Result Types

A set of result types is available for each of the four analysis stages: injection, foaming, curing and defects.

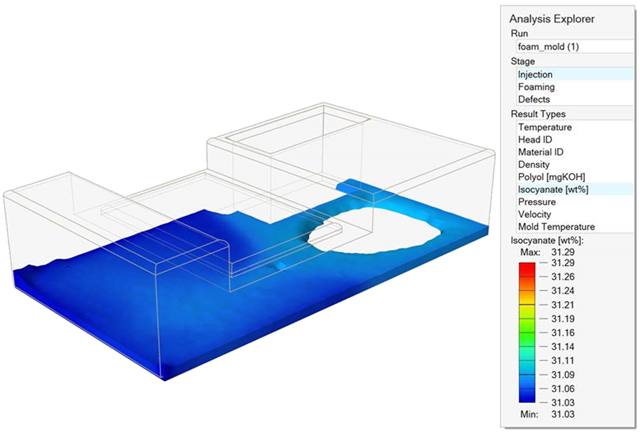

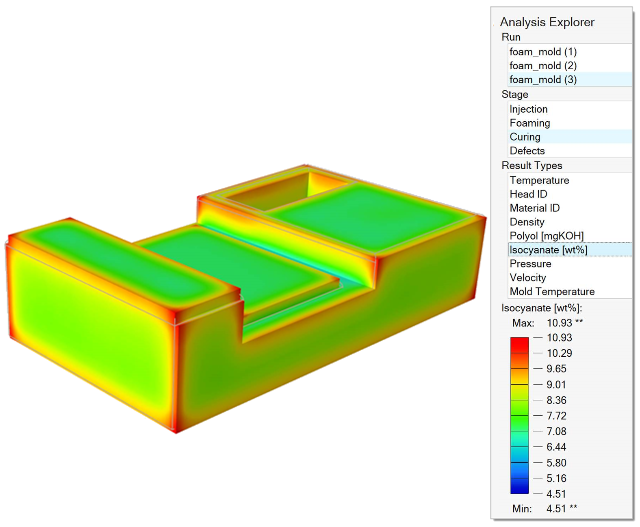

Injection Results

Review material behavior through the injection stage. Result types for this stage include: Temperature, Head ID, Material ID, Density, Polyol [mg KOH], Pressure, Velocity, Mold Temperature, Isocyanate [wt%], and Viscosity.

| Result Type | Description |

|---|---|

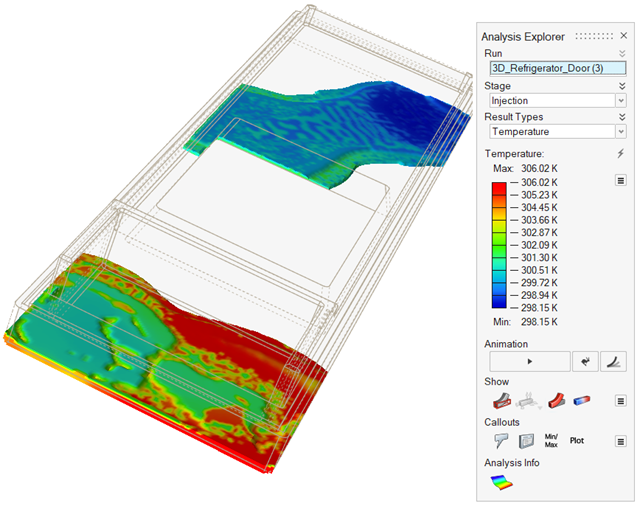

| Temperature | Review the temperature evolution of the material entering the

part cavity. Check regions for excessive heating or cooling.

