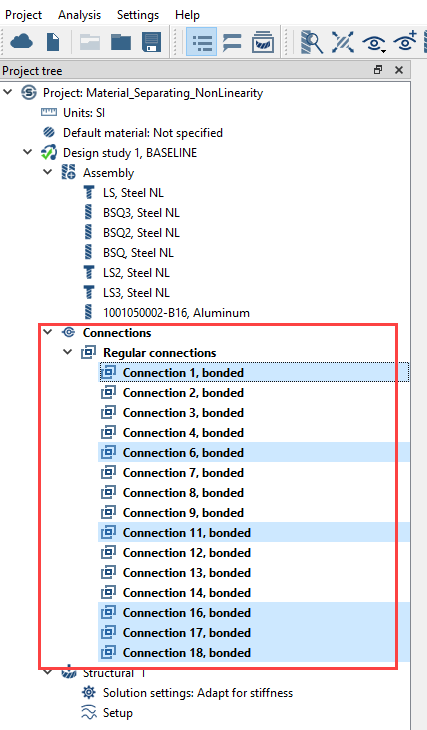

Figure 19.

Figure 19.