What Is Inspire PolyFoam?

Inspire PolyFoam is an essential toolset to simulate and validate the part design and physical processes that are required to create a polyurethane foam part.

Inspire PolyFoam Highlights

Inspire PolyFoam helps you determine an ideal part design, material usage and manufacturing process before the physical production of a foam part begins.

- Precision tools help you define material properties, injection, flow and foaming stages for rigid, flexible or semi-rigid polyurethane foam.

- A one-click pouring cup test characterizes material behavior for common cavity shapes including cones, cubes and cylinders.

- Process simulation helps you detect problems with material pouring, filling, expansion and formation.

Optimized Five-Step Simulation Workflow

- Import CAD geometry and designate the part you want to create.

- Define the nozzle and path for the material injection.

- Designate the mold and tooling such as Velcro, inserts, guiders and vents.

- Define the simulation parameters for the mold and material.

- Run the simulation.

Component Creation and Editing

- Parts: Designate your foam part from existing CAD geometry; easily make modifications through Inspire.

- Nozzle: Define a nozzle size, foam injection direction, mass flow rate, material-flow start and end times, and nozzle travel paths for releasing the foaming chemicals into the mold.

- Tooling: Designate the Velcro, inserts and guiders; define the mold geometry and parting lines; add vents to the mold for optimal part formation.

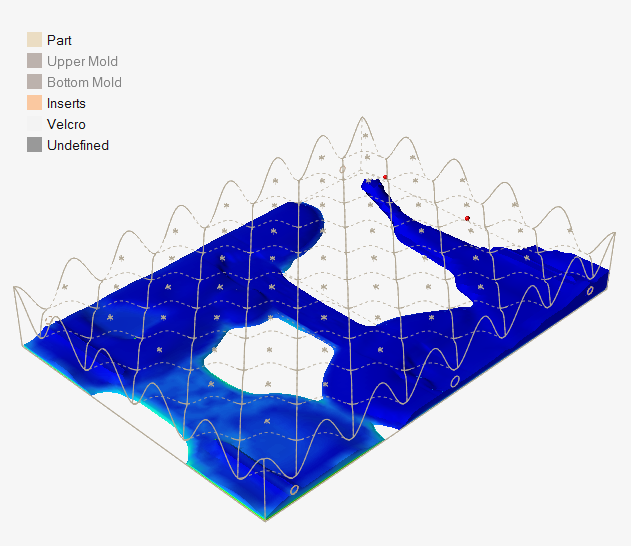

Material Flow Visualization

- Use the legend to easily hide or display parts and tooling to review the model content.

- Use animation controls to visualize the evolution of material flow in the mold cavity.

- View temperature, pressure, density and velocity distribution at specific points in the mold cavity.