Determine the appropriate fill speed for uniform temperature

distribution. |

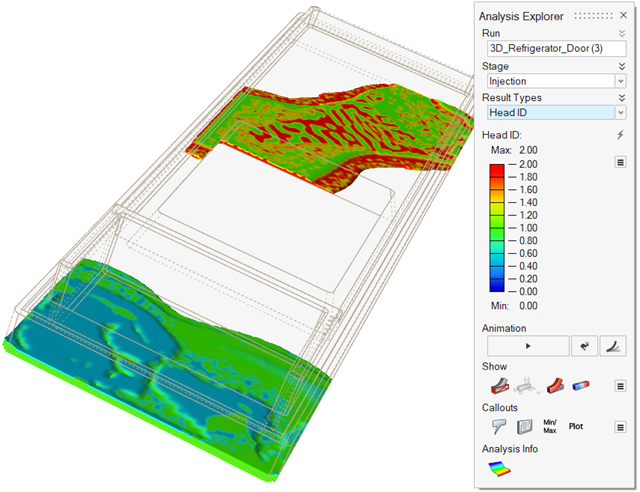

| Head ID | Review injection results for material coming from a

particular nozzle. |

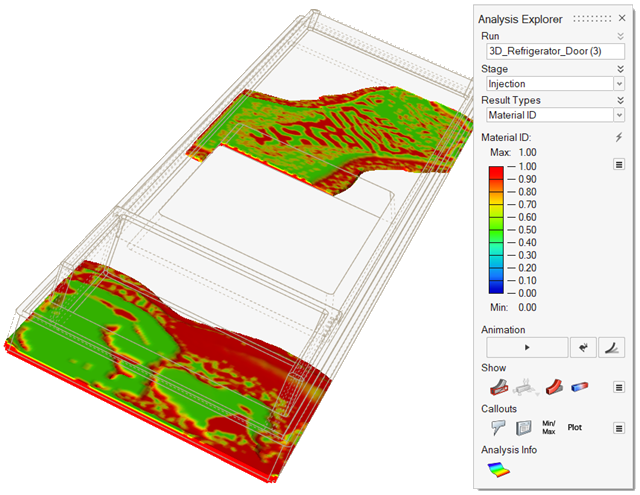

| Material ID | Review results for a particular material. Click the

Show and

Options buttons to change to

velocity, contour-fill animation. |

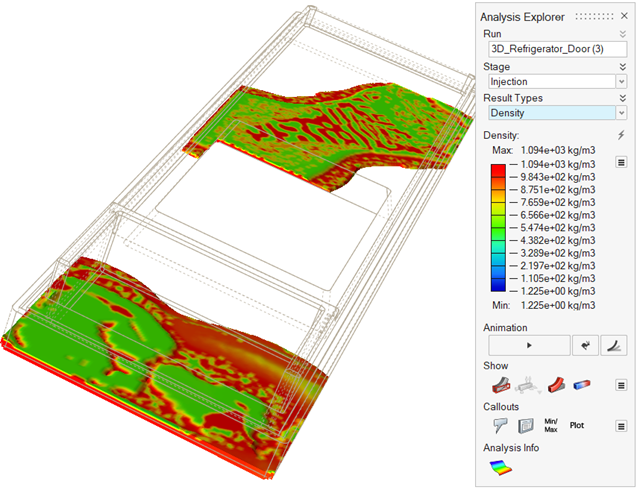

| Density | Consider material density through the progression of the

injection stage. |

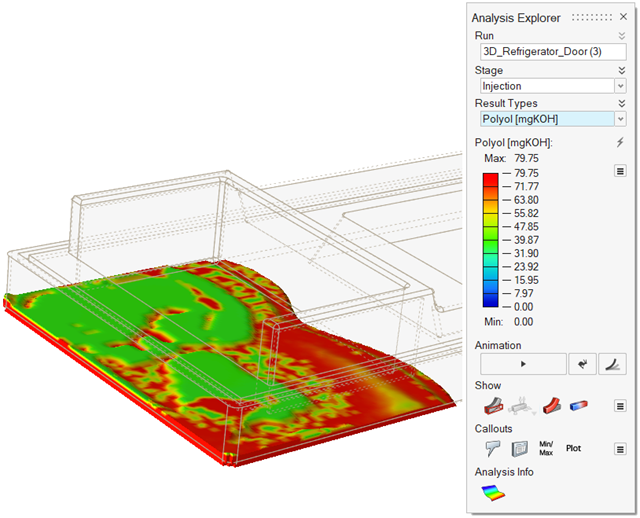

