SS-T: 4060 Frequency Response Analysis

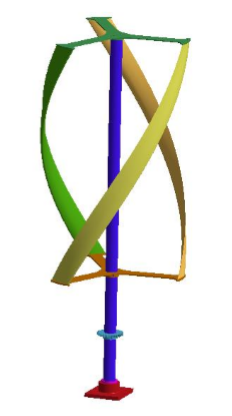

Create frequency response analysis in SimSolid for a vertical wind turbine assembly.

Purpose

- Use modal analysis results to create a frequency response analysis.

Model Description

Figure 1. Wind turbine model

- Frequency.ssp

- Material is set to Steel for all parts.

- Regular connections - 3mm gap and penetration tolerance.

- SimSolid automatically creates bonded contact conditions.

Open Project

Open the SimSolid project file.

Create Modal Analysis

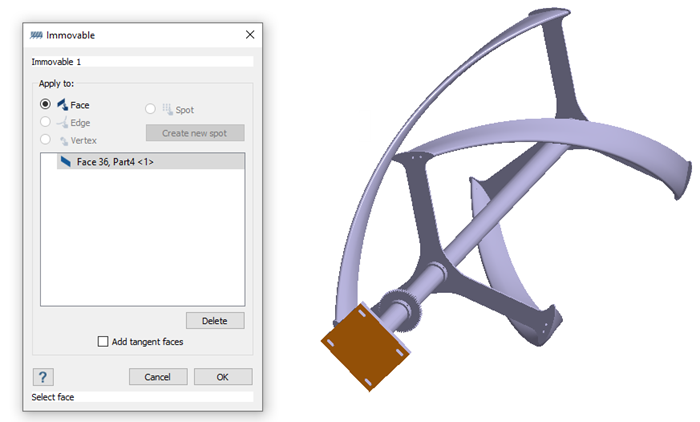

Create Immovable Support

Create immovable support.

Run Analysis

Solve the analysis.

- In the Project Tree, open the Analysis Workbench.

-

Click

(Solve).

(Solve).

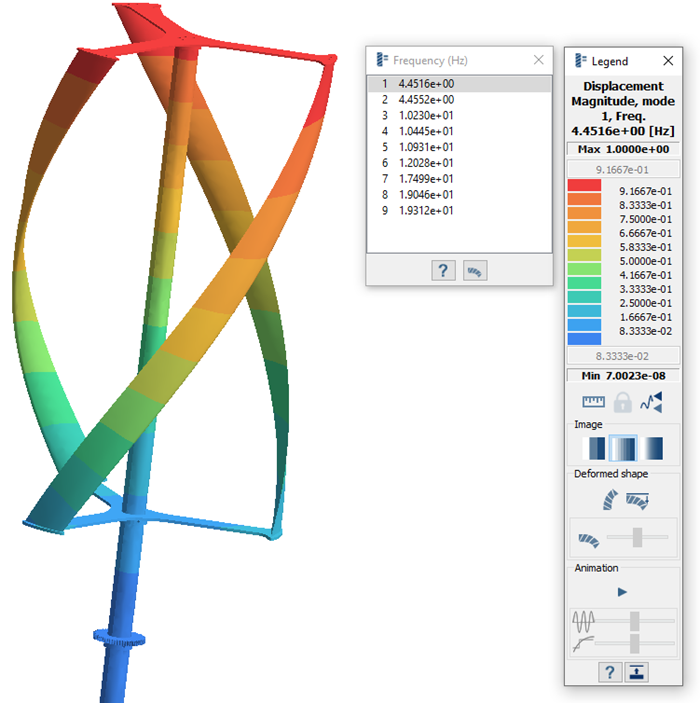

Review Modes

Plot the Displacement Magnitude contour and review the modes.

Create Frequency Response Analysis

Use modal results to create frequency response analysis.

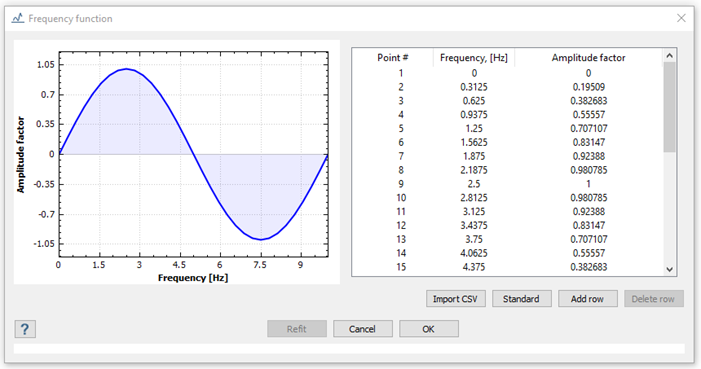

Define Frequency Function

Define a standard frequency function for the analysis.