| Polyol [mg KOH] | Review the levels of polyol that remain in the

material. |

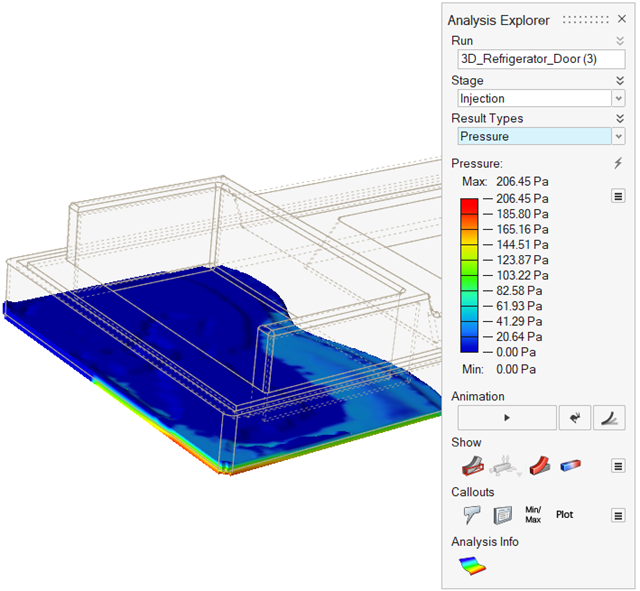

| Pressure | Review the impact of pressure on the material during the

injection stage. |

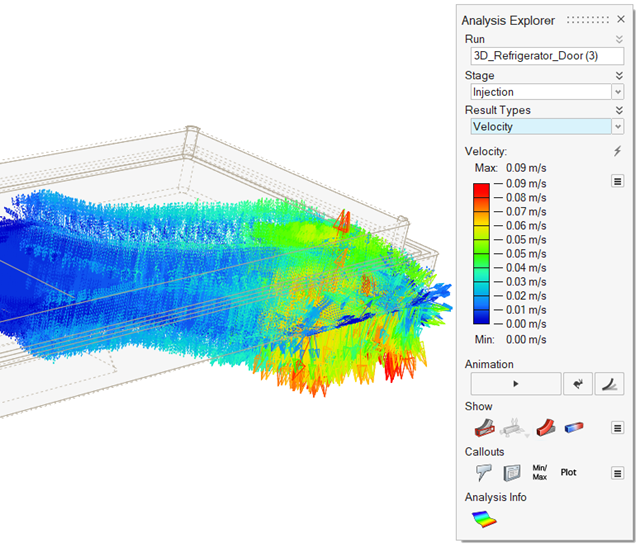

| Velocity | Review the filling process, which is represented with

vectors, to detect turbulences and velocities in the

material. |

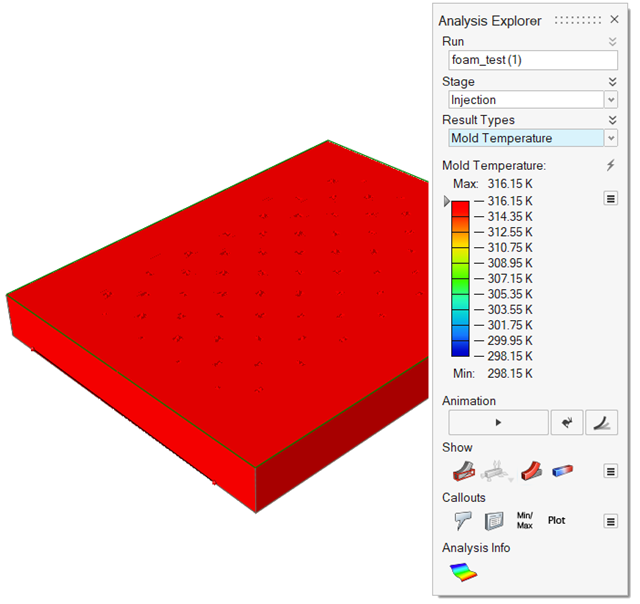

| Mold Temperature | Review the temperature variance in the mold throughout the

injection stage. |

| Isocyanate [wt%] | Review the of isocyanate levels that remain in the

polyurethane material. |

| Viscosity | Review the dynamic viscosity of the polyurethane material. |

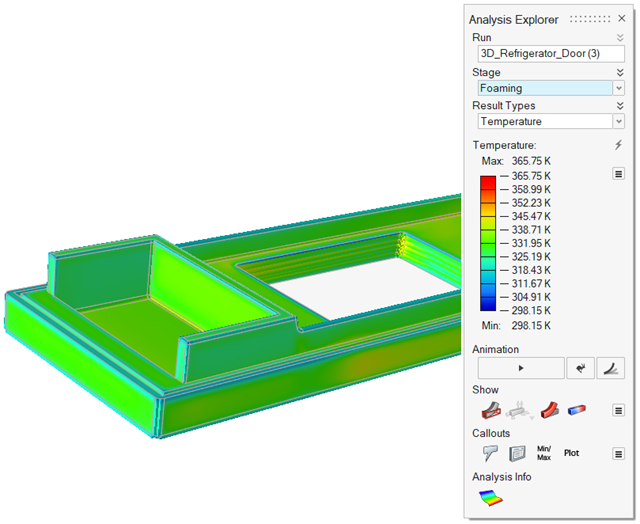

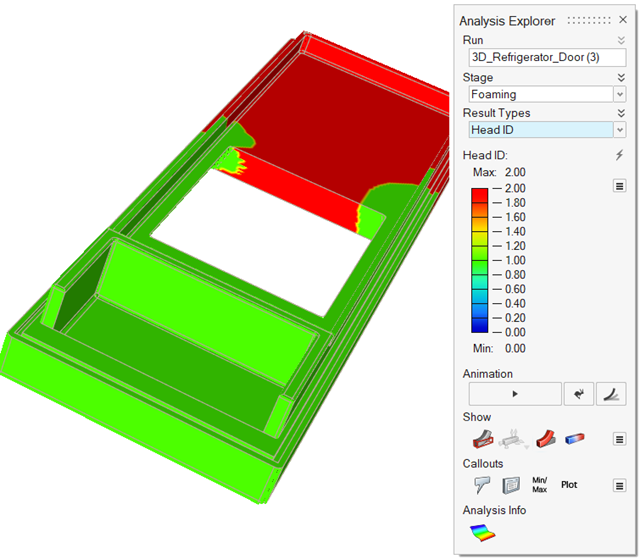

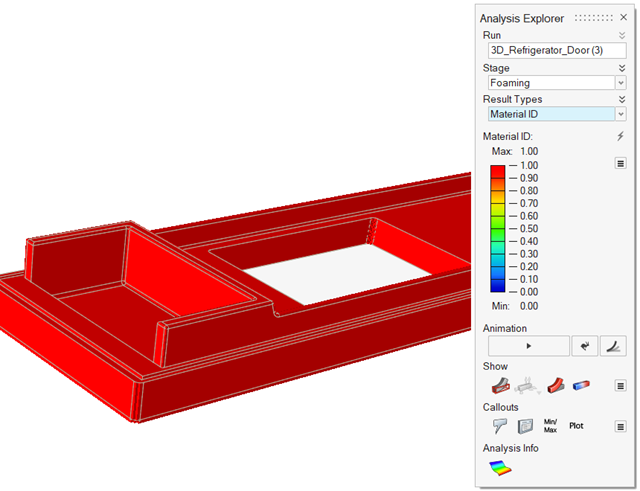

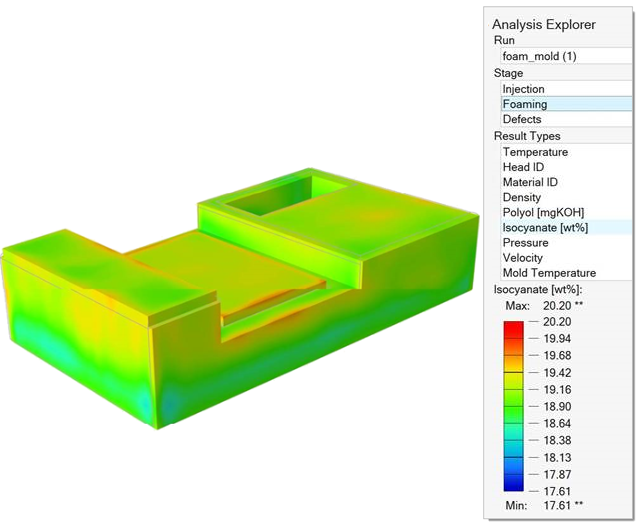

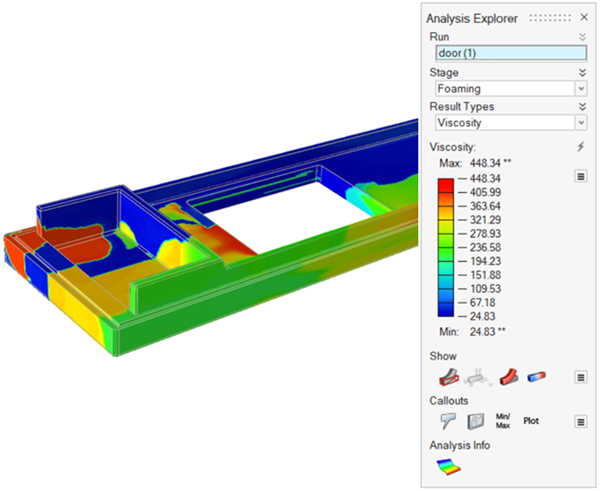

Foaming Results

Review material behavior through the foaming stage. Result types for this stage include: Temperature, Head ID, Material ID, Density, Polyol [mg KOH], Pressure, Velocity, Isocyanate [wt%], and Viscosity.