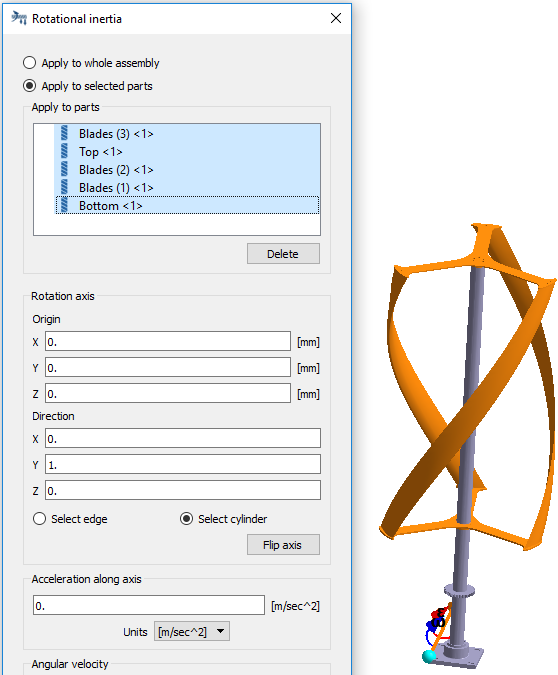

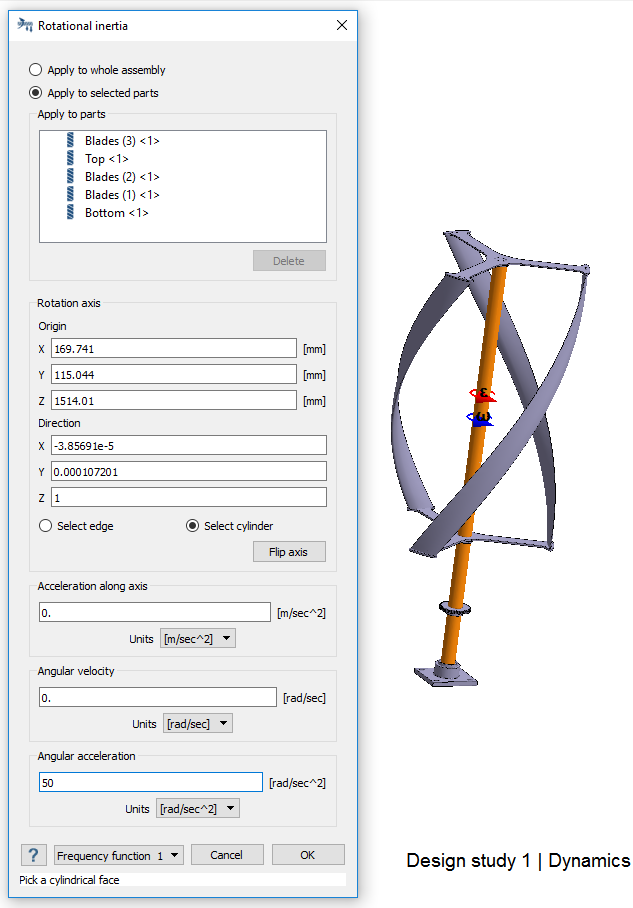

Define Loads

Add rotational inertia loads.

Run Analysis

Solve the analysis.

- In the Project Tree, open the Analysis Workbench.

-

Click

(Solve).

(Solve).

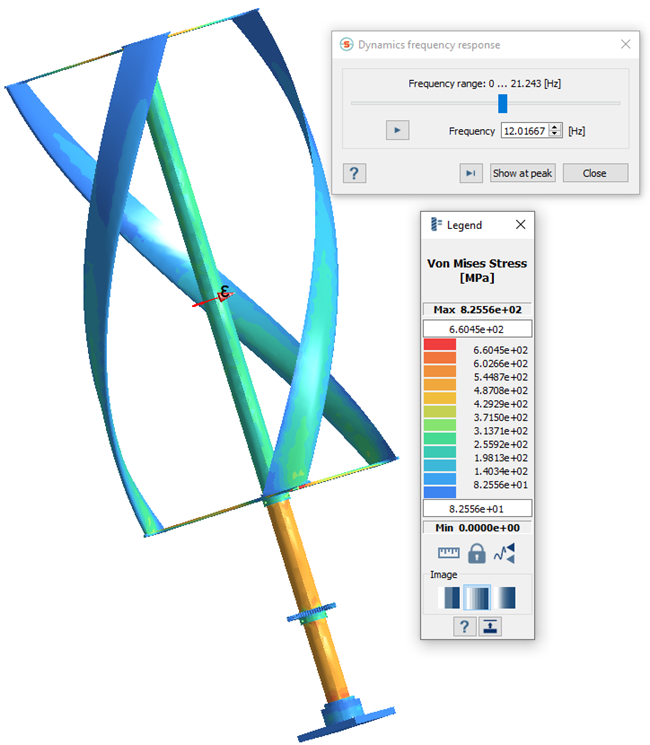

Review Results

Plot Von Mises stress contour and view animations.