| Result Type | Description |

|---|---|

| Temperature | Review the temperature evolution of the material during the

foaming stage. |

| Head ID | Review the foaming results for material coming from a

particular nozzle. |

| Material ID | Review results for a particular material. |

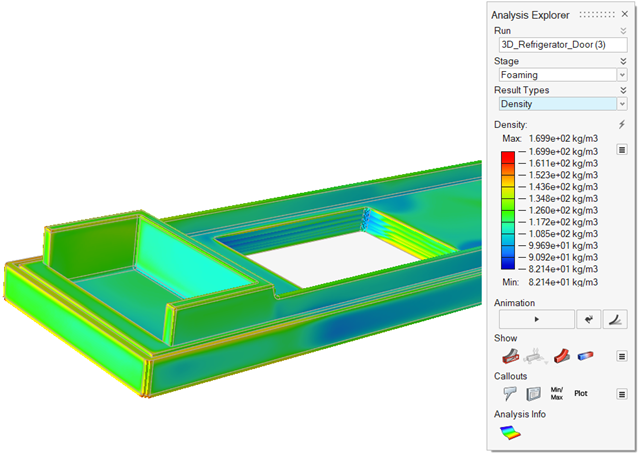

| Density | Consider material density through the progression of the

foaming stage. |

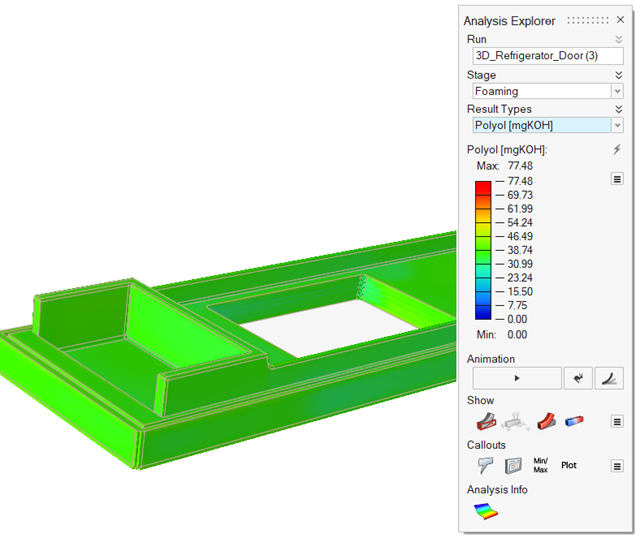

| Polyol [mg KOH] | Review levels of polyol in the material. |

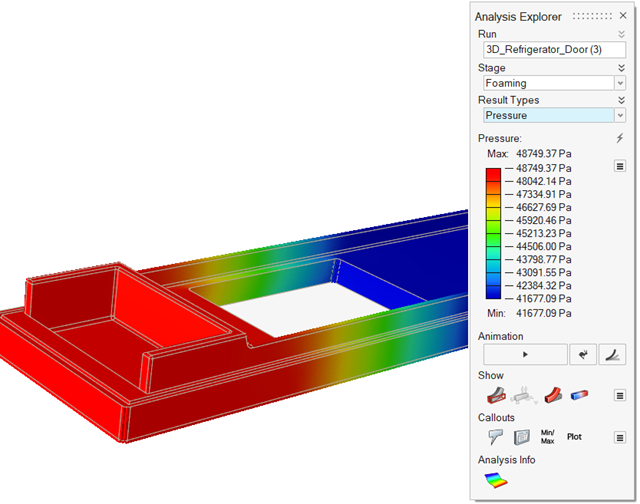

| Pressure | Review the impact of pressure on the material during the foaming stage.  |

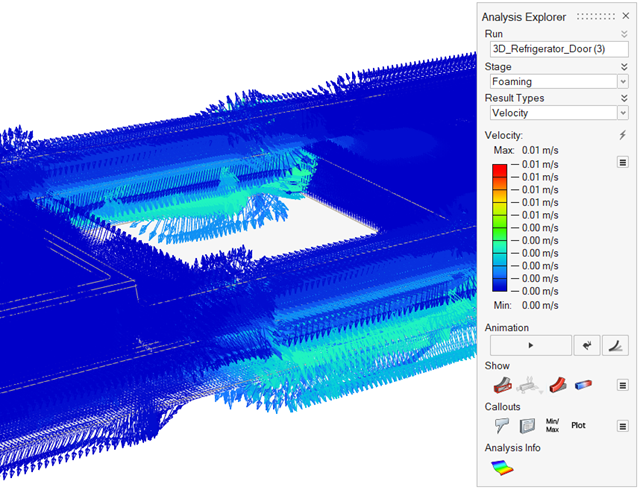

| Velocity | Review the foaming process, which is represented with vectors, to detect turbulences and velocities in the material.  |

| Isocyanate [wt%] | Review the of isocyanate levels that remain in the

polyurethane material. |

| Viscosity | Review the dynamic viscosity of the polyurethane

material. |

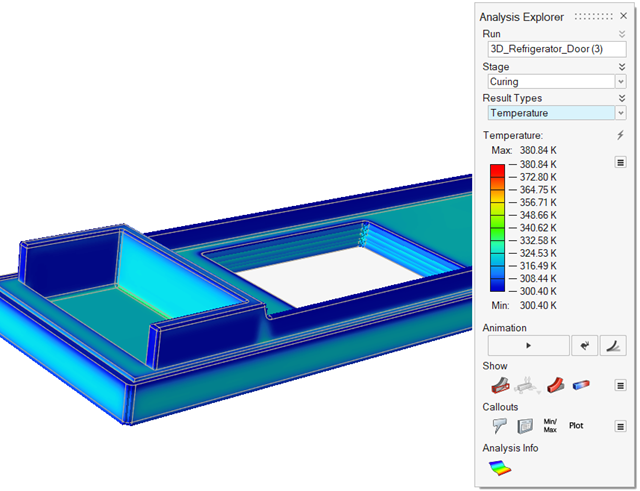

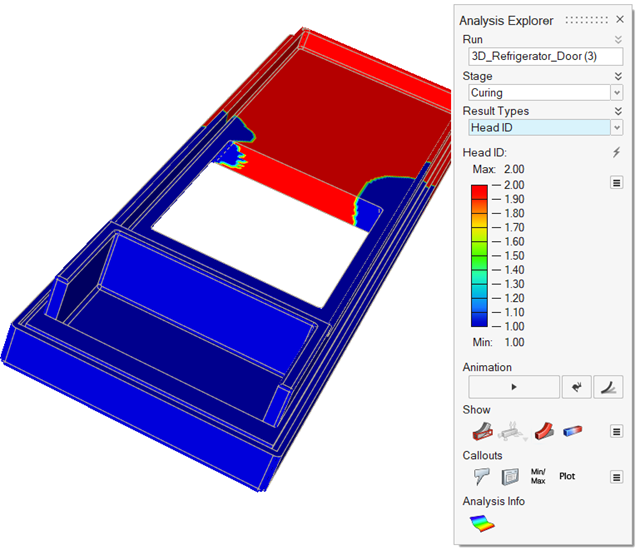

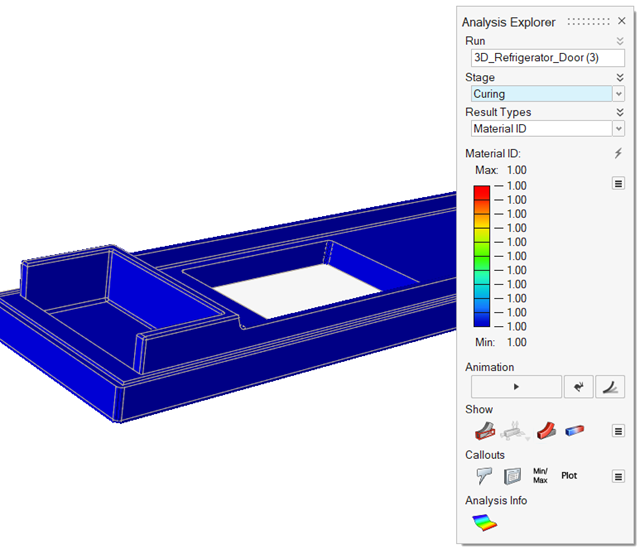

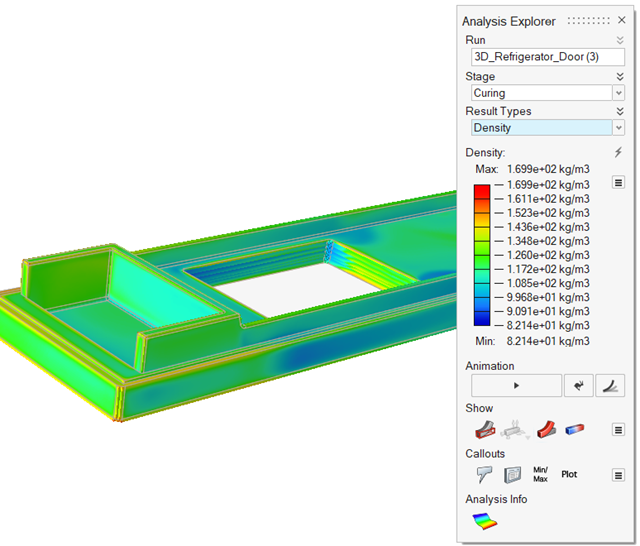

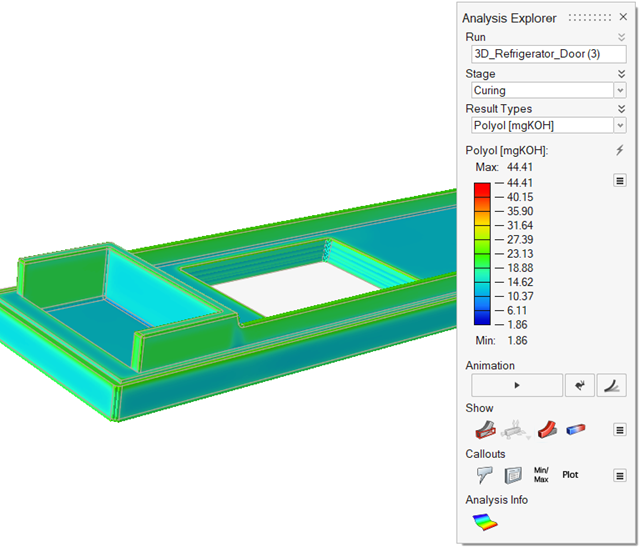

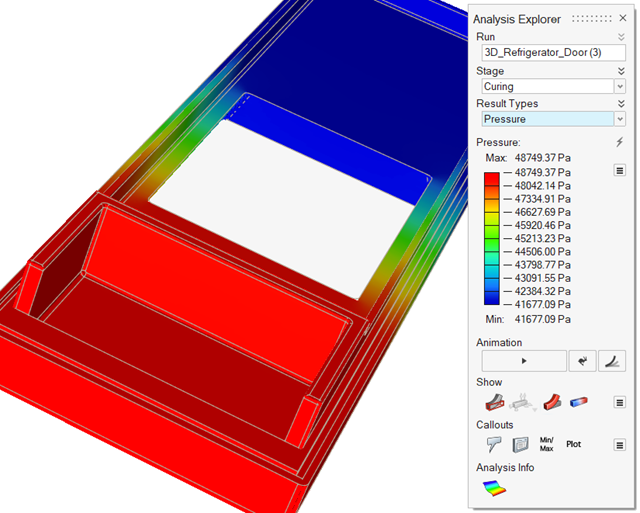

Curing Results

Review material behavior through the curing stage. Result types for this stage include: Temperature, Head ID, Material ID, Density, Polyol [mg KOH], Pressure, Isocyanate [wt%], and Viscosity.

| Result Type | Description |

|---|---|

| Temperature | Review the temperature evolution of the material during the

curing stage. Check regions for excessive heating or

cooling. |

| Head ID | Review curing results for the material coming from a

particular nozzle. |

| Material ID | Review the curing results for a particular material. |

| Density | Consider material density during the curing stage. |

| Polyol [mgKOH] | Review levels of polyol in the polyurethane material. |

| Pressure | Review the impact of pressure on the material during the

curing stage. |

| Isocyanate [wt%] | Review the of isocyanate levels that remain in the

polyurethane material. |

| Viscosity | Review the dynamic viscosity of the polyurethane material. |

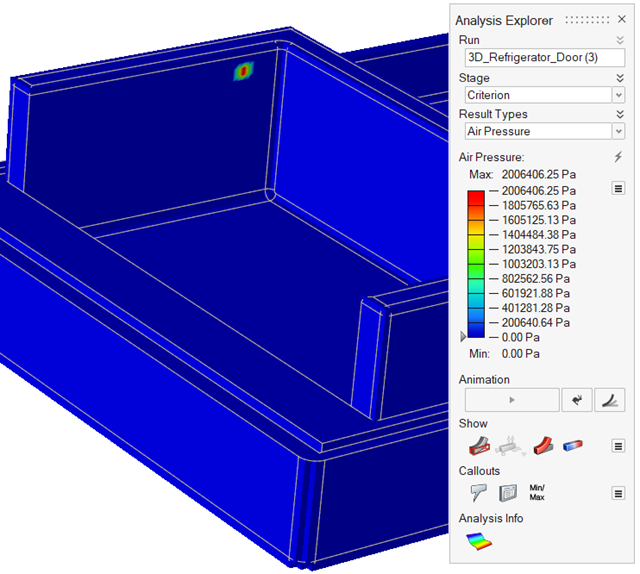

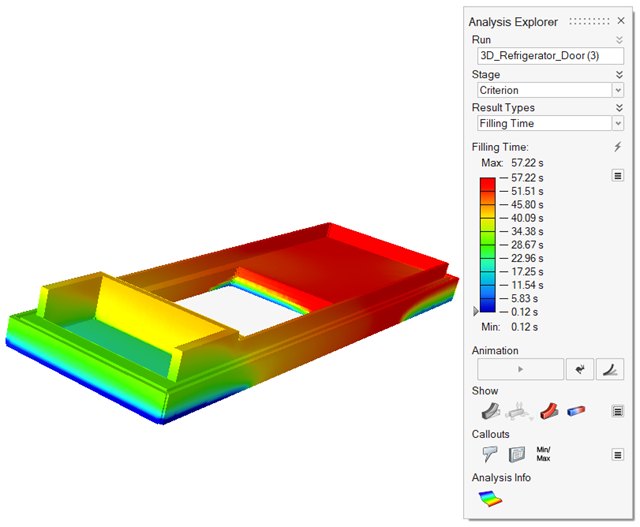

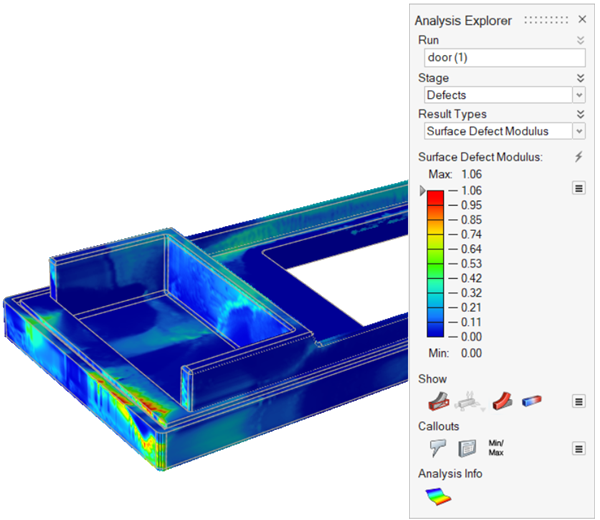

Defects Results

Review a range of defects that can occur at the end of the foaming process. Result types for this stage include: Air Pressure, Filling Time, Surface Defect Modulus, and Shrinkage Defect Modulus.

| Option | Description |

|---|---|

| Air Pressure | Display the accumulated air pressure effects on the part at

the end of the simulation. Look for porosity and void

defects. |

| Filling Time | Review the time the material takes to reach different areas of the mold. Consider adjustments to the nozzle paths and tooling.  |

| Option | Description |

|---|---|

| Surface Defect Modulus | Review the surface of the foam part for coarseness, toughness

and melting that could be due to high mold temperatures, poor

sealing, undried demolding spray, or contaminants. Consider

controlling the mold temperature or modifying the sealing

process. These surface defects can occur when a highly viscous

foam flows through the mold. |

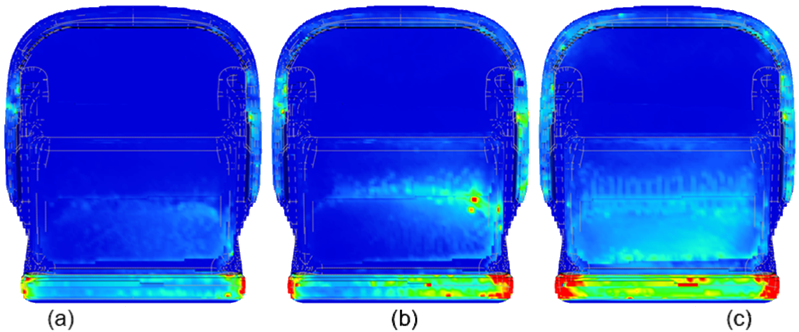

The Surface Defect Modulus is dimensionless, and the result

is displayed only on the surface between the part and mold. The

following example, where (a) is 20℃, (b) is 40℃, and (c) is 60℃,

shows a defect area that increases as the mold temperature

increases. |

|

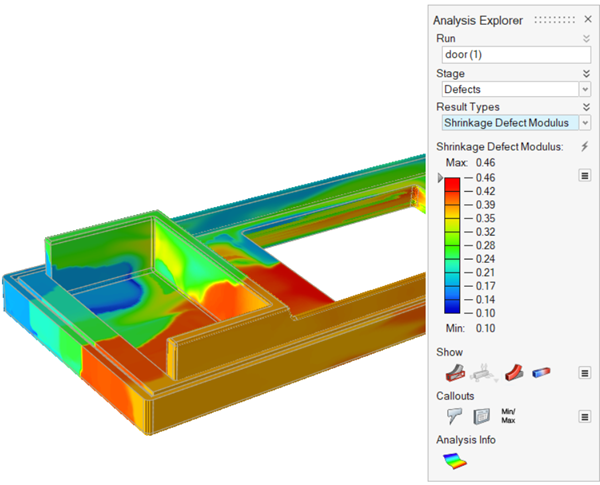

| Shrinkage Defect Modulus | To produce results that predict the Shrinkage Defect Modulus,

you must select Time as an ending

condition when defining the Process Parameters for your

analysis. A shrinkage defect can occur if the polyurethane

foam is too soft during the molding process or after

demolding. Shrinkage can occur due to over-packing, slow

gelling, and low index. Note that the shrinkage defect model

is appropriate for flexible, polyurethane foam only, not

rigid polyurethane foam.

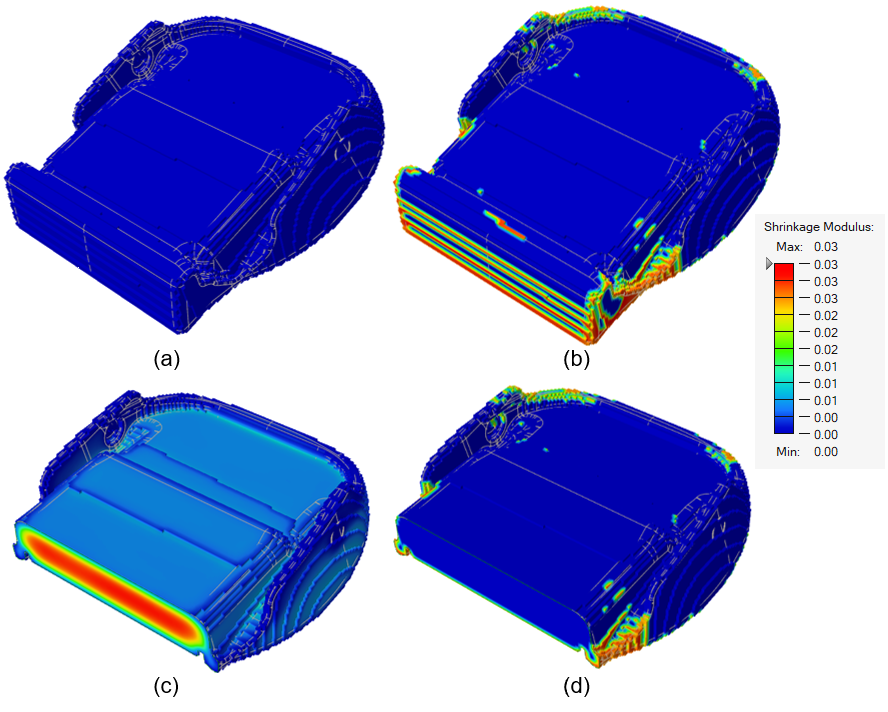

The following examples show model results where (a) the mold is 40℃, (b) the mold is 20℃, (c) the temperature is shown through the cross-section of the part, and (d) the mold is 20℃ and the shrinkage modulus is shown. No shrinkage occurs when

the mold temperature is 40℃ (a). However, when the mold

temperature dips to 20℃, shrinkage occurs as shown in (b).

Looking at the cross-section (c), shrinkage occurs mainly on

the outer surface of the part because the surface

temperature is lower than the core temperature.